Plant-derived bioplastics, sourced from renewable materials such as corn derivatives or sugar cane, present a viable substitute for petroleum-based plastic products. These innovative materials typically demonstrate substantially reduced carbon emissions during production and decomposition phases, thereby diminishing their environmental consequences. However, assessing the true ecological benefits of bioplastics requires nuanced consideration. Critical factors including raw material sourcing, manufacturing techniques, and disposal protocols all significantly influence their overall environmental performance. Continued scientific investigation and technological refinement remain imperative to optimize bioplastic production and validate their long-term sustainability.

Compostable Polymers: Complex Environmental Implications

Engineered compostable plastics are specifically formulated to decompose into natural elements under controlled composting conditions. While theoretically advantageous, practical implementation reveals numerous complexities. Genuine compostability necessitates specialized processing facilities frequently unavailable in standard waste management systems. Additionally, certain production methods for these materials may still depend on non-renewable energy sources, potentially offsetting their environmental advantages. The widespread success of compostable plastics as a sustainable alternative hinges on adequate composting infrastructure and consumer education regarding proper disposal protocols.

Fungal-Based Materials: Groundbreaking Innovation

Cutting-edge material science breakthroughs have yielded plastic alternatives derived from fungal mycelium networks. This novel approach offers genuine sustainability potential by utilizing abundant, renewable biological resources. Mycelium-derived materials demonstrate natural biodegradability and can be customized for specific functional requirements. However, current production capacities and market penetration remain limited. Additional research and technological development are essential to fully realize the promise of these revolutionary materials and overcome barriers to large-scale commercialization.

Natural Plant Fibers: Time-Tested Sustainability

Traditional plant-derived fibers including cotton, hemp, and jute have served humanity for centuries in textile and manufacturing applications. These naturally occurring materials offer inherent biodegradability and typically require less energy to produce than synthetic alternatives. Incorporating plant-based fibers can decrease dependence on petroleum-derived synthetics while promoting more sustainable supply chains. However, comprehensive sustainability assessments must account for agricultural land use, water requirements, and processing methodologies to ensure long-term ecological viability.

Recycled Polymers: Waste Stream Transformation

Effective recycling of existing plastic waste represents a critical element of comprehensive sustainability strategies. Progressive recycling technologies continue advancing, enabling efficient recovery of valuable materials from discarded plastic products. This approach reduces demand for virgin materials while significantly lowering overall environmental impacts. Persistent challenges remain in waste sorting systems, processing efficiency, and maintaining recycled material quality standards across diverse applications. Successful implementation requires active consumer participation in recycling programs.

Paper Substitutes: Emphasizing Renewability

Developing alternatives to conventional tree-based paper products constitutes an essential sustainability initiative. Materials such as bamboo fibers, agricultural byproducts, and recycled paper content offer promising options that alleviate pressure on forest ecosystems while promoting renewable resource utilization. However, complete environmental assessments must evaluate production processes regarding water consumption, land management practices, and chemical usage to prevent unintended ecological consequences.

Next-Generation Polymers: Engineering Sustainability

Ongoing research into advanced polymer chemistry enables creation of plastic materials with enhanced environmental characteristics, including improved biodegradability and recyclability. Scientists continue exploring novel molecular structures and manufacturing techniques to develop materials combining durability with ecological benefits. While these innovations show tremendous promise, current limitations include higher initial costs and the need for extensive testing to validate performance across various applications.

High-Performance Ceramics for Superior Functionality

Advanced Ceramics: Ecological Material Selection

Technical ceramics, classified as inorganic non-metallic substances, are experiencing rapid adoption across multiple industries due to their extraordinary characteristics. These materials, frequently derived from naturally occurring elements, present sustainable advantages over conventional materials by decreasing dependence on finite resources and minimizing environmental impact throughout their lifecycle. Their inherent robustness, hardness, and thermal stability make them particularly suitable for applications demanding exceptional durability and performance.

Remarkable Characteristics for Varied Applications

Advanced ceramic materials demonstrate an impressive array of properties, including outstanding strength-to-weight ratios, superior wear resistance, and exceptional chemical stability. These attributes render them appropriate for numerous applications. Their capacity to endure extreme thermal conditions and corrosive environments further expands their utility, establishing them as indispensable components in high-performance sectors including aerospace, energy generation, and medical technology.

From state-of-the-art propulsion system components to sophisticated biomedical implants, the adaptability of technical ceramics is truly extraordinary. Their unique properties continue to redefine industry standards while creating new opportunities for innovation and operational efficiency.

Environmentally Responsible Manufacturing Techniques

Modern ceramic production increasingly incorporates ecologically sound manufacturing processes. Contemporary fabrication methods emphasize waste reduction, energy efficiency, and utilization of abundant raw materials. These sustainable practices result in significantly reduced environmental impact compared to traditional manufacturing approaches. This environmental consideration proves critical for ensuring the long-term viability and market acceptance of technical ceramic products.

