Understanding VOCs and Waterborne Paints

Volatile Organic Compounds (VOCs) are emitted as gases from certain products, including traditional paint formulations. These gases can contribute to air pollution and have been linked to various health issues. Waterborne paints, on the other hand, utilize water as a primary solvent, significantly reducing the release of VOCs into the atmosphere. This shift towards water-based paints is a crucial step in minimizing environmental impact and promoting healthier indoor air quality. The reduction in VOC emissions is a key benefit for both human health and the environment.

Environmental Benefits of Waterborne Paints

The environmental advantages of waterborne paints extend beyond reduced VOC emissions. Water-based formulations typically require less energy to produce and process, leading to lower carbon footprints compared to solvent-based paints. Reduced energy consumption translates into decreased greenhouse gas emissions, contributing to a more sustainable approach to manufacturing and use. Furthermore, the water-based nature of these paints often allows for easier disposal and recycling, minimizing waste and promoting resource conservation.

Health Impacts of VOCs in Traditional Paints

Prolonged exposure to VOCs from traditional paints can have adverse effects on human health. Symptoms can range from eye, nose, and throat irritation to more serious respiratory problems. Children and individuals with pre-existing respiratory conditions are particularly vulnerable to the health risks associated with VOC exposure. The shift towards waterborne paints significantly reduces these health risks, creating a healthier indoor environment for all occupants.

Technological Advancements in Waterborne Paint Production

Modern advancements in chemistry and manufacturing techniques have led to significant improvements in the performance and durability of waterborne paints. These formulations now offer comparable or superior properties to traditional solvent-based paints, addressing concerns about longevity, coverage, and aesthetic appeal. Formulators are continually striving for optimal performance while maintaining the environmentally friendly characteristics of water-based paints, making them a more attractive and versatile option for a wide range of applications.

Cost-Effectiveness and Accessibility of Waterborne Paints

Despite initial concerns about potential cost differences, waterborne paints have become increasingly accessible and competitive in price. The reduced manufacturing costs associated with water-based formulations, coupled with decreasing raw material prices, often make them a cost-effective choice. The growing consumer demand for sustainable products has also encouraged manufacturers to further refine their production processes, making waterborne paints more affordable and readily available for diverse consumer needs.

The Future of Sustainable Paint Technology

The future of paint technology is undoubtedly leaning towards even more sustainable solutions. Research and development are focused on innovative formulations that further minimize environmental impact. Bio-based paints, derived from renewable resources, are emerging as a promising alternative, potentially minimizing the reliance on fossil fuels and offering a truly eco-friendly option. The industry is committed to continuing to develop and improve upon existing sustainable practices, ensuring that future generations can enjoy the benefits of healthy and environmentally sound paint technology.

Advanced Coatings with Enhanced Durability and Performance

Advanced Coatings for Enhanced Durability

Advanced coatings are revolutionizing various industries by significantly enhancing the durability and performance of materials. These coatings, often incorporating nanomaterials or specialized polymers, provide superior resistance to corrosion, wear, and environmental degradation. This improved resilience translates to longer lifespan and reduced maintenance costs for the coated items. The development of these coatings is a significant leap forward in material science and engineering.

Nanomaterial Integration for Superior Properties

A key component of advanced coatings is the integration of nanomaterials. These materials, with their unique nanoscale structures, offer exceptional properties like enhanced strength, hardness, and chemical resistance. Nanoparticles, when incorporated into coatings, can significantly improve their mechanical and barrier properties. For example, the incorporation of titanium dioxide nanoparticles can lead to coatings with significantly improved UV resistance.

Improved Corrosion Resistance in Harsh Environments

Corrosion is a significant concern in many industrial applications, leading to costly repairs and downtime. Advanced coatings, specifically formulated with corrosion-resistant components, provide a protective barrier against aggressive chemicals and environmental factors. These coatings effectively shield the underlying material, preventing premature degradation and extending its service life in challenging conditions. This is particularly crucial in marine environments, industrial facilities, and other settings with high exposure to corrosive agents.

Enhanced Wear Resistance for Increased Lifespan

Wear resistance is another critical factor in the performance of many components. Advanced coatings are engineered to provide superior abrasion resistance, mitigating the effects of friction and wear. This translates directly to extended component lifespan and reduced replacement needs. The application of such coatings can dramatically reduce the frequency of maintenance and repairs. This is particularly valuable in machinery, tools, and other components subjected to high wear and tear.

