Bio-Based Lubricants: An Introduction

The lubrication industry is undergoing a quiet revolution as plant-derived alternatives challenge petroleum-based products. These advanced formulations harness nature's chemistry to provide effective lubrication while dramatically reducing environmental harm. By turning to renewable feedstocks like soybean or canola oil, manufacturers create products that perform comparably to conventional lubricants without depleting finite resources.

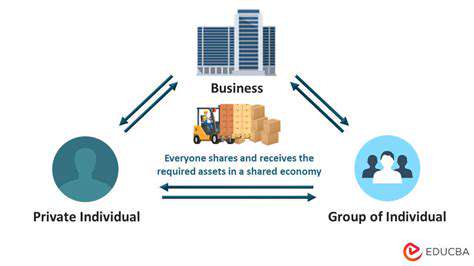

Market demand for these alternatives surges as industries seek ways to reduce their carbon footprint. Bio-lubricants offer a practical solution that aligns with circular economy principles, where waste minimization and resource efficiency become standard practice. Continuous improvements in production techniques are narrowing the performance and cost gaps with traditional options.

Key Benefits of Plant-Derived Lubricants

Environmental advantages distinguish bio-lubricants from conventional products. Their renewable origins mean significantly lower lifecycle carbon emissions—a critical factor in climate change mitigation. Shifting to these alternatives helps break dependence on petroleum while supporting agricultural economies that produce the raw materials.

Performance tests increasingly confirm that bio-based options match or exceed petroleum products in many applications. Advanced formulations now deliver equivalent protection for machinery while offering additional benefits like improved biodegradability. This performance parity makes adoption feasible across multiple industries without compromising equipment reliability.

Regional sourcing opportunities present another advantage. Locally-produced bio-lubricants reduce transportation emissions while strengthening rural economies. This decentralized model enhances supply chain resilience and keeps more economic value within production communities.

Overcoming Adoption Barriers

Cost remains the primary obstacle to widespread bio-lubricant adoption, as production scales haven't yet matched petroleum's economies. Ongoing research focuses on optimizing extraction and refinement processes to achieve price parity with conventional options.

Performance consistency across diverse operating conditions requires continued refinement. Standardization efforts aim to ensure reliable performance regardless of application specifics, building user confidence in these innovative products.

The future looks bright as researchers tackle these challenges. Breakthroughs in biotechnology and process engineering promise to unlock bio-lubricants' full potential, positioning them as mainstream alternatives within the decade. Sustained investment and innovation will be crucial to overcoming remaining technical and economic hurdles.

Beyond Oil: Eco-Friendly Fluids for a Comprehensive Approach

Moving Past Petroleum Dependency

The transportation sector's century-long reliance on petroleum products is giving way to a more diverse, sustainable fluid ecosystem. Environmental regulations, technological advances, and shifting consumer expectations drive this transformation toward greener alternatives that don't sacrifice performance.

Advanced Synthetic Solutions

Engineered lubricants represent a bridge between conventional and future fluid technologies. These precisely formulated products often outperform mineral oils while reducing environmental impact through extended service intervals and improved efficiency. Their controlled manufacturing processes minimize ecological harm compared to crude oil refining.

Nature-Inspired Fluid Innovations

Plant-derived automotive fluids continue gaining traction as processing techniques improve. Current formulations leverage agricultural byproducts and specialized oil crops to create high-performance alternatives that biodegrade more readily than petroleum counterparts. Continued refinement aims to enhance their stability across temperature extremes.

Greener Cooling Systems

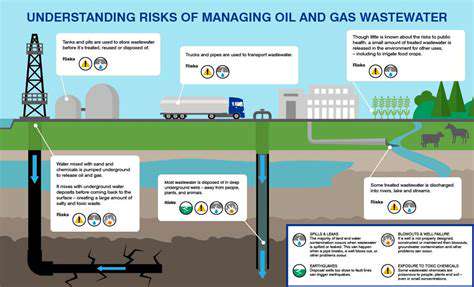

Traditional engine coolants contain toxic ethylene glycol, posing serious environmental risks if leaked. New biodegradable formulations maintain critical thermal properties while dramatically reducing ecological toxicity. These alternatives help prevent groundwater contamination when vehicles eventually reach end-of-life.

Next-Generation Fluid Science

Cutting-edge research explores nanotechnology and other advanced approaches to create fluids that actively reduce energy consumption while protecting components. These innovations promise to make vehicles more efficient while minimizing their environmental footprint throughout the usage cycle.

Closing the Recycling Loop

Effective fluid management extends beyond initial use to include collection, purification, and reuse systems. Advanced re-refining technologies now enable multiple lifecycles for many automotive fluids, significantly reducing virgin material requirements and preventing environmental contamination.

Educating for Change

Consumer adoption remains the final hurdle for widespread sustainable fluid implementation. Clear communication about performance parity, environmental benefits, and potential cost savings will accelerate market acceptance. Industry and policymakers must collaborate to make these options accessible and affordable.