Enhanced Longevity and Reliability

A primary advantage of technical ceramics lies in their exceptional durability. Their natural resistance to abrasion, chemical corrosion, and extreme temperatures translates to extended product lifecycles. This characteristic yields reduced maintenance demands, lower operational expenses, and prolonged service duration relative to conventional materials, supporting more sustainable long-term strategies. Such longevity proves particularly valuable for components operating in challenging environments.

Superior Performance Under Extreme Conditions

Technical ceramics excel in applications involving extreme operational parameters. Their ability to withstand intense heat, extreme pressure, and corrosive media makes them essential for high-performance engines and advanced aerospace components. These materials consistently deliver optimal performance in demanding conditions, ensuring exceptional reliability and efficiency while frequently enabling significant performance enhancements.

Economic Efficiency and Commercial Viability

Despite their advanced properties, technical ceramics are becoming increasingly cost-effective. Manufacturing process improvements and production scaling continue to reduce unit costs. This improved affordability, combined with long-term durability and performance benefits, makes these materials economically attractive for numerous applications. The substantial lifecycle cost savings frequently justify initial investment outlays, establishing them as compelling alternatives over extended periods.

Diminished Ecological Footprint

Reduced dependence on scarce resources and adoption of sustainable production methods contribute to lower environmental impact across the entire product lifecycle of technical ceramics. This characteristic perfectly aligns with growing global emphasis on sustainability and circular economy principles. The minimized waste generation and reduced energy consumption during manufacturing and usage make these materials increasingly appealing to environmentally conscious consumers and businesses.

The Future of Sustainable Materials in Automotive Electronics

Innovative Biological Materials

The pursuit of environmentally preferable alternatives to conventional materials is stimulating remarkable innovation in biologically-derived substances. These materials, obtained from renewable sources including plant matter and marine organisms, offer promising pathways to decrease fossil fuel dependence and minimize ecological harm. The capacity of bio-based materials to supplant petroleum-derived plastics in numerous applications represents a transformative opportunity. This transition could substantially reduce greenhouse gas emissions linked with traditional plastic production.

Research teams are vigorously investigating biopolymer potential - macromolecules produced from renewable biological sources. These substances exhibit distinctive properties that can be customized for specific uses, presenting exciting prospects for sustainable packaging, building materials, and fabrics. Moreover, developing efficient and cost-competitive production methods for these bio-based materials remains essential for broad market acceptance.

Next-Generation Recycling Solutions

Enhancing recycling technologies proves critical for waste reduction and optimal material utilization. Advanced methodologies are emerging to extract valuable components from diverse waste streams, including synthetic polymers, metals, and textiles. These innovations aim to convert waste materials into reusable resources, thereby decreasing demand for virgin material extraction and associated environmental damage.

Creating more sophisticated sorting and processing techniques remains imperative for efficient recycling of complex material combinations. Additionally, establishing closed-loop systems where recycled materials are directly reintegrated into manufacturing processes will prove instrumental in achieving true sustainability.

Principles of Sustainable Design

Implementing sustainable design philosophies across the entire product lifecycle remains essential for minimizing ecological impact. This approach prioritizes material reduction, sustainable material selection, and designing products for simplified disassembly and recycling. Sustainable design principles must permeate all product development phases, from initial conception through end-of-life management.

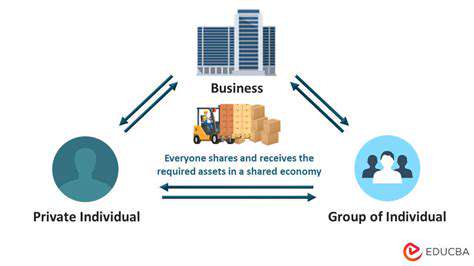

Circular Economic Models

Transitioning to circular economic principles proves vital for achieving sustainable material utilization. This model emphasizes waste minimization, material reuse, and resource recovery to establish closed-loop systems. By facilitating material reuse and recycling, we can dramatically decrease reliance on virgin resource extraction. This strategy will substantially reduce manufacturing-related environmental impacts.

Successful circular economic models also necessitate fundamental behavioral shifts among consumers, promoting product longevity, repairability, and adoption of reusable product designs. This evolution in consumer mentality will prove critical for circular economy success.

Policy Frameworks and Economic Incentives

Government policies and financial incentives play pivotal roles in accelerating the transition to sustainable materials. Support for sustainable material research, tax incentives for circular economy adoption, and regulations restricting hazardous substances in products will collectively contribute to environmental progress. Public sector support remains essential for expediting the shift toward sustainable material economies.

Policy measures encouraging sustainable practice adoption and innovative technology development will drive meaningful advancement in this crucial area. This governmental backing proves indispensable for overcoming challenges and fully realizing sustainable material potential.