Maintaining the Safety and Reliability of Your System

Regular Inspections for Early Detection

Regular inspections are crucial for maintaining the safety and reliability of your system. They allow for the identification of potential issues before they escalate into major problems, saving you time, money, and potential safety hazards. A thorough inspection should cover all critical components, including electrical wiring, mechanical parts, and safety features. By proactively addressing minor issues, you can prevent costly repairs and ensure the long-term performance and safety of your system.

These inspections should be conducted by trained personnel with the appropriate expertise and equipment. Detailed documentation of findings is essential for tracking maintenance history and identifying trends. The frequency of inspections should be based on the specific operating conditions and the nature of the system itself.

Understanding the Importance of Proper Airflow

Adequate airflow is paramount to the efficient and safe operation of any system. Poor airflow can lead to overheating, component failure, and reduced lifespan. Understanding the specific airflow requirements of your system is crucial for maintaining optimal performance. This includes considering factors like ambient temperature, humidity, and the specific design of your system.

Proper airflow also contributes to the safety of personnel working around the system. By maintaining optimal airflow, you can mitigate the risk of thermal hazards and ensure a comfortable and safe working environment.

Implementing Preventive Maintenance Protocols

Implementing a comprehensive preventive maintenance program is a proactive approach to maintaining the safety and reliability of your system. Preventive maintenance involves regularly scheduled tasks designed to identify and address potential problems before they occur. This can include cleaning, lubrication, and component replacement. This approach minimizes the risk of unexpected breakdowns and ensures consistent performance.

A well-structured preventive maintenance plan should be tailored to the specific needs of your system. This includes considering the frequency of maintenance, the specific tasks involved, and the personnel responsible for carrying them out. Clear documentation and tracking of maintenance activities are essential to ensure accountability and to evaluate the effectiveness of the program.

Addressing Environmental Factors

Environmental factors can significantly impact the safety and reliability of your system. Extreme temperatures, humidity, or exposure to corrosive substances can all contribute to premature wear and tear. Understanding how environmental factors affect your system is crucial for implementing appropriate mitigation strategies.

For example, if your system operates in a high-humidity environment, implementing measures to control humidity levels can prevent corrosion and extend the lifespan of components. Monitoring environmental conditions and adjusting operating procedures as needed ensures the system's continued performance and safety.

Regular Component Replacement and Upgrades

Regular component replacement and upgrades are essential for maintaining the safety and reliability of your system. Components, especially those subject to wear and tear, can degrade over time, increasing the risk of failure. Understanding the lifespan of different components and implementing a schedule for replacement ensures optimal performance and minimizes the likelihood of downtime.

Upgrades can also enhance the safety and reliability of your system. New technologies and improved components can often enhance performance and safety features. Regular assessments of the need for upgrades, combined with a sound plan for implementation, can keep the system up-to-date and well-maintained.

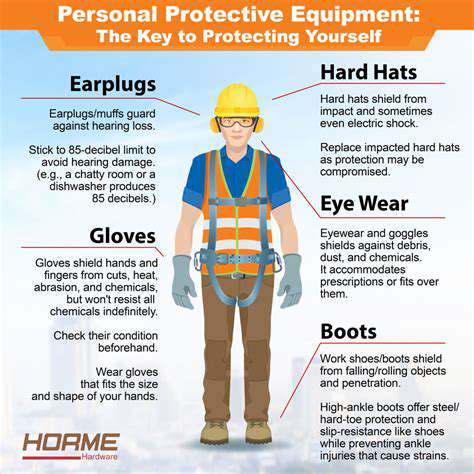

Training and Expertise

Adequate training and expertise are vital for maintaining the safety and reliability of your system. Personnel responsible for operating, maintaining, or repairing the system must possess the necessary skills and knowledge. Comprehensive training programs should cover the specifics of your system, including safety procedures, troubleshooting techniques, and component knowledge.

Regular refresher courses and opportunities for professional development ensure that personnel maintain their expertise and stay up-to-date with the latest best practices. This ongoing commitment to training ensures not just proficient operation but also a focus on safety and reliability.

Documentation and Record Keeping

Comprehensive documentation and record-keeping are essential for maintaining the safety and reliability of your system. Detailed records of inspections, maintenance activities, repairs, and any other relevant information should be meticulously maintained. This allows for easy tracking of system history, identification of trends, and efficient troubleshooting in case of issues.

Maintaining accurate records also facilitates compliance with safety regulations and standards. Proper documentation is a critical component of a robust maintenance program and contributes significantly to the overall safety and dependability of the system.

Extending the Lifespan of Your Air Conditioner

Optimizing Air Filter Maintenance

Regularly changing your air filter is crucial for maintaining optimal air quality and extending the lifespan of your air purifier. A clogged filter restricts airflow, hindering the purifier's effectiveness and potentially leading to premature wear and tear on the motor. This not only diminishes the unit's performance but also increases energy consumption as the motor works harder to compensate for the reduced airflow. By adhering to the manufacturer's recommended filter replacement schedule, you ensure the purifier continues to operate at its peak efficiency, delivering clean, healthy air throughout its intended lifespan. Furthermore, a clean filter allows the air purifier to effectively capture airborne particles, allergens, and pollutants, which contributes to better indoor air quality and overall health.

Inspecting your air filter for damage or excessive dirt accumulation is also part of preventative maintenance. This visual check can reveal issues that may not be immediately apparent, allowing you to address them promptly. If you notice significant damage, replacing the filter sooner than the recommended schedule is essential to maintain optimal performance. This proactive approach can help avoid potential malfunctions and ensure the continued effectiveness of your air purification system. Using the right filter type for your specific air purifier model is equally important to ensure compatibility and the best performance. The incorrect filter can reduce the efficiency of the entire system.

Implementing Preventative Measures for Long-Term Performance

Maintaining a consistent environment for your air purifier contributes significantly to its longevity. Avoid placing the unit near direct sunlight or heat sources, as these can increase the rate of component degradation. Placing the purifier in a stable location, away from vibrations or potential collisions, prevents unnecessary stress on its internal mechanisms. This simple preventative measure can help extend the overall lifespan of the appliance and prevent premature wear and tear.

Regular cleaning of the air purifier's exterior and any accessible components is also important. Using a soft, damp cloth to wipe down the exterior surfaces can remove dust and debris, preventing the buildup of allergens and pollutants that could affect the purifier's performance. This simple task helps maintain the aesthetics of the device and ensures its continued effectiveness. Cleaning the air intake and other accessible components, as recommended by the manufacturer, will remove accumulated dust and debris, which can significantly improve the air purifier's performance over time. Thorough cleaning is a critical aspect of maintaining optimal air quality and extending the unit's lifespan.

Consider utilizing additional features like auto-shutoff or timer settings, which can help manage energy consumption and extend the operational life of the internal components. Taking advantage of these features can help conserve energy, reduce wear and tear on the motor, and ultimately prolong the overall lifespan of your air purifier. These features can be adjusted according to your needs and preferences, contributing to a more sustainable and efficient use of your air purifier.