Global Leaders in EV Battery Recycling Initiatives

North America: Advancing Sustainable Recycling Solutions

North American innovators are transforming battery recycling through groundbreaking technologies that recover up to 95% of critical materials. The region's approach combines advanced hydrometallurgical techniques with closed-loop systems that dramatically reduce environmental footprints. What sets North America apart is its unique combination of private sector innovation and government support creating an ecosystem for sustainable battery solutions.

Beyond technological advancements, the region has implemented progressive policies requiring manufacturers to handle battery disposal. These regulations, coupled with substantial research funding, are building domestic supply chains for essential battery components. The result is a growing industry that addresses both environmental concerns and national resource security.

Europe: Setting the Gold Standard in Battery Regulation

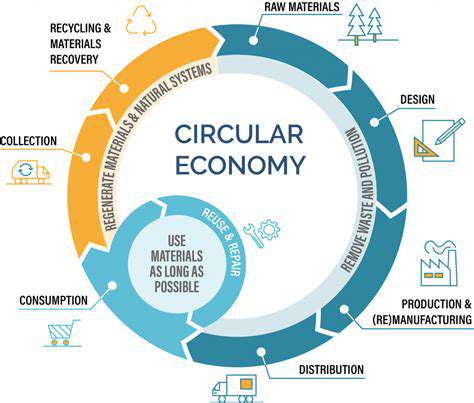

European nations have established the world's most comprehensive battery recycling framework through the EU Battery Directive. This legislation mandates strict recycling efficiency targets and holds producers accountable for product lifecycles. Europe's circular economy model demonstrates how policy can drive industry-wide change toward sustainability.

The continent's approach extends beyond regulations, with significant investments in battery refurbishment facilities that extend product lifespans. Collaborative research projects between universities and manufacturers are developing standardized recycling protocols that maintain safety while maximizing material recovery. These initiatives position Europe as the global benchmark for responsible battery management.

Breakthrough Technologies Reshaping Battery Recycling

Revolutionary Battery Chemistry Developments

Cutting-edge lithium-ion technologies now incorporate novel composite materials that enhance both performance and recyclability. Researchers have made significant progress with silicon-graphite anodes that increase energy capacity while using more abundant materials. These innovations directly address two major consumer concerns: vehicle range and long-term battery value.

The emergence of hybrid battery systems combining different lithium technologies offers unprecedented flexibility. These multi-chemistry solutions represent a fundamental shift in how we design batteries for both performance and end-of-life recovery. Manufacturers are particularly excited about new cathode formulations that reduce reliance on scarce metals without compromising power output.

Intelligent Battery Management Evolution

Modern Battery Management Systems (BMS) now incorporate predictive analytics that can forecast battery health with remarkable accuracy. These systems don't just monitor performance - they actively optimize charging patterns to extend usable life. Advanced BMS technology is proving crucial for determining when batteries should be repurposed rather than recycled.

The integration of blockchain technology into BMS creates tamper-proof records of battery history, significantly improving the used battery market. This transparency builds confidence in second-life applications and helps recyclers better assess incoming battery conditions.

The Solid-State Battery Revolution

Solid-state technology represents the most significant leap in battery safety and recyclability in decades. By eliminating liquid electrolytes, these batteries dramatically reduce fire risks while enabling simpler disassembly processes. Industry analysts predict solid-state batteries could cut recycling costs by up to 40% compared to current lithium-ion systems.

Major automakers are racing to commercialize solid-state designs that promise faster charging and longer lifecycles. The simplified material composition of these batteries makes them particularly attractive from a recycling standpoint, potentially revolutionizing how we recover battery materials.

Building Sustainable Battery Ecosystems

Comprehensive Policy Development

Effective policy frameworks must balance environmental protection with economic viability. Leading jurisdictions are implementing extended producer responsibility (EPR) schemes that hold manufacturers accountable for battery end-of-life. These policies create financial incentives for designing more recyclable products while funding collection infrastructure.

Forward-thinking regulations now mandate minimum recycled content in new batteries, creating guaranteed markets for recovered materials. This closed-loop approach transforms recycling from a cost center to a value-generating component of battery production.

Cross-Industry Collaboration Models

The most successful recycling programs emerge from partnerships across the entire battery value chain. Automakers, battery producers, and recyclers are forming joint ventures to share technical knowledge and infrastructure costs. These collaborations are accelerating the development of standardized battery designs that simplify disassembly and material recovery.

Industry consortia are establishing common protocols for battery health assessment, which is critical for determining whether units should be refurbished or recycled. Such cooperation helps create efficient secondary markets that maximize battery value before final recycling.

Economic Models for Recycling Growth

Innovative financing mechanisms are emerging to support recycling infrastructure development. Green bonds specifically targeting battery recycling projects have attracted significant institutional investment. Some governments are implementing advanced recycling fees at point of sale, creating dedicated funding streams for recycling operations.

The most progressive models treat spent batteries as strategic assets rather than waste. By valuing batteries for their material content, these approaches make recycling economically self-sustaining without requiring ongoing subsidies.

Overcoming Obstacles in Battery Recycling

Technical Challenges in Material Recovery

The diversity of battery chemistries presents complex challenges for recyclers. Current processes must constantly adapt to handle new electrode formulations and cell designs. Research focuses on developing flexible recycling methods that can accommodate evolving battery technologies without requiring complete process overhauls.

Particular attention is being paid to recovering high-purity materials that meet battery-grade specifications. The industry is moving beyond simple metal recovery to developing processes that can directly regenerate cathode materials, significantly reducing the energy needed to produce new batteries.

Global Standardization Efforts

International organizations are working to harmonize battery recycling standards across jurisdictions. These efforts focus on creating common definitions for battery states (end-of-life vs. reusable), standardized labeling systems, and uniform safety protocols. Such standardization is critical for developing efficient global recycling networks that can handle increasing battery volumes.

Emerging digital passport systems for batteries will provide detailed composition data to recyclers, dramatically improving recovery rates. These systems, combined with international material quality standards, will facilitate cross-border battery material flows while ensuring environmental protection.