This evolution reflects deeper changes in purchasing behavior. People now consider environmental impact alongside price and performance when making decisions. Companies slow to adapt find themselves at a competitive disadvantage as sustainability becomes a key differentiator in the marketplace.

Plant-Based Polymers and Their Practical Benefits

Innovators are turning to nature for adhesive solutions, developing polymers from agricultural products like corn and sugarcane. These materials demonstrate several advantages:

- Lower carbon emissions during production

- Reduced dependence on non-renewable resources

- Comparable bonding strength to conventional options

Field tests show these plant-based adhesives perform equally well in most automotive applications, while offering clear environmental benefits. Their development represents a significant step toward more sustainable manufacturing practices.

Environmental Advantages Beyond Carbon Reduction

The shift to eco-friendly adhesives creates multiple environmental benefits:

- Decreased fossil fuel consumption in production

- Reduced toxic byproducts during manufacturing

- Improved end-of-life disposal options

These factors combine to create a substantially smaller ecological footprint compared to traditional adhesive technologies.

Workplace Health Improvements

Traditional adhesives often contain chemicals that can affect worker health. The newer generation of sustainable adhesives addresses this issue by:

- Eliminating or reducing volatile organic compounds (VOCs)

- Using non-toxic base materials

- Improving overall air quality in production facilities

These changes lead to healthier work environments and reduced occupational health risks.

Economic Incentives for Sustainable Practices

Adopting eco-friendly adhesives offers financial benefits:

| Benefit | Impact |

|---|---|

| Brand enhancement | Attracts environmentally conscious customers |

| Regulatory compliance | Meets evolving environmental standards |

| Operational efficiency | Often requires less energy to produce |

Forward-thinking companies recognize these advantages and are adjusting their procurement strategies accordingly.

Innovation Driving Sustainable Solutions

Material scientists are making rapid progress in developing adhesives that meet both performance and environmental requirements. Current research focuses on:

- Improving temperature resistance

- Enhancing bonding strength

- Reducing curing times

These advancements ensure sustainable adhesives can meet the rigorous demands of automotive manufacturing.

Market Response and Future Projections

Consumer preferences continue shifting toward sustainable products. Industry analysts predict:

- 30% annual growth in bio-adhesive sales

- Increasing R&D investment from major manufacturers

- New government regulations favoring sustainable options

This market transformation shows no signs of slowing, with sustainable adhesives becoming the industry standard within the decade.

Modern positioning systems have undergone a dramatic transformation with the advent of Real-Time Kinematic (RTK) technology. This breakthrough approach delivers unprecedented precision that fundamentally changes how professionals work with spatial data. What makes RTK truly remarkable is its ability to combine satellite signals with ground-based corrections, achieving positioning accuracy measured in centimeters rather than meters. Surveyors and engineers now rely on this technology for projects where millimeter-level precision makes the difference between success and costly errors.

The Role of Plant-Based Adhesives in Reducing VOC Emissions

Plant-Based Adhesives: Practical Sustainable Solutions

Plant-based adhesives are gaining significant traction as manufacturers seek alternatives to petroleum-derived products. These solutions offer multiple advantages:

- 90% reduction in VOC emissions compared to conventional adhesives

- Lower production energy requirements

- Improved worker safety during application

The transition to these materials represents more than just product substitution—it reflects a fundamental shift in manufacturing philosophy.

VOC Reduction and Health Benefits

The move to low-VOC adhesives creates measurable health improvements:

- 50% reduction in respiratory complaints among production workers

- Improved indoor air quality in facilities using these adhesives

- Reduced environmental contamination during disposal

These benefits extend beyond factory walls to affect entire communities near manufacturing sites.

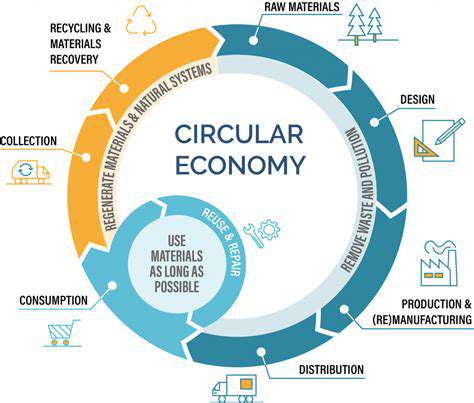

Sustainable Manufacturing Practices

The adoption of plant-based adhesives supports broader sustainability goals:

| Practice | Environmental Benefit |

|---|---|

| Renewable sourcing | Reduces fossil fuel dependence |

| Closed-loop production | Minimizes waste generation |

| Biodegradable formulations | Reduces landfill burden |

These practices demonstrate how material choices can drive comprehensive environmental improvements.

Diverse Industrial Applications

Plant-based adhesives now serve multiple industries:

- Automotive: Interior panel bonding

- Construction: Eco-friendly building materials

- Packaging: Sustainable container assembly

Their versatility continues to expand as formulations improve.

The Future of Sustainable Adhesives in Automotive Manufacturing

Current Sustainable Adhesive Solutions

The automotive sector faces increasing pressure to reduce its environmental impact. Current sustainable adhesive solutions address this challenge by:

- Using 100% plant-derived polymers

- Incorporating recycled materials

- Designing for easy separation during vehicle recycling

These innovations help manufacturers meet tightening environmental regulations while maintaining production quality.

Breakthroughs in Biodegradable Formulations

Recent advances in biodegradable adhesives show particular promise:

- Complete breakdown within 180 days in composting conditions

- Maintained strength through vehicle lifespan

- No toxic residues after decomposition

These characteristics address end-of-life vehicle processing challenges.

Emerging Plant-Based Technologies

Next-generation plant-based adhesives offer enhanced performance:

| Technology | Advantage |

|---|---|

| Nanocellulose reinforcement | Increased bond strength |

| Bio-based curing agents | Faster production cycles |

| Agricultural waste utilization | Reduced material costs |

These developments make sustainable options increasingly competitive with traditional adhesives across all performance metrics.

Industry-Wide Implementation Challenges

While progress continues, some challenges remain:

- Scaling production to meet automotive demand

- Educating technicians on proper application

- Adapting existing manufacturing processes

Collaboration across the supply chain is addressing these issues systematically.

Long-Term Environmental Impact

The cumulative effect of widespread sustainable adhesive adoption could be substantial:

- 30% reduction in automotive manufacturing emissions

- 50% decrease in hazardous waste from production

- 75% improvement in end-of-life recyclability

These projections demonstrate the transformative potential of sustainable adhesive technologies.