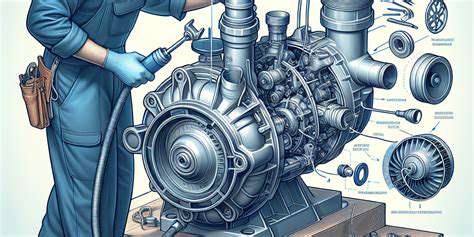

Material Selection Criteria

When engineers embark on any project, selecting appropriate materials forms the foundation of success. The process demands careful evaluation of multiple variables, including the material's intended use, environmental exposure, and performance expectations. Overlooking these fundamental considerations can lead to catastrophic project failures. Beyond basic mechanical properties like tensile strength and durability, professionals must examine corrosion resistance, thermal expansion coefficients, and fatigue limits through rigorous testing.

Modern material selection extends beyond pure functionality. Regulatory compliance, supply chain stability, and ethical sourcing now play equally important roles. Materials containing conflict minerals or those linked to environmental destruction increasingly face restrictions across global markets. Forward-thinking organizations conduct thorough life-cycle analyses, weighing factors from extraction impacts to end-of-life recyclability before finalizing their choices.

Performance Requirements

Every engineering application carries unique demands that dictate material specifications. Aerospace components, for instance, require exceptional strength-to-weight ratios, while medical implants need biocompatibility above all else. Precisely quantifying these needs through measurable parameters separates successful projects from costly failures. Engineers employ advanced simulation tools to predict how candidate materials will behave under expected operating stresses, temperatures, and chemical exposures.

The longevity equation introduces additional complexity. Materials must maintain integrity through years of cyclic loading, potential impact events, and environmental degradation. Accelerated aging tests that simulate decades of use in condensed timeframes have become industry standard for critical applications. Only materials demonstrating predictable performance degradation patterns receive consideration for long-service installations.

Cost and Availability

While technical specifications dominate early discussions, economic realities ultimately shape material decisions. The true cost equation extends far beyond purchase price per kilogram, encompassing machining requirements, waste factors, and even disposal costs. Advanced composites might offer superior performance but prove economically unfeasible when factoring in specialized tooling and skilled labor demands.

Global supply networks introduce another layer of complexity. A material's theoretical advantages become irrelevant if reliable suppliers can't meet production schedules. Smart organizations develop contingency plans, identifying alternative materials and qualifying backup vendors during the design phase rather than during supply crises. Just-in-time inventory systems demand particular attention to material lead times and regional availability.

Sustainability and Environmental Impact

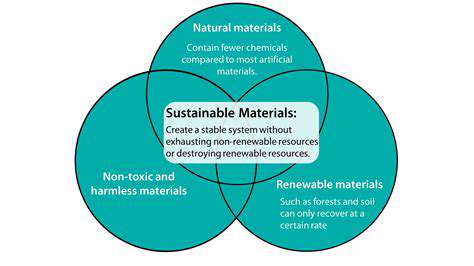

The sustainability revolution has fundamentally transformed material selection paradigms. Progressive firms now evaluate environmental metrics with the same rigor as mechanical properties. Life-cycle assessments track every gram of carbon emitted from extraction through manufacturing to final disposal. Materials contributing to circular economies—those designed for disassembly and reuse—receive preferential consideration across industries.

Innovative solutions are emerging at remarkable speed. Mushroom-based packaging replaces polystyrene, while graphene-enhanced composites reduce material needs through superior strength. The most forward-thinking companies now view sustainability not as a constraint but as a catalyst for innovation and competitive advantage. They actively participate in material development consortia, shaping the next generation of eco-conscious engineering solutions.

Minimizing Waste and Optimizing Production Processes

Minimizing Food Waste at Home

The modern kitchen presents numerous opportunities for waste reduction through intelligent practices. Strategic meal planning forms the cornerstone of effective food management, transforming chaotic grocery trips into precision operations. Savvy shoppers combine digital inventory tools with traditional preservation techniques, extending ingredient viability through proper temperature zoning and humidity control in refrigerators.

Understanding food biochemistry unlocks additional preservation strategies. Ethylene-sensitive produce like leafy greens requires isolation from gas-emitting fruits, while vacuum sealing dramatically slows oxidation in proteins. Fermentation and pickling techniques, once household staples, are experiencing renewed interest as both waste-reduction and flavor-enhancement methods.

Optimizing Produce Storage for Longevity

Different plant tissues demand customized storage approaches for maximum shelf life. Root vegetables maintain crispness in high-humidity coolers, while tropical fruits suffer chilling injury below critical temperatures. The science of controlled atmosphere storage, once exclusive to commercial operations, now informs home preservation practices through smart refrigerator technologies.

Innovative storage solutions continue emerging. Beeswax wraps replace plastic films, allowing produce to breathe while maintaining moisture. Ceramic storage eggs regulate humidity for delicate mushrooms and berries. These solutions demonstrate how ancient preservation wisdom combines with modern materials science to combat food waste.

Practical Strategies for Preventing Package Waste

The packaging revolution requires consumers to become discerning participants rather than passive recipients. Bulk purchasing with reusable containers cuts packaging waste by up to 90% compared to conventional retail options. Innovative stores now offer naked product sections where shoppers fill their own vessels with everything from rice to shampoo, supported by digital weighing systems.

Corporate responsibility complements individual action. Major brands increasingly adopt mono-material packaging designs that simplify recycling. The rise of plant-based plastics and edible packaging films points toward a future where packaging becomes part of the solution rather than the problem. Consumers voting with their wallets accelerate this positive transformation across industries.

In-situ resource utilization (ISRU) represents humanity's most ambitious step toward sustainable space exploration. This approach mirrors Earth's growing circular economy principles in the cosmos. The implications extend far beyond cost savings, potentially enabling permanent extraterrestrial settlements. Processing lunar regolith into construction materials or extracting water from asteroid ice could reduce launch masses by orders of magnitude. These technologies, currently under active development by space agencies worldwide, may soon transform science fiction into operational reality.