Material Selection and Recycling for Reduced Environmental Impact

Material Selection for Sustainability

Choosing the right materials is crucial for minimizing environmental impact throughout a product's lifecycle. A conscious selection process considers the entire material's journey, from extraction and processing to manufacturing, use, and eventual disposal. Prioritizing readily recyclable or biodegradable materials significantly reduces the strain on natural resources and minimizes waste generation. This involves evaluating the environmental footprint of various materials, including their embodied energy, water consumption, and potential toxicity. Sustainable material choices are not just environmentally responsible but also often lead to cost savings and improved product performance over the long term.

Furthermore, understanding the specific properties of each material is essential. Factors like strength, durability, and aesthetic appeal must be balanced against their environmental impact. Substituting traditional materials with more sustainable alternatives, such as bio-based polymers or recycled content, can significantly lower a product's overall environmental footprint. This meticulous consideration of material properties and their impact on the environment is a cornerstone of green manufacturing principles.

Recycling Strategies for Material Recovery

Effective recycling programs are vital to recovering valuable materials and preventing them from ending up in landfills. Designing products with recyclability in mind is paramount. This involves considering material compatibility during the manufacturing process to ensure that components can be separated and processed efficiently. Clear labeling and standardized sorting systems are essential for successful material recovery. Implementing robust collection and sorting infrastructure, including community-based programs and advanced sorting technologies, is crucial for maximizing recycling rates.

Implementing closed-loop recycling systems, where recovered materials are reused in the production of new products, further minimizes environmental impact. This creates a circular economy, reducing the demand for virgin materials and minimizing waste. Partnerships with recycling facilities and stakeholders are key to ensuring the successful implementation and optimization of recycling strategies. Continuous monitoring and evaluation of these programs are essential to identify areas for improvement and ensure effective material recovery.

Design for Disassembly and Material Recovery

Designing products for easy disassembly and material recovery is a crucial aspect of green manufacturing. This approach focuses on simplifying the product's structure to facilitate the separation of different materials. Using standardized components and modular designs allows for more efficient disassembly and recycling. This also simplifies the process of recovering valuable materials, minimizing the energy required for processing, and reducing the risk of contamination during the recycling process. By optimizing the design for disassembly, manufacturers can significantly reduce the environmental impact of their products.

Clearly defining material boundaries and developing appropriate protocols for dismantling products are necessary steps in ensuring proper material separation. This includes the use of specialized tools and techniques to avoid damaging or contaminating materials. By incorporating these principles into product design, manufacturers can significantly enhance the recyclability of their products and contribute to a more sustainable future.

Promoting Material Reuse and Upcycling

Moving beyond simple recycling, strategies for reusing and upcycling materials offer significant environmental advantages. Reusing materials in their original form or adapting them for new applications reduces the need for extracting virgin resources. Upcycling involves transforming waste materials into higher-value products, adding aesthetic and functional enhancements. This approach transforms waste into valuable resources, creating new economic opportunities and minimizing waste generation. Implementing reuse and upcycling initiatives within manufacturing processes can create a more circular economy, reducing material consumption and promoting sustainability.

Collaborating with designers, artists, and entrepreneurs to explore innovative reuse and upcycling applications can lead to novel product designs and business models. These creative solutions can transform discarded materials into valuable assets, reducing landfill waste and minimizing the environmental impact of manufacturing processes. Promoting public awareness and education about reuse and upcycling practices can further encourage a shift towards more sustainable consumption patterns.

Energy Efficiency in Manufacturing Processes

Improving Energy Efficiency Through Process Optimization

Energy efficiency in manufacturing processes is paramount for sustainable operations in the auto sector. Implementing lean manufacturing principles, such as reducing waste and optimizing workflows, directly impacts energy consumption. For instance, streamlining assembly lines, minimizing material handling, and utilizing automated guided vehicles (AGVs) can significantly decrease the energy required for production. These optimizations not only lower operational costs but also reduce the environmental footprint, aligning with the growing demand for green manufacturing practices within the automotive industry.

