Advanced Polymer Technology and Nanotechnology

Polymer Composites for Enhanced Durability

Advanced polymer composites, incorporating nanomaterials, are revolutionizing automotive coatings. These composites offer enhanced durability and resistance to environmental factors like UV radiation, moisture, and abrasion. The incorporation of specific nanofillers, such as carbon nanotubes or graphene, significantly strengthens the polymer matrix, leading to a more resilient and long-lasting coating. This superior performance translates to extended lifespan for vehicles, reducing the need for frequent repainting and maintenance, which ultimately contributes to a more sustainable approach to automotive manufacturing.

The precise tailoring of these composites allows for optimized properties, enabling coatings to withstand harsh weather conditions and extreme temperature fluctuations. This superior performance is crucial for the automotive industry, ensuring the longevity of vehicles in diverse climates and usage scenarios. The reduced need for repairs and replacements directly contributes to a lower environmental footprint compared to traditional coatings.

Nanotechnology for Improved Scratch Resistance

Nanotechnology plays a vital role in creating automotive coatings with exceptional scratch resistance. By incorporating nanoparticles into the polymer matrix, we can create a significantly harder and more abrasion-resistant surface. These nanoparticles act as reinforcing agents, creating a dense and robust protective layer that effectively deflects scratches and other forms of surface damage. This advanced scratch resistance translates to a higher perceived value and longevity of the vehicle, appealing to consumers seeking durable and long-lasting automotive finishes.

The inclusion of nanoscale fillers and additives allows for the development of coatings that are not only resistant to scratches but also maintain a visually appealing, smooth surface. This crucial combination of performance and aesthetics is essential for the automotive industry, ensuring that vehicles retain their showroom-quality appearance over time. Reducing the frequency of repairs and replacements contributes significantly to sustainable manufacturing practices.

Sustainable Sourcing of Polymer Materials

A key aspect of sustainable coatings involves the use of polymers derived from renewable sources. Bio-based polymers, produced from plant-derived resources, offer a promising alternative to traditional petroleum-based polymers. These sustainable materials reduce reliance on finite resources, aligning with environmental responsibility and minimizing the carbon footprint associated with manufacturing. The shift toward bio-based polymers represents a significant step toward creating more environmentally friendly automotive coatings, impacting the entire lifecycle of the vehicle.

Self-Healing Properties in Polymer Coatings

Self-healing properties are being incorporated into advanced polymer coatings using nanotechnology. These coatings contain microcapsules filled with healing agents. When damaged, the microcapsules rupture, releasing the healing agent, which fills the scratch or defect, effectively repairing the damage. This innovative approach minimizes the need for costly repairs and replacements, extending the lifespan of the coating and the vehicle. This self-healing characteristic is a significant advancement, contributing substantially to the longevity and reduced environmental impact of automotive finishes.

Enhanced UV Resistance and Color Retention

Advanced polymer technologies are enabling the development of coatings with exceptional UV resistance, crucial for preserving the color and appearance of vehicles. Nanomaterials, such as titanium dioxide nanoparticles, can absorb UV radiation, preventing color fading and degradation. This enhanced UV protection ensures that vehicles maintain their vibrant colors over time, enhancing their aesthetic appeal and perceived value. The use of these nanomaterials reduces the need for frequent repainting, contributing to a more sustainable and cost-effective approach in the automotive sector.

The Future of Sustainable Coatings in the Automotive Sector

The Growing Demand for Eco-Friendly Options

The global demand for sustainable products is rapidly increasing, and coatings are no exception. Consumers are becoming increasingly aware of the environmental impact of their choices, pushing manufacturers to develop more eco-friendly alternatives to traditional coatings. This growing demand is driving innovation in the coatings industry, leading to a surge in research and development of sustainable materials and processes.

This shift towards sustainability is not just a trend; it's a fundamental change in consumer behavior. Companies that fail to adapt to this evolving landscape risk losing market share to competitors offering greener solutions.

