Fuel Cell Vehicles: A Promising Future?

Hydrogen fuel cell vehicles present an intriguing zero-emission alternative, generating power through electrochemical reactions that emit only water vapor. While technically impressive, infrastructure hurdles and production costs currently limit their practicality. Ongoing research aims to overcome these barriers and position fuel cells as viable transportation solutions.

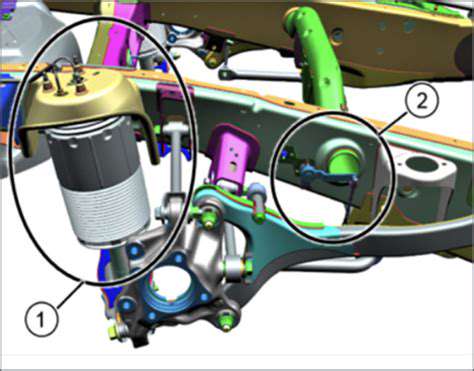

Hybrid Powertrains: Blending Efficiency and Performance

Hybrid systems offer a transitional solution, merging electric and combustion technologies. Their intelligent power management maximizes efficiency across diverse driving conditions. Regenerative braking captures otherwise wasted energy, while electric-only modes enable emission-free operation in urban environments.

Biofuels: Harnessing Nature's Resources

Plant-derived fuels provide renewable alternatives compatible with existing engines. However, sustainability concerns persist regarding agricultural impacts and energy-intensive production methods. Second-generation biofuels from non-food biomass may offer more environmentally responsible pathways.

Synthetic Fuels: A Technological Leap?

Carbon-neutral synthetic fuels could decarbonize conventional vehicles without requiring new infrastructure. Their viability hinges on renewable energy availability for production and cost competitiveness with conventional fuels.

Advanced Combustion Engine Technologies: Optimizing Existing Systems

While electrification progresses, cleaner combustion technologies continue evolving. Efficiency improvements and alternative fuel compatibility help reduce emissions from conventional vehicles during the transition period.

Australia's EV charging network currently operates like a jigsaw puzzle with missing pieces. Various providers offer incompatible solutions, creating a maze of apps, payment systems, and location databases that frustrate even tech-savvy drivers. This chaotic landscape represents one of the most significant psychological barriers to EV adoption nationwide. Imagine planning a road trip where every gas station required a different loyalty card - that's the reality EV drivers face today.

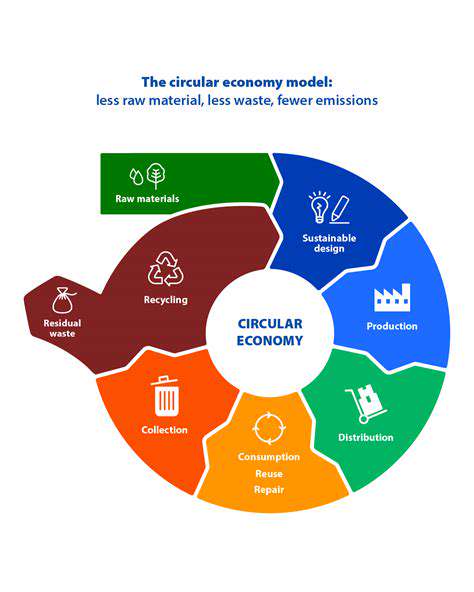

The Impact of Circular Economy Principles on Vehicle Lifecycles

Circular Economy Principles in Action

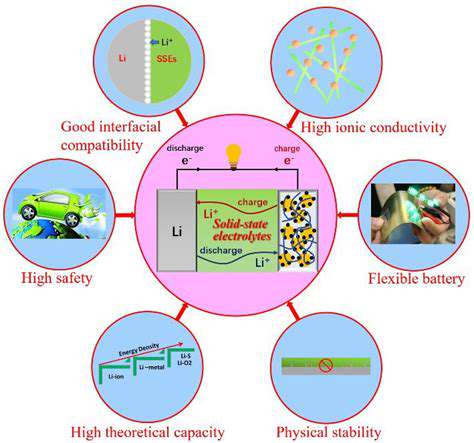

The circular economy model transforms traditional production paradigms by emphasizing resource recovery and extended product lifecycles. This systemic shift demands unprecedented collaboration across industries and supply chains, challenging conventional business models focused on linear consumption patterns.

Transitioning to circular systems requires rethinking product design at fundamental levels. Components must facilitate disassembly and material recovery while maintaining performance standards. Manufacturers face the dual challenge of meeting these requirements while controlling production costs.

Resource Efficiency and Waste Reduction

Smart resource management strategies minimize input requirements while maximizing output value. Design-for-disassembly principles enable efficient material recovery, creating closed-loop material flows that dramatically reduce waste generation.

Advanced sorting and processing technologies are revolutionizing recycling capabilities. These systems can separate complex material combinations found in modern vehicles, recovering high-purity materials for reuse in new production cycles.

Economic Opportunities and Societal Benefits

Circular models create new revenue streams through secondary material markets and service-based business models. These approaches can reduce manufacturing costs while generating employment in recycling and remanufacturing sectors, contributing to more resilient local economies.

Environmental benefits extend beyond waste reduction to include lower energy consumption and reduced emissions throughout product lifecycles. These systemic improvements contribute to broader sustainability goals while delivering tangible economic value.

Policy and Infrastructure Support

Effective circular economies require supportive regulatory frameworks that incentivize sustainable practices. Extended producer responsibility schemes and material recovery mandates encourage manufacturers to design for recyclability from inception.

Strategic infrastructure investments are critical for creating efficient material recovery networks. These systems must handle increasing material volumes while maintaining processing quality standards to enable true circularity.