Manufacturing Processes: Optimizing for Sustainability

Material Selection and Sourcing

A crucial aspect of optimizing manufacturing processes for sustainability is the careful selection of materials. Choosing materials with lower environmental impacts throughout their lifecycle, from extraction to disposal, is paramount. This involves considering factors like embodied energy, the amount of energy required to produce the material, and the material's recyclability and reusability. Sustainable sourcing practices are equally important, ensuring that materials are obtained ethically and responsibly, minimizing deforestation, water pollution, and other negative environmental consequences.

Furthermore, exploring alternative materials with reduced environmental footprints, such as bio-based plastics or recycled content, is vital. These choices can significantly reduce the carbon footprint associated with manufacturing and improve the overall sustainability of the final product. Detailed life cycle assessments (LCA) can provide valuable insights into the environmental impact of different materials and guide informed material selection decisions.

Energy Efficiency and Waste Reduction

Minimizing energy consumption during manufacturing processes is essential for reducing greenhouse gas emissions and lowering operational costs. Implementing energy-efficient equipment, optimizing production layouts to minimize material handling, and utilizing renewable energy sources are all effective strategies. This includes exploring and implementing technologies that reduce energy waste and promote greater efficiency in the manufacturing process. A commitment to reducing waste throughout the production process, from raw material use to finished product output, is critical to a sustainable manufacturing process.

Waste reduction strategies, including implementing closed-loop systems for recycling and reuse of byproducts and implementing lean manufacturing principles, contribute significantly to sustainability goals. Waste audits and process improvements can identify areas for optimization and highlight potential opportunities for material recovery and reuse. This not only minimizes environmental impact but also reduces the overall cost of production by minimizing material and energy waste.

Process Optimization and Automation

Optimizing production processes themselves plays a significant role in achieving sustainable manufacturing. Implementing lean manufacturing principles, such as reducing waste and improving efficiency, can significantly impact the environmental footprint. Process optimization techniques, such as value stream mapping, can identify bottlenecks and inefficiencies, leading to improvements in resource utilization and waste reduction. Adopting automation technologies, where appropriate, can further boost efficiency, reduce human error, and minimize energy consumption.

Analyzing production processes to identify areas for improvement, such as reducing energy consumption and minimizing waste generation, is crucial. These improvements can result in a significant reduction in environmental impact, while also improving the bottom line of the manufacturing operation. Furthermore, the use of data-driven analytics and predictive modeling can further refine process optimization efforts, leading to more sustainable and efficient manufacturing operations.

Sustainable Supply Chain Management

A sustainable supply chain is an integral part of sustainable manufacturing. Companies need to consider the environmental and social impacts of their entire supply chain, from raw material sourcing to the final product delivery. This involves working with suppliers who share similar sustainability values and implementing ethical sourcing practices that prevent exploitation and protect human rights. Transparency throughout the supply chain is also crucial, enabling companies to track materials and processes, allowing for greater accountability and control over environmental impacts.

Building strong relationships with suppliers who prioritize sustainability is essential for creating a resilient and responsible supply chain. This includes implementing fair trade principles, ensuring fair labor practices, and promoting environmentally friendly production methods among all supply chain partners. This interconnected approach ensures that the environmental and social responsibility of the entire supply chain is considered and managed effectively, creating a truly sustainable product.

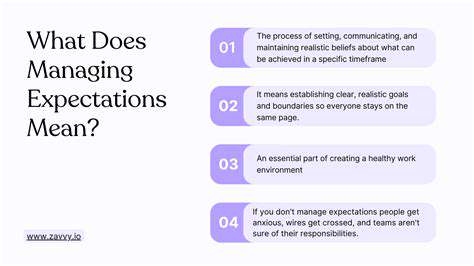

Friction-filled processes, whether in business or personal life, often stem from a lack of clear communication and defined responsibilities. This can lead to misunderstandings, duplicated efforts, and ultimately, a frustrating experience for all parties involved. Poorly designed workflows and systems can also contribute significantly to friction.

The Role of Technology in Eco-Friendly Innovation

The Impact of Technology on Environmental Conservation

Technological advancements have undeniably revolutionized various aspects of our lives, and environmental conservation is no exception. From sophisticated satellite imagery to cutting-edge sensor networks, technology provides powerful tools for monitoring and analyzing environmental changes, enabling us to gain a deeper understanding of complex ecological systems. This knowledge is crucial for developing effective conservation strategies and mitigating the negative impacts of human activities on the planet. Through real-time data analysis, we can identify areas of environmental degradation, track endangered species populations, and even predict future environmental trends. This allows for proactive interventions and resource allocation, ultimately contributing to the preservation of biodiversity and ecosystem health.

Furthermore, technology facilitates the development and implementation of sustainable practices across numerous sectors. For example, advancements in renewable energy technologies, such as solar and wind power, are crucial for reducing our reliance on fossil fuels and mitigating climate change. Smart grids and energy-efficient appliances are also vital tools in reducing energy consumption and promoting sustainable energy practices. Innovative technologies are continually emerging that address various environmental challenges, offering promising solutions for a more sustainable future.

Technological Innovations for Sustainable Practices

The development of eco-friendly technologies is a crucial element in achieving environmental sustainability. This encompasses a wide range of innovative solutions, from designing sustainable transportation systems to creating environmentally responsible manufacturing processes. The integration of technology into various industries is essential for reducing waste, minimizing pollution, and conserving natural resources. For instance, the application of advanced filtration systems in industrial settings can significantly reduce harmful emissions, protecting air and water quality. Furthermore, innovative agricultural technologies can optimize resource utilization, reduce pesticide use, and promote sustainable farming practices, benefiting both the environment and agricultural productivity.

Innovative solutions are being implemented in various sectors to promote sustainable practices. These advancements are driving a paradigm shift towards a more sustainable and resilient future. From smart agriculture practices to the development of biofuels, technology offers a multitude of tools to address the environmental challenges of our time. The application of these technologies is crucial for achieving long-term environmental sustainability and creating a healthier planet for future generations. Sustainable development goals cannot be achieved without leveraging technological advances.

Another critical area is waste management. Technological advancements in recycling and waste disposal systems are essential for reducing landfill waste and promoting resource recovery. These innovations are crucial for minimizing environmental impact and promoting a circular economy. The development of advanced sorting technologies and waste-to-energy systems is transforming the way we manage waste, creating a more sustainable and efficient approach to waste disposal.