The transition toward sustainable materials in the automotive sector is driven by a global commitment to environmental protection and the growing demand for eco-friendly vehicles. Innovative materials like bio-based plastics, composites, and recycled metals offer promising alternatives to traditional materials, significantly reducing the environmental impact of vehicle production and disposal. Bio-based plastics, derived from renewable sources like plants, offer a sustainable alternative to petroleum-based plastics, reducing reliance on finite resources and lowering carbon emissions throughout the manufacturing process.

Composites, a combination of different materials, are increasingly used in vehicle components, providing a high strength-to-weight ratio. This characteristic allows for lighter vehicles, improving fuel efficiency and reducing emissions. Furthermore, the use of recycled metals, including aluminum and steel, reduces the need for new raw material extraction, minimizing environmental damage and promoting circular economy principles. These sustainable alternatives are crucial in the pursuit of a more environmentally friendly automotive sector and are paving the way for a future where vehicle production aligns with environmental sustainability.

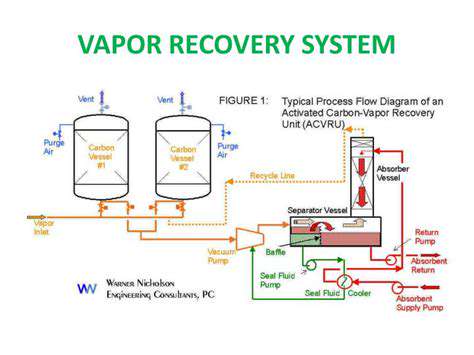

The development and implementation of advanced recycling technologies are also critical in ensuring the lifecycle of these materials is as sustainable as possible. These recycling processes will allow for the recovery of valuable materials from end-of-life vehicles, creating a closed-loop system that minimizes waste and maximizes resource utilization. This transition toward sustainable materials is not just about reducing environmental impact but also about fostering a more resilient and responsible automotive industry.

The transition to sustainable materials also presents economic opportunities for businesses and governments. Investments in research and development, coupled with supportive policies, can drive innovation and create new jobs in the sustainable automotive sector. This transition is not simply a response to environmental concerns but also represents a significant economic opportunity for the future.

Exploring Bio-Based Plastics for a Greener Future

Exploring the Potential of Bio-Based Plastics

Bio-based plastics are gaining significant attention as a potential solution to the environmental concerns associated with traditional petroleum-based plastics. These materials, derived from renewable resources like corn starch, sugarcane, and other plant matter, offer the possibility of reducing reliance on fossil fuels and minimizing the environmental impact of plastic waste. This shift towards bio-based alternatives is crucial for mitigating the global plastic pollution crisis.

The production of bio-based plastics often involves the use of fermentation processes, which can potentially reduce greenhouse gas emissions compared to conventional petroleum-based plastic production. These processes also hold the promise of utilizing agricultural waste products, thereby reducing waste and promoting sustainable agricultural practices.

Challenges and Considerations in Bio-Based Plastic Production

Despite the promising potential of bio-based plastics, significant challenges remain. One key hurdle is the cost-effectiveness of production. Currently, bio-based plastics often come with a higher price tag than their petroleum-based counterparts, which can hinder widespread adoption. This cost barrier needs to be addressed through innovation and improved efficiency.

Another critical aspect is the performance characteristics of bio-based plastics. Some bio-based materials may not exhibit the same strength, durability, or other desirable properties as traditional plastics. Researchers are actively working to improve the performance of these materials to meet the demands of various applications.

Environmental Impact and Sustainability

The environmental impact of bio-based plastics is a complex issue, extending beyond the production process. The sustainability of these materials hinges on the entire lifecycle, from raw material sourcing to end-of-life management. Careful consideration must be given to the environmental footprint of cultivating the feedstock, and the proper disposal or recycling methods for bio-based plastics need to be developed and implemented.

Ultimately, true sustainability requires a holistic approach, examining the entire life cycle of bio-based plastics, from raw material production to waste management. Assessing the overall environmental impact, including carbon footprint and resource consumption, is paramount in evaluating the true sustainability of these materials.

Applications and Future Directions

Bio-based plastics have diverse potential applications in various sectors, including packaging, textiles, and even medical devices. The development of new bio-based materials with enhanced properties will open doors to even more innovative solutions. For example, researchers are exploring the potential of incorporating bio-based components into composite materials to enhance their strength and durability.

Looking ahead, further research and development are crucial to unlock the full potential of bio-based plastics. This includes the exploration of new feedstocks, the optimization of production methods, and the development of innovative applications. The future of bio-based plastics depends on continued innovation and collaboration among researchers, industry leaders, and policymakers.

The Rise of Recycled Materials and Composites

Recycled Plastics: A Growing Resource

The automotive industry is increasingly recognizing the importance of incorporating recycled plastics into its manufacturing processes. This shift is driven by a combination of factors, including a growing awareness of the environmental impact of traditional petroleum-based plastics and the increasing availability of high-quality recycled materials. Recycled plastics offer a compelling alternative, reducing reliance on virgin resources and minimizing waste streams. This approach not only promotes sustainability but also presents significant cost savings in the long run.

The development of advanced recycling technologies, such as mechanical and chemical recycling, is crucial to achieving high-quality recycled plastics suitable for automotive applications. These processes allow for the extraction of valuable polymers from waste materials, transforming them into usable components for car parts, thereby reducing the overall environmental footprint of the industry.

