Optimizing Routes and Reducing Fuel Consumption

Improving Route Planning

Effective route planning is crucial for optimizing fuel consumption and reducing operational costs in fleet management. Telematics systems provide real-time data on traffic conditions, allowing drivers to adjust their routes dynamically. This proactive approach avoids congested areas, maximizing efficiency and minimizing unnecessary idling time. By analyzing historical data, telematics can identify optimal routes and suggest alternative paths based on various factors like speed limits, road closures, and weather conditions, ultimately improving fuel economy.

Real-Time Traffic Monitoring and Adjustments

The ability to monitor traffic conditions in real-time is a game-changer for fleet optimization. Telematics systems provide drivers with up-to-the-minute information on traffic congestion, allowing them to make informed decisions on the fly. This dynamic route adjustment reduces travel time and fuel consumption significantly, as drivers can avoid bottlenecks and congestion. The system can also suggest alternative routes based on the real-time data, ensuring that the fleet is always on the most efficient path.

Predictive Maintenance for Vehicle Optimization

Telematics data can be used to predict potential maintenance needs before they lead to costly breakdowns. By analyzing data on vehicle performance, such as speed, acceleration, braking patterns, and engine temperature, telematics systems can identify potential problems early on. This predictive maintenance capability allows for proactive scheduling of maintenance, reducing downtime and maximizing vehicle uptime. It also helps anticipate potential fuel efficiency issues, allowing for timely interventions and preventing further degradation of fuel economy.

Driver Behavior Analysis and Training

Telematics data provides valuable insights into driver behavior, enabling fleet managers to identify areas for improvement and implement targeted training programs. By tracking driving habits such as acceleration, braking, and speed, telematics can pinpoint instances of aggressive driving, which often lead to higher fuel consumption. Analyzing this data allows for the development of customized driver training programs focused on fuel-efficient driving techniques. This ultimately reduces fuel costs and improves overall safety within the fleet.

Fuel Consumption Monitoring and Reporting

Telematics systems offer detailed fuel consumption monitoring, enabling fleet managers to track fuel usage patterns and identify potential inefficiencies. By recording fuel consumption data alongside driving data, the system can pinpoint specific vehicles or drivers who are exhibiting higher-than-average fuel consumption. This analysis helps in identifying areas for improvement and implementing corrective measures. The comprehensive reports generated by telematics provide valuable insights into fuel economy trends, allowing for effective benchmarking and proactive cost management.

Integration with Other Fleet Management Tools

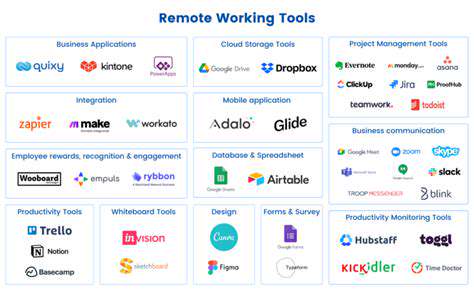

Telematics systems can be seamlessly integrated with other fleet management tools, providing a holistic view of operations. This integration allows for efficient data sharing and analysis across different platforms. For example, integrating telematics data with dispatch software can optimize scheduling and route planning, leading to even greater efficiency gains. This comprehensive approach to data management allows for a more streamlined and effective fleet management system, further reducing fuel consumption and improving overall operational performance.

Improving Maintenance and Repair Scheduling

Preventive Maintenance Strategies

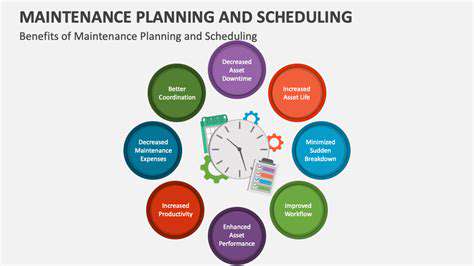

Implementing robust preventive maintenance schedules is crucial for minimizing unexpected breakdowns and extending the lifespan of equipment. Regular inspections, lubrication, and cleaning can identify potential issues before they escalate into major repairs. This proactive approach not only saves money on costly repairs but also ensures consistent production output and reduces downtime, a significant factor in overall operational efficiency.

Preventive maintenance encompasses a wide range of activities, from simple visual checks to more complex procedures like component replacements based on predetermined intervals. Establishing clear guidelines and procedures for each piece of equipment is paramount to maximizing the benefits of this strategy. A well-defined preventive maintenance program can significantly reduce the frequency and severity of equipment failures.

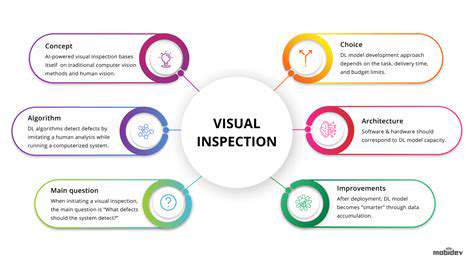

Predictive Maintenance Techniques

Predictive maintenance utilizes advanced technologies to anticipate potential equipment failures. Sensors and data analytics can monitor equipment performance in real-time, identifying subtle anomalies that might indicate an impending problem. This allows for proactive intervention, minimizing downtime and preventing costly breakdowns.

