Cobalt Mining: A Complex Web of Ethical Concerns

As global reliance on battery-powered technologies grows, cobalt extraction presents increasingly complex moral challenges. The Democratic Republic of Congo (DRC), source of nearly 70% of global cobalt, faces particularly acute ethical dilemmas in its mining sector. Workers frequently encounter hazardous conditions with inadequate safety measures, while reports of child labor continue to surface despite international scrutiny.

Industry analysts note that while some major corporations have implemented supply chain monitoring systems, these efforts often fail to reach artisanal mining operations where the most severe abuses occur. Environmental scientists emphasize that the true cost of cobalt extends far beyond its market price, encompassing both human suffering and ecological damage that may take generations to remediate.

Environmental Impact of Cobalt Extraction

Mining operations disrupt local ecosystems through multiple pathways: chemical runoff contaminates water tables, dust emissions degrade air quality, and land clearance destroys habitats. In the Katanga region, researchers have documented alarming rates of deforestation directly tied to cobalt mining expansion.

The cumulative environmental effects create a paradox where green technology depends on environmentally destructive practices. Hydrologists warn that acid mine drainage from cobalt sites could render agricultural land unusable for decades, while wildlife biologists report declining populations of endemic species in mining-affected areas.

Supply Chain Transparency and Accountability

Recent blockchain initiatives aim to create immutable records of cobalt's journey from mine to manufacturer. However, supply chain experts caution that technology alone cannot solve ethical challenges without corresponding changes in corporate priorities and regulatory frameworks.

Effective oversight requires unprecedented cooperation between governments, corporations, and civil society organizations. Some manufacturers now employ third-party auditors, though critics argue these inspections often provide advance notice, allowing problematic operations to temporarily improve conditions before inspections.

Alternative Solutions and Future Strategies

Materials scientists are exploring multiple approaches to reduce cobalt dependence, including nickel-rich battery chemistries and solid-state alternatives. Meanwhile, urban mining initiatives seek to recover cobalt from recycled electronics, potentially reducing demand for newly mined material.

The most promising solutions combine technological innovation with policy reforms and consumer education. International agreements establishing minimum labor and environmental standards could help level the playing field while protecting vulnerable communities and ecosystems.

Nickel: Environmental Concerns and Sustainable Alternatives

Nickel's Role in Modern Industries

Nickel's unique properties make it indispensable across multiple sectors, from corrosion-resistant alloys to emerging battery technologies. Metallurgists emphasize that no single element currently matches nickel's combination of strength, ductility, and temperature resistance in critical applications like jet engine components and chemical processing equipment.

The metal's importance in stainless steel production alone accounts for nearly 70% of global demand. As electrification accelerates, battery manufacturers increasingly rely on nickel-based cathodes to achieve higher energy densities, creating new sustainability challenges alongside technological advancements.

Environmental Impacts of Nickel Mining

Open-pit nickel mines transform landscapes on massive scales, with some operations covering dozens of square kilometers. Geologists note that the lateritic ores containing most nickel deposits require extensive processing that generates proportionally more waste than other metal ores.

In tropical regions like Indonesia and the Philippines, nickel mining has been linked to deforestation, coastal erosion, and coral reef damage. Environmental engineers warn that inadequate tailings management at some sites creates long-term contamination risks, with heavy metals potentially leaching into groundwater for centuries after mining ceases.

Nickel's Contribution to Air Pollution

Pyrometallurgical nickel processing ranks among the most energy-intensive industrial operations, with some smelters consuming as much electricity as small cities. Fugitive emissions from these facilities often contain nickel carbonyl, a highly toxic compound that requires stringent controls to protect worker health and surrounding communities.

Atmospheric chemists have identified nickel particles as contributors to particulate pollution in industrial regions, with potential links to respiratory and cardiovascular diseases. Some jurisdictions now require real-time emissions monitoring at nickel facilities, though enforcement remains inconsistent globally.

Nickel's Role in Water Contamination

Aquatic systems near nickel operations frequently show elevated metal concentrations, sometimes exceeding regulatory limits by orders of magnitude. Marine biologists have documented bioaccumulation in shellfish and other organisms, raising concerns about ecosystem health and food safety.

In freshwater systems, nickel can disrupt nutrient cycles and alter microbial communities that form the base of aquatic food webs. Some mining companies now employ advanced water treatment systems, but these remain cost-prohibitive for many operations in developing nations.

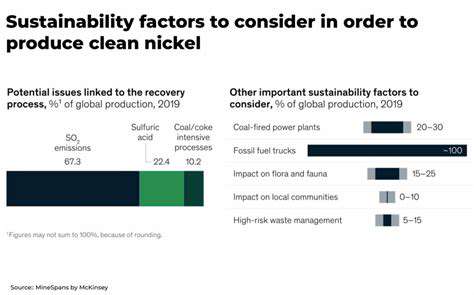

Sustainable Practices in Nickel Production

Hydrometallurgical processing offers potential environmental advantages over traditional smelting, though technical challenges remain. Several major producers now power operations with renewable energy, significantly reducing carbon footprints.

The most progressive operations implement circular economy principles, recovering and reusing process chemicals while extracting valuable byproducts. Industry analysts suggest that combining these approaches with improved mine planning could reduce nickel's environmental impact by 30-40% within a decade.