Process optimization also extends to the selection of equipment. Employing high-efficiency motors, pumps, and compressors can drastically reduce energy consumption during various stages of production. Implementing predictive maintenance programs can further enhance efficiency by anticipating equipment failures and preventing costly downtime. This proactive approach allows for timely repairs and replacements, minimizing energy losses associated with unexpected shutdowns and maximizing the operational life of machinery.

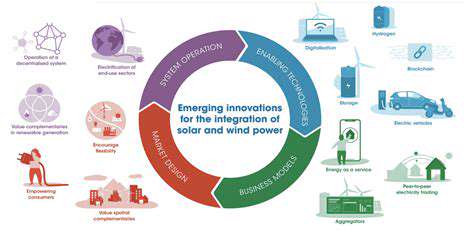

Implementing Renewable Energy Sources and Smart Technologies

Integrating renewable energy sources into manufacturing facilities is a critical step towards achieving greater energy efficiency. Solar panels, wind turbines, and geothermal energy systems can provide a significant portion of the energy required for production, reducing reliance on fossil fuels and lowering carbon emissions. Utilizing these sustainable energy sources not only enhances the environmental performance of the manufacturing process but also positions the company for long-term cost savings by reducing energy bills.

Furthermore, implementing smart technologies plays a vital role in optimizing energy consumption. Smart sensors and data analytics can monitor energy usage in real-time, enabling proactive adjustments to processes and identifying areas for improvement. This data-driven approach allows for the development of targeted strategies to reduce energy consumption, ultimately improving overall energy efficiency throughout the manufacturing facility.

Implementing energy-efficient lighting systems, such as LED lighting, is another crucial aspect of the transition towards green manufacturing. These systems significantly reduce energy consumption compared to traditional lighting methods, resulting in substantial cost savings and decreased carbon emissions. Moreover, smart lighting controls can further optimize energy use by automatically adjusting lighting levels based on occupancy and ambient light conditions.

The integration of energy management systems (EMS) can provide a comprehensive view of energy consumption across the entire manufacturing facility. These systems allow for real-time monitoring, analysis, and control of energy usage, enabling the identification of inefficiencies and the implementation of targeted measures to improve energy efficiency.

Implementing advanced control systems for heating, ventilation, and air conditioning (HVAC) is also vital for optimizing energy usage in manufacturing facilities. These systems can adjust temperatures and airflow based on real-time needs, minimizing energy waste and reducing the overall environmental impact.

Implementing these strategies is not just an environmental responsibility; it's a key component of a successful and sustainable business model in the competitive automotive sector.

Sustainable Supply Chain Management

Optimizing Resource Allocation for Sustainability

Sustainable supply chain management hinges on optimizing resource allocation to minimize environmental impact and maximize resource efficiency. This involves a careful analysis of the entire supply chain, from raw material sourcing to final product delivery, to identify areas where resources are being wasted or consumed inefficiently. Implementing strategies like closed-loop systems, where materials are reused or recycled, is crucial for achieving this goal. Such systems not only reduce waste but also lower costs and enhance the company's overall environmental performance. By prioritizing resource conservation, businesses can contribute to a more sustainable future while simultaneously improving their bottom line.

Furthermore, sustainable supply chain management necessitates a thorough understanding of the entire lifecycle of products, from cradle to grave. This includes evaluating the environmental impacts associated with each stage, from material extraction to manufacturing, transportation, and eventual disposal. Understanding these impacts allows businesses to identify areas for improvement and implement changes that minimize their environmental footprint. This comprehensive approach ensures that environmental considerations are integrated throughout the entire value chain, from suppliers to customers.

Building Transparency and Collaboration for Ethical Practices

Transparency and collaboration are essential components of a sustainable supply chain. Businesses need to be open about their sourcing practices, environmental performance, and social responsibility efforts. This transparency allows stakeholders, including consumers and investors, to assess the sustainability of the supply chain and hold businesses accountable. Open communication and collaboration with suppliers, manufacturers, and other partners are vital to identify and address potential ethical concerns and environmental risks throughout the chain.

Building trust and fostering ethical relationships with suppliers is paramount for long-term success. It requires a commitment to fair labor practices, ethical sourcing, and respect for human rights. Companies must actively engage with their suppliers to ensure that they adhere to high ethical standards and environmental regulations. This collaborative approach encourages responsible sourcing and prevents the exploitation of workers or the depletion of natural resources. Implementing robust ethical and environmental safeguards is crucial for building a sustainable and resilient supply chain.

