What's particularly worrying is the massive wave of spent EV batteries heading our way. Current recycling capabilities simply aren't prepared for this onslaught. Without proper systems in place, we're looking at mountains of hazardous waste piling up in landfills or, worse, being processed in unsafe conditions. The time to build proper recycling infrastructure was yesterday - every day we delay increases the environmental burden we'll pass to future generations.

Developing a Robust EV Battery Recycling Infrastructure

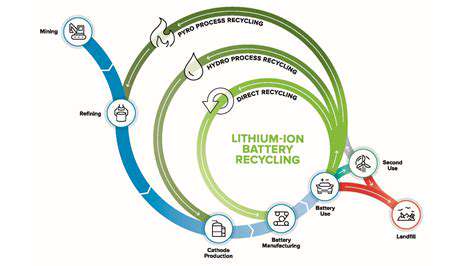

Creating an effective recycling system requires a complete approach that covers every stage of a battery's afterlife. We need innovative technologies that can safely extract valuable materials while minimizing environmental harm. But technology alone isn't enough - we must establish clear guidelines for collection, transportation, and processing. This means setting up specialized facilities and fostering cooperation between manufacturers, recycling companies, and government agencies.

The economic case for investing in recycling is compelling. Proper infrastructure won't just protect the environment - it will create jobs, spur technological advancement, and make the entire EV industry more sustainable. We're talking about developing advanced recovery techniques, building state-of-the-art facilities, and training skilled workers. None of this happens without significant investment and strong regulations to ensure environmental standards are met.

Success will require unprecedented global teamwork. Governments, manufacturers, recyclers, and consumers all have roles to play. This collective effort could transform EV batteries from potential environmental hazards into valuable resources, closing the loop in a true circular economy.

Challenges in Traditional EV Battery Disposal

Material Limitations and Cost

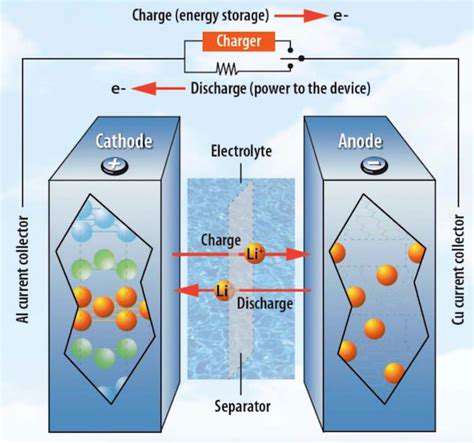

The lithium-ion batteries powering most EVs rely on materials with limited global supply. This creates vulnerabilities in the supply chain and drives up costs, particularly for developing nations trying to adopt EV technology. These price barriers could seriously slow the transition to cleaner transportation, especially in markets where affordability is paramount.

Manufacturing Complexity and Scalability

Building EV batteries isn't like assembling toys - it's an incredibly precise process requiring specialized equipment and expertise. Tiny variations can mean the difference between a reliable battery and a potential safety hazard. Scaling up production to meet growing demand presents enormous challenges, from constructing new facilities to training workforces - all while maintaining strict quality control.

Battery Degradation and Longevity

Every charge cycle and temperature fluctuation takes a toll on battery performance. This gradual decline affects how far EVs can travel on a charge and ultimately determines when batteries need replacement. Improving battery durability isn't just about convenience - it's crucial for maintaining consumer confidence in EV technology over the long term.

Thermal Management Challenges

Batteries are fussy about temperature - too hot or too cold, and performance suffers. Designing systems that keep them in the Goldilocks zone across diverse climates is no simple task. Get this wrong, and you're looking at reduced range, faster aging, or even dangerous situations - all of which undermine the EV ownership experience.

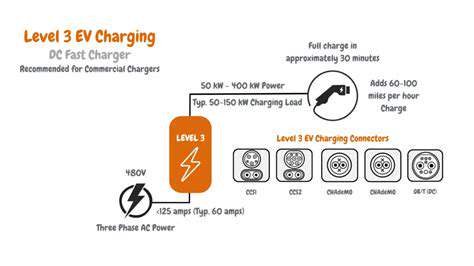

Charging Infrastructure Limitations

Even the best EV is useless if you can't charge it conveniently. The current patchwork of charging stations leaves many potential buyers hesitant, especially those without home charging options. Building out this infrastructure is just as important as improving the vehicles themselves.

Safety Concerns and Risk Mitigation

The rare but terrifying prospect of battery fires gets disproportionate attention, but that doesn't mean safety can be an afterthought. Rigorous testing and fail-safes are non-negotiable - one high-profile incident could set back public acceptance of EVs for years.

Innovative Recycling Technologies and Processes

Innovative Mechanical Processes for Battery Disassembly

Disassembling EV batteries requires precision that only advanced robotics can provide. These high-tech systems carefully separate valuable components while minimizing waste and safety risks - a crucial first step in the recycling chain.

Chemical Leaching for Component Extraction

Specialized chemical solutions can selectively dissolve valuable metals from battery components, but this isn't backyard chemistry. Precise control of temperature and pH ensures maximum yield while preventing environmental contamination - a delicate balancing act requiring expert oversight.

Pyrometallurgical Methods for Metal Recovery

For materials resistant to chemical extraction, high-temperature smelting offers an alternative. While effective, these energy-intensive processes must incorporate strict emission controls to avoid creating new environmental problems while solving old ones.

Hydrometallurgical Methods for Metal Purification

Water-based purification techniques take recovered materials to the next level, removing impurities through precipitation and electro-winning. This multi-stage refinement is essential for producing battery-grade materials from recycled sources.

Advanced Materials Characterization and Analysis

Modern analytical tools like X-ray diffraction give recyclers a molecular-level understanding of battery components. This intelligence allows for process optimization tailored to each batch of materials, maximizing recovery while minimizing waste.

Closed-Loop Systems for Material Recovery and Reuse

The holy grail of recycling turns old batteries into new ones, creating a sustainable loop. This approach reduces mining demand and environmental impact while providing manufacturers with a reliable source of materials - a win-win for business and ecology.

Economic and Regulatory Considerations for Sustainable Recycling

Recycling must make financial sense to thrive long-term. Smart policies can level the playing field against cheaper but less sustainable alternatives, while regulations ensure environmental protections don't get sacrificed for profit.

Economic Incentives and Policy Support for EV Battery Recycling

Economic Incentives for EV Battery Recycling

Financial carrots work better than sticks when building new industries. Tax breaks for recycling investments and rebates for proper battery disposal create positive reinforcement. When recycling becomes the profitable choice, businesses and consumers will flock to it naturally.

Policy Support for EV Battery Recycling

Well-crafted regulations provide the framework for sustainable growth. Mandating recycling, setting material standards, and promoting design-for-recyclability ensure the entire system moves in the right direction - not just the most profitable one.

Public Awareness Campaigns and Education

Knowledge is power when it comes to recycling. Clear communication about proper disposal and the value of recovered materials can transform public behavior, creating grassroots support for recycling initiatives.

International Collaboration and Standardization

Batteries don't respect borders, so neither should our recycling efforts. Global standards and cooperation prevent a patchwork of conflicting regulations that could hinder progress toward a truly circular EV economy.