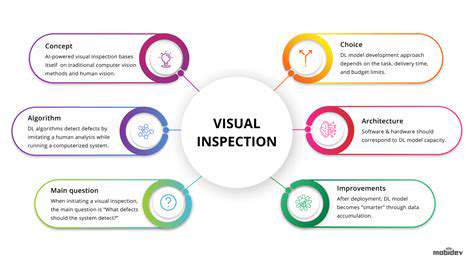

Visual Inspection: A Fundamental Tool

Visual inspection, a seemingly simple process, plays a critical role in various industries and applications. From quality control in manufacturing to medical diagnostics, the ability to identify defects, anomalies, or patterns through observation is invaluable. This method often acts as a first line of defense, quickly identifying potential issues that might otherwise require more complex or time-consuming analysis.

Employing visual inspection techniques requires careful attention to detail and a keen understanding of the specific criteria for the task at hand. Training and experience significantly impact the accuracy and efficiency of this method. Knowing what to look for and recognizing subtle deviations from the norm are key aspects of effective visual inspection.

Methods and Techniques

Various methods and techniques are employed in visual inspection, each tailored to the specific application. High-resolution imaging, magnification tools, and lighting adjustments are often used to enhance visibility and improve the clarity of the inspection process. Careful documentation of findings is essential, including detailed descriptions of observed defects and their location.

For instance, in electronics manufacturing, visual inspection might involve checking for solder bridges or other inconsistencies on printed circuit boards. In automotive manufacturing, visual inspection might focus on component alignment, surface finish, and paint quality.

Importance in Quality Control

Visual inspection is a cornerstone of many quality control processes. By quickly identifying defects or inconsistencies, it helps to prevent the production of faulty products, saving time and resources. Early detection of issues often results in lower repair costs and reduced waste.

Furthermore, visual inspection can contribute to the overall efficiency of production lines by identifying potential problems before they escalate. This proactive approach minimizes downtime and ensures the consistent production of high-quality goods.

Advantages of Visual Inspection

Visual inspection offers several advantages over other inspection methods. Its speed and ease of implementation are notable benefits, allowing for rapid assessment of large quantities of products. The low cost associated with visual inspection makes it an attractive option for many applications.

Additionally, visual inspection often requires minimal specialized equipment, making it accessible to a wider range of personnel. This accessibility allows for broader application and implementation in various settings.

Limitations of Visual Inspection

Despite its advantages, visual inspection does have limitations. Human error, such as fatigue or lack of attention, can impact accuracy. Subtle or complex defects might be missed, requiring supplementary techniques for thorough inspection.

Furthermore, the effectiveness of visual inspection is heavily dependent on the lighting and viewing conditions. Poor lighting or limited magnification can obscure details, leading to inaccuracies.

Training and Expertise

Effective visual inspection hinges on proper training and the development of expertise. Individuals need to be trained on the specific criteria and standards for the task at hand. This training should cover the identification of various defects and anomalies, as well as the proper use of any necessary equipment.

Maintaining consistent standards and expertise through ongoing training and performance evaluations is crucial to ensuring the accuracy and reliability of visual inspection results. Continuous improvement in training and observation techniques directly correlates with better quality control outcomes.