Establishing clear communication channels and fostering a culture of accountability are critical in achieving these goals. This promotes a shared understanding of sustainability targets and encourages continuous improvement throughout the supply chain. By working together, businesses can minimize risks, promote ethical practices, and ultimately contribute to a more sustainable global economy.

Establishing robust ethical sourcing policies, including fair compensation for workers and safe working conditions, is critical to mitigate social risks. This approach ensures that the entire supply chain operates with integrity. Encouraging collaboration and knowledge sharing between businesses and their suppliers can enhance the effectiveness of sustainability initiatives.

Promoting Collaboration and Innovation

Fostering a Culture of Open Communication

Cultivating a workplace environment that encourages open communication is paramount to successful collaboration. Employees must feel comfortable sharing ideas, concerns, and feedback without fear of retribution or judgment. This includes establishing clear communication channels and actively listening to diverse perspectives. Creating safe spaces for dialogue and providing opportunities for employees to connect on a personal level can significantly enhance collaboration and innovation.

Regular team meetings, brainstorming sessions, and informal interactions can foster a sense of community and shared purpose. Furthermore, implementing tools and technologies that facilitate seamless communication, such as project management software and instant messaging platforms, can streamline workflows and improve efficiency.

Establishing Clear Roles and Responsibilities

Defining clear roles and responsibilities for each team member is essential for effective collaboration. This ensures that everyone understands their specific contribution to the overall project or goal. Ambiguity regarding tasks and expectations can lead to conflict, wasted effort, and ultimately, hinder innovation.

Clearly outlined procedures and protocols contribute to a more structured and efficient workflow. This clarity prevents duplication of efforts and allows team members to focus their energy on tasks they are best equipped to handle. Well-defined roles and responsibilities create a shared understanding of the project's objectives and ensure that all team members are working towards the same goals.

Encouraging Cross-Functional Collaboration

Breaking down departmental silos and encouraging cross-functional collaboration is crucial for innovation. Bringing together individuals from different backgrounds and expertise allows for the exchange of diverse perspectives, leading to more creative and effective solutions.

This cross-pollination of ideas can spark new insights and approaches to problem-solving. By fostering an environment where individuals from various departments can collaborate freely, organizations can unlock the full potential of their workforce and drive significant innovation.

Providing Resources and Support

Providing employees with the necessary resources and support is essential for enabling them to collaborate effectively. This includes access to relevant technology, training opportunities, and mentorship programs. Access to tools and resources empowers employees to contribute meaningfully to projects and fosters a collaborative spirit.

Dedicated support staff, such as project managers or facilitators, can play a critical role in guiding teams and resolving conflicts that may arise. Providing ongoing training and development opportunities ensures that employees remain equipped with the necessary skills to participate in collaborative projects effectively. This supportive environment is critical for both innovation and overall team success.

Recognizing and Rewarding Collaboration

Recognizing and rewarding collaborative efforts is vital for reinforcing the importance of teamwork and fostering a culture of innovation. Implementing recognition programs that specifically acknowledge collaborative achievements can motivate team members to work together effectively.

Publicly acknowledging and celebrating successful collaborative projects sends a powerful message about the value of teamwork and inspires others to emulate these positive behaviors. Incentivizing collaboration can also encourage employees to actively seek out opportunities to work together and share knowledge and ideas, ultimately leading to breakthroughs and new innovations.

Measuring and Evaluating Collaboration Initiatives

Implementing metrics to measure and evaluate the success of collaboration initiatives is crucial for continuous improvement. This includes tracking key performance indicators (KPIs) such as project completion rates, communication frequency, and the number of innovative ideas generated. This data will provide insights into what's working well and where improvements are needed.

Regularly assessing the effectiveness of collaboration strategies allows organizations to fine-tune their approach and optimize their processes for maximum impact. By analyzing the data generated from these initiatives, organizations can identify areas for improvement in communication, resource allocation, and team dynamics. This ongoing evaluation process ensures that collaboration initiatives remain relevant and effective in driving innovation.