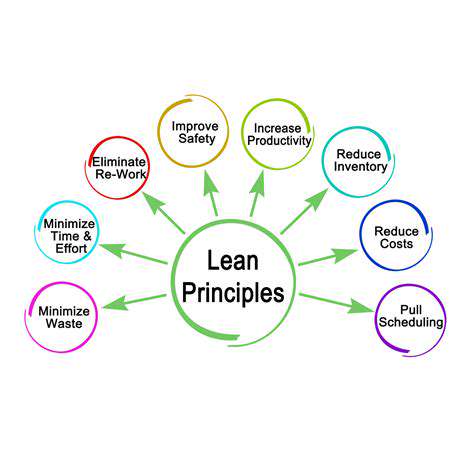

Lean Principles: Core Concepts

Lean principles, at their core, represent a methodology focused on eliminating waste and maximizing value in any process. This philosophy emphasizes continuous improvement and customer satisfaction as paramount goals. By streamlining operations and removing unnecessary steps, companies can significantly enhance efficiency and reduce costs. Lean principles are not just applicable to manufacturing; they can be applied to any area of business, from customer service to project management.

These principles are built on a foundation of understanding the customer's needs and delivering value in the most efficient and effective manner possible. This involves a deep understanding of the entire process, from the initial customer interaction to the final product delivery.

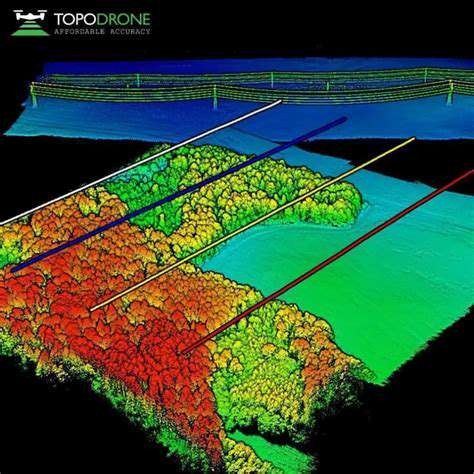

Value Stream Mapping: Visualizing Flow

Value stream mapping is a powerful tool within the Lean framework. It's a visual representation of all the steps involved in bringing a product or service to the customer. This map highlights areas of waste and bottlenecks, allowing for targeted improvements. Value stream mapping helps identify non-value-added activities and provides a clear roadmap for streamlining the entire process. This visual approach allows teams to easily identify where time and resources are being wasted.

By visualizing the entire process, from raw materials to the finished product, teams can pinpoint areas for improvement and implement solutions to enhance efficiency. This systematic approach allows for a comprehensive understanding of the flow of work.

Waste Identification: Removing Inefficiencies

A key aspect of Lean principles is waste identification. Waste, in the Lean context, encompasses any activity that does not add value to the product or service from the customer's perspective. This includes overproduction, waiting, transportation, inventory, motion, over-processing, and defects.

Identifying and eliminating these wastes is crucial for improving efficiency and reducing costs. By systematically identifying and eliminating waste, companies can significantly improve productivity and profitability. A thorough analysis of the process is essential to identify and eliminate waste effectively.

Kaizen: Continuous Improvement

Kaizen, a cornerstone of Lean, focuses on continuous improvement. It's a philosophy that encourages small, incremental changes over time. This approach promotes a culture of continuous learning and problem-solving, where employees at all levels are empowered to identify and implement improvements.

Kaizen fosters a culture of collaboration and innovation, driving improvements in efficiency and quality across the organization. This approach ensures that improvements are sustainable and deeply embedded in the organizational culture.

Just-in-Time Inventory: Minimizing Stock

Just-in-time (JIT) inventory management is a crucial element of Lean. It involves producing or acquiring goods only when they are needed, minimizing inventory levels and associated costs. This approach reduces storage space requirements and minimizes the risk of obsolescence.

By reducing inventory levels, companies can save money on storage costs, insurance, and potential losses due to spoilage or obsolescence. This approach ensures that resources are allocated efficiently and only to meet actual demand.

Pull Systems: Responding to Demand

Pull systems, a key component of Lean, are designed to respond to customer demand. Instead of producing goods in advance, a pull system waits for a signal or order from the downstream process to initiate production. This approach minimizes waste by only producing what is needed when it is needed.

This approach ensures that production is aligned with customer demand, avoiding overproduction and inventory buildup. By aligning production with actual demand, a pull system ensures that resources are utilized effectively and waste is minimized.

Cultivating a fertile ground for creativity requires a conscious effort to foster a mindset that embraces novelty and experimentation. This involves actively seeking out new experiences, challenging preconceived notions, and embracing the inherent uncertainty that often accompanies innovative thinking. Stepping outside of your comfort zone and exploring different perspectives can unlock a wealth of potential ideas that might otherwise remain hidden. This process of actively engaging with the world around you, questioning assumptions, and approaching problems from unusual angles can significantly enhance your creative output.