Composites: Engineered for Performance and Sustainability

Composites, often incorporating recycled fibers and resins, are gaining traction in the automotive sector. Their unique properties, including high strength-to-weight ratios and the potential for customization, make them attractive alternatives to traditional materials. This innovative approach to material science allows for the creation of lightweight components, which in turn improves fuel efficiency and reduces emissions.

The integration of recycled materials into composite formulations is a key aspect of this trend. Using recycled fibers, such as those derived from post-consumer plastic bottles or agricultural byproducts, reduces the environmental impact and promotes a circular economy model.

Sustainable Sourcing of Raw Materials

A crucial aspect of the rise of recycled materials and composites is the commitment to sustainable sourcing of raw materials. This includes partnering with suppliers who prioritize responsible forestry practices, ethical sourcing of minerals, and the use of renewable energy in their operations. Such collaborations ensure a transparent and environmentally conscious supply chain.

Lightweighting: A Key Benefit of Recycled Materials

One of the primary advantages of employing recycled materials and composites in automotive manufacturing is the potential for lightweighting. By replacing heavier traditional materials with lighter alternatives, manufacturers can significantly improve fuel efficiency and reduce emissions. This translates to substantial environmental benefits and economic advantages for the industry.

Cost-Effectiveness and Economic Incentives

The transition to recycled materials and composites is not solely driven by environmental concerns. The cost-effectiveness of these materials, coupled with potential government incentives and tax credits for sustainable practices, is also a strong motivator for automotive manufacturers. This combination of economic benefits and environmental responsibility is driving significant investment in research and development in this area.

Technological Advancements in Recycling

Continuous advancements in recycling technologies are enabling the production of higher-quality recycled materials. These advancements improve the purity and consistency of recycled materials, making them suitable for a wider range of automotive applications. This progress is crucial for the widespread adoption of recycled materials in the automotive industry.

Design for Disassembly and Recycling

A holistic approach to sustainability in automotive manufacturing involves designing vehicles for easy disassembly and recycling. This means incorporating modular components and using compatible materials that allow for efficient separation and recovery of valuable resources at the end of a vehicle's life cycle. This design philosophy contributes to a more circular economy for the automotive industry.

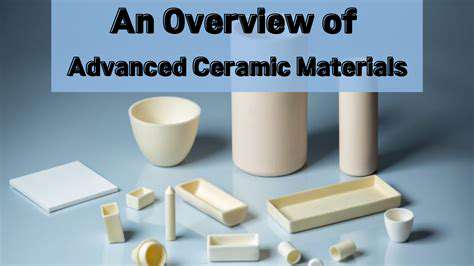

Advanced Materials: Beyond Plastic and Metal

Beyond the Limitations of Conventional Plastics

Conventional plastics, while ubiquitous in modern life, suffer from several significant limitations. Their reliance on fossil fuels for production contributes to environmental concerns, and their inherent properties, such as low biodegradability and durability issues, often lead to pollution and waste management problems. Exploring innovative materials offers a crucial path towards sustainable alternatives.

The search for superior substitutes is driven by the urgent need to reduce our environmental footprint and develop materials with enhanced performance characteristics. This pursuit necessitates a shift towards more sustainable and efficient production processes.

Bio-Based Polymers: A Sustainable Solution

Bio-based polymers, derived from renewable resources like plant starches or agricultural waste, represent a promising avenue for sustainable plastics. These materials offer a pathway to reduce reliance on fossil fuels and minimize the environmental impact associated with conventional plastics production. The development of bio-based polymers is not just about creating alternatives, but about creating a more circular economy.

Advanced Composites: Enhanced Properties

Advanced composites, often incorporating carbon fiber, graphene, or other high-performance materials, offer enhanced mechanical strength, lightweight properties, and superior thermal stability compared to traditional plastics. These materials are finding increasing applications in aerospace, automotive, and construction industries.

Smart Materials: Responsive Properties

Smart materials possess unique properties that enable them to respond to external stimuli, such as temperature changes, light, or electric fields. These materials can be tailored to specific applications, offering possibilities for innovative designs and functionalities in areas like self-healing coatings and actuators.

Their ability to adapt to changing conditions opens up exciting possibilities for advanced engineering and design.

Self-Healing Materials: Repairing Damage

Self-healing materials are a game-changer in terms of durability and longevity. These materials possess the remarkable ability to repair damage on their own, extending their lifespan and reducing the need for frequent replacements. This innovative property presents significant potential for various applications, from automotive components to construction materials.

Conductive Polymers: Electrical Applications

Conductive polymers exhibit remarkable electrical conductivity, making them ideal for applications in electronics and energy storage. Their unique combination of mechanical flexibility and electrical properties allows for the development of novel devices and systems. These materials could revolutionize the field of flexible electronics.

Sustainable Manufacturing Processes: Eco-Friendly Production

Moving beyond the materials themselves, sustainable manufacturing processes are crucial for minimizing the environmental impact of advanced materials. This involves optimizing production methods to reduce energy consumption, minimize waste generation, and utilize recycled materials whenever possible. Sustainable manufacturing is essential for creating a truly circular economy in the materials industry. This approach will be vital for long-term success in the development and adoption of advanced materials.