Employing predictive maintenance significantly reduces the need for reactive repairs, which can be disruptive and expensive. This approach involves collecting data from various sources, including vibration, temperature, and pressure sensors, and analyzing this data to identify patterns and predict potential failures.

Optimizing Repair Processes

Streamlining repair processes is essential for minimizing downtime and ensuring efficient resolution of equipment issues. Clear repair protocols, well-stocked parts inventories, and skilled technicians are all critical components of an efficient repair process. Properly trained personnel are critical to ensuring safety and quality in repairs. This involves providing comprehensive training programs and maintaining a safe working environment.

Importance of Skilled Technicians

Highly skilled and experienced technicians are the backbone of any effective maintenance and repair program. Investing in their training and development is a crucial step in ensuring the quality and efficiency of repairs. Specialized training programs focused on specific equipment types and repair techniques can significantly enhance the capabilities of technicians. This ensures that repairs are performed correctly the first time, preventing further issues and reducing the likelihood of recurrence.

Parts Management and Inventory

Effective parts management is essential for quick and efficient repairs. Maintaining accurate inventory records, optimizing storage space, and establishing clear procedures for ordering and receiving parts are crucial. A well-organized system for tracking parts usage and ordering ensures minimal disruptions to the repair process. This proactive approach can prevent costly delays and ensure that repairs are completed in a timely manner.

Safety Protocols in Maintenance

Safety should always be the top priority in any maintenance or repair activity. Implementing strict safety protocols, providing appropriate personal protective equipment (PPE), and ensuring adherence to safety regulations is vital. A safe work environment not only protects the technicians but also minimizes the risk of accidents and injuries. Regular safety training and drills can significantly reduce the risk of incidents during maintenance and repair procedures.

Cost-Benefit Analysis of Improvements

Evaluating the cost-benefit analysis of implementing these maintenance and repair improvements is essential for demonstrating the return on investment. Thorough documentation of repair costs, downtime, and productivity gains allows for a clear assessment of the financial impact of these strategies. This analysis can help justify the investment in new technologies, training, or equipment upgrades, providing a clear rationale for improvements.

Data-Driven Decision Making for Enhanced Business Performance

Data Collection and Preparation

Effective data-driven decision-making hinges on the quality and comprehensiveness of the data collected. This involves defining clear objectives and identifying the specific data points needed to achieve those objectives. Careful consideration must be given to the source of the data, ensuring its accuracy, reliability, and relevance to the problem at hand. Gathering data from multiple sources can enrich the insights derived, but potential discrepancies must be carefully addressed during the preparation phase. Furthermore, data preparation is crucial, encompassing tasks such as cleaning, transforming, and formatting the data to ensure consistency and usability for analysis.

Data cleaning involves identifying and correcting errors, inconsistencies, and missing values within the dataset. This process is essential to maintain data integrity and prevent misleading analysis results. Proper data transformation involves converting data into a suitable format for analysis, such as converting categorical data into numerical representations. Data formatting is vital for ensuring compatibility with various analytical tools and techniques. This meticulous preparation ensures the insights derived from the data are accurate and reliable.

Analysis Techniques and Tools

A range of analytical techniques can be employed to extract meaningful insights from the collected data. Statistical methods, such as regression analysis or hypothesis testing, can reveal correlations and dependencies between variables. Data visualization techniques, like charts and graphs, can effectively communicate complex patterns and trends to stakeholders. These visual representations make it easier to identify key insights and understand the underlying relationships within the data.

Choosing the appropriate analytical tools is essential for achieving accurate and reliable results. Specialized software packages offer a plethora of tools for data manipulation, analysis, and visualization. Understanding the limitations and capabilities of each tool is crucial for selecting the most suitable one for the specific task. This ensures that the chosen tools align with the project's objectives and the available resources.

Interpretation and Communication of Results

The analysis phase is not complete until the results are interpreted and communicated effectively. This involves drawing conclusions based on the observed patterns and trends in the data. It is important to consider the context and potential biases present in the data when formulating interpretations. Presenting the findings in a clear and concise manner, using appropriate visualizations and metrics, is crucial for conveying the insights effectively to stakeholders.

Effective communication of results requires tailoring the presentation to the audience's level of understanding. Using clear and concise language, along with compelling visuals, can significantly enhance understanding and engagement. Presenting the data in a user-friendly format, such as dashboards or reports, can enable stakeholders to quickly grasp the key takeaways and make informed decisions.

Implementation and Monitoring

The final step in the data-driven decision-making process involves implementing the insights gained from the analysis. This necessitates translating the findings into actionable strategies and plans. Careful consideration should be given to the potential impact of these strategies on various stakeholders and the overall business objectives. Successfully implementing these plans requires a well-defined action plan and clear communication channels to ensure everyone understands their roles and responsibilities.

Monitoring the effectiveness of the implemented strategies is crucial for optimizing performance and achieving desired outcomes. This involves tracking key performance indicators (KPIs) and regularly evaluating the impact of the decisions made. Continuous monitoring and adjustments ensure that strategies remain aligned with the evolving business needs and market conditions.