Bio-Based and Renewable Resources

One key area of focus in the future of sustainable coatings is the use of bio-based and renewable resources. These materials are derived from plant-based sources, reducing reliance on fossil fuels and minimizing the environmental footprint of the coating process. This approach not only reduces the carbon footprint but also promotes a more circular economy.

The development of bio-based polymers and resins offers a promising avenue for creating coatings with superior performance while minimizing environmental damage. These materials can be fully or partially derived from sustainable sources, such as agricultural waste or algae.

Advanced Formulation Technologies

Innovation in coating formulation is critical to achieving improved performance and sustainability. Researchers are exploring new technologies to reduce the use of volatile organic compounds (VOCs), which are harmful air pollutants. These advancements aim to create coatings that are both environmentally friendly and maintain high quality and durability.

Advanced formulation strategies are enabling the creation of coatings with enhanced properties, such as improved adhesion, flexibility, and resistance to harsh environments. These advancements are key to meeting the evolving needs of various industries.

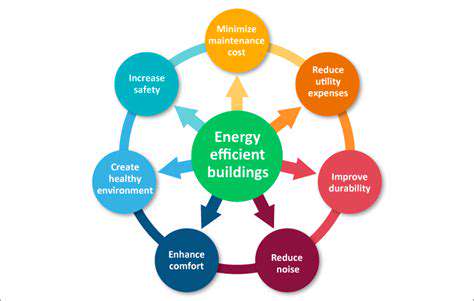

Improved Durability and Performance

Sustainable coatings must not compromise on performance. Coatings are crucial for protecting surfaces from damage and degradation, and this critical function must be maintained as the industry shifts to more sustainable practices. Researchers are actively developing sustainable coatings that offer comparable or superior performance to their traditional counterparts.

The development of coatings with improved durability and performance is crucial for widespread adoption. Coatings need to effectively protect surfaces over their lifespan without compromising on environmental considerations. This is essential for industries like construction, automotive, and aerospace.

Reduced VOC Emissions

The reduction of volatile organic compounds (VOCs) is a significant concern in the coatings industry. VOCs contribute to air pollution and pose health risks to workers and the general public. Reducing VOC emissions is a crucial step towards creating truly sustainable coatings.

Minimizing or eliminating VOCs is paramount to environmental protection and public health. Innovative technologies are being explored to replace traditional solvents with more sustainable alternatives, such as water-based systems and bio-based solvents.

Circular Economy Principles

The future of sustainable coatings is intricately linked to the principles of a circular economy. This approach emphasizes the reuse and recycling of materials, reducing waste and promoting resource efficiency throughout the entire lifecycle of a coating product. By implementing circular economy principles, the industry can minimize waste and maximize the use of recycled materials.

Adopting circular economy principles is essential to achieving true sustainability in the coatings industry. This involves designing coatings for easy disassembly, enabling the reuse or recycling of components after the product's lifespan.

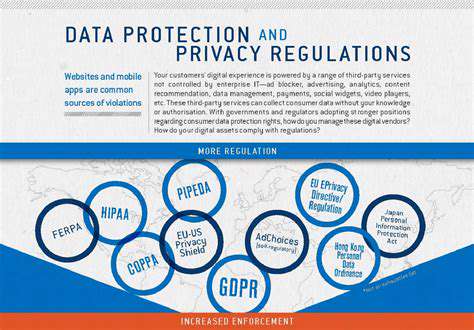

Government Regulations and Incentives

Government regulations and policies play a vital role in shaping the future of sustainable coatings. Regulations that incentivize the use of sustainable materials and limit the release of harmful pollutants can encourage innovation and accelerate the transition to greener options. Government support for research and development in this area is also critical.

Government regulations and incentives are critical for driving the adoption of sustainable coatings and influencing industrial practices. This encouragement can lead to significant progress in the coatings industry, creating a positive impact on the environment and the economy.