Thermal Management and Heat Resistance

Many applications require materials to withstand extreme temperatures. Advanced coatings play a crucial role in thermal management by providing excellent heat resistance and insulation. These coatings can effectively prevent heat transfer, protecting the underlying material from thermal degradation and ensuring optimal performance in high-temperature environments. High-temperature coatings are essential in aerospace, automotive, and industrial applications.

Cost-Effectiveness and Sustainability Considerations

While advanced coatings offer significant performance advantages, cost-effectiveness is also a crucial consideration. Recent advancements in coating technologies have led to more cost-effective solutions without compromising performance. The long-term benefits of reduced maintenance and extended lifespan often outweigh the initial investment. Moreover, sustainable materials and manufacturing processes are increasingly important in the development of advanced coatings, ensuring environmentally friendly solutions for the future.

Lithium, a key component in EV batteries, is a crucial raw material. Its extraction, however, often involves environmentally damaging practices, such as large-scale water consumption and potential contamination of local water sources. Finding sustainable and responsible lithium extraction methods is paramount for the long-term viability of the EV industry and its environmental impact.

Exploring Bio-Based and Recycled Materials in Paint Formulations

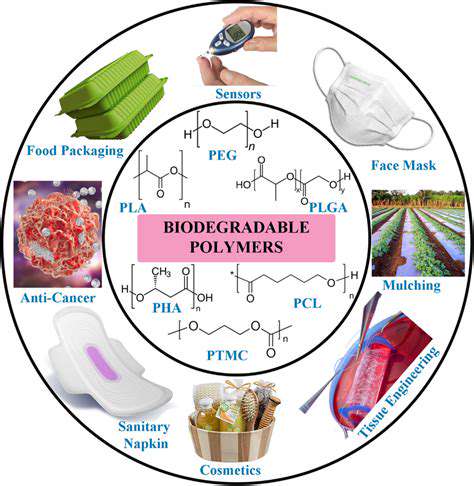

Exploring the Potential of Bio-Based Materials

Bio-based materials offer a compelling alternative to traditional petroleum-derived plastics, promising a more sustainable future. These materials, derived from renewable resources like plants and agricultural byproducts, significantly reduce reliance on finite fossil fuels. Their inherent biodegradability reduces the environmental burden of waste, a crucial factor in mitigating the impacts of plastic pollution. Furthermore, the production of bio-based materials can often be less energy-intensive than the production of conventional plastics.

The Role of Recycled Materials in Sustainable Manufacturing

Recycled materials play a vital role in minimizing environmental impact. The process of recycling conserves natural resources, reducing the need for raw material extraction. This conservation effort is crucial in maintaining ecological balance, and it also significantly decreases the energy consumption associated with resource extraction and processing. Recycled materials also often have a lower carbon footprint compared to virgin materials, further contributing to a more sustainable manufacturing process.

Challenges and Opportunities in Bio-Based Material Development

Despite the promise of bio-based materials, challenges remain in their widespread adoption. Cost-effectiveness is a key hurdle, as the production costs of some bio-based alternatives can currently be higher than traditional plastics. However, ongoing research and development efforts are addressing these issues, and the potential cost reductions are significant as technology advances.

Furthermore, achieving consistent product quality and performance across different bio-based materials is another challenge. Scientists and engineers are continually working to refine production processes and improve material properties to meet the demands of diverse applications. These advancements are crucial for widespread adoption and acceptance of bio-based materials.

The Impact on the Circular Economy

Integrating bio-based and recycled materials into a circular economy is a powerful step towards sustainability. This approach promotes the reuse and recycling of materials, minimizing waste and maximizing resource efficiency. Implementing these strategies allows us to move away from a linear take-make-dispose model towards a more circular system that conserves resources and reduces environmental impact.

Comparative Analysis of Bio-Based and Recycled Options

A crucial aspect of adopting sustainable practices involves analyzing the comparative merits of bio-based and recycled materials. Different applications may favor one over the other, depending on factors like performance requirements, cost, and environmental impact. A comprehensive assessment of these factors is essential for informed decision-making in manufacturing and consumption choices.