Preventive Maintenance Strategies for Power Steering Systems

Regular Inspections for Early Detection

Regular inspections are crucial for identifying potential issues with your power steering system before they escalate into major problems. These inspections should include checking for leaks, examining hoses for damage or deterioration, and ensuring proper fluid levels. Early detection of small problems can save you significant repair costs and potential downtime, as addressing them promptly is often far less expensive than dealing with a complete system failure.

Visual checks for leaks, especially around the pump and hoses, should be part of your regular vehicle maintenance routine. A trained technician can also assess the condition of the steering components, such as the rack and pinion, for wear and tear during these inspections.

Proper Fluid Maintenance

Maintaining the correct type and level of power steering fluid is essential for optimal system performance. Using the correct fluid, as specified by your vehicle's manufacturer, ensures proper lubrication and prevents internal component damage. Regular fluid checks and top-offs, ideally performed every 3-6 months or as recommended by the manufacturer, are vital for preventing issues related to low fluid levels.

Using the wrong type of fluid can lead to premature wear and tear on critical components, eventually requiring costly repairs. Following the manufacturer's recommendations is critical for maintaining the system's longevity and performance.

Monitoring Steering Responsiveness

Pay close attention to how your steering feels. A gradual loss of responsiveness, or a feeling of looseness or stiffness, can be early warning signs of potential power steering problems. If you notice any changes in the steering's feel, it's crucial to have the system checked by a qualified mechanic as soon as possible. This proactive approach can prevent further damage and avoid costly repairs down the line.

Keeping Belts and Hoses in Good Condition

Power steering systems rely on belts and hoses to deliver power and fluids throughout the system. Inspecting these components for any signs of damage, wear, or cracks is essential. Damaged belts can lead to reduced power steering assistance, while worn or cracked hoses can result in leaks and fluid loss. Regular visual checks and prompt replacement of damaged parts can significantly extend the life of the power steering system.

Importance of Belt Tension

Proper belt tension is critical for the efficient operation of the power steering pump. Improper tension can lead to reduced power steering assistance and excessive wear and tear on the belt. A qualified mechanic can accurately assess the belt tension and make necessary adjustments to ensure optimal performance. Ignoring this aspect can result in a malfunctioning power steering system.

Steering Wheel Alignment and Tracking

Maintaining proper steering wheel alignment is crucial for the power steering system's overall performance. Misaligned steering can place undue strain on the system's components, leading to premature wear and potential damage. Having your steering wheel alignment checked regularly, ideally during routine maintenance, will help ensure the power steering system operates efficiently and without undue stress.

Steering Wheel Vibration

Steering wheel vibration, especially at higher speeds, can indicate underlying issues with the power steering system. This could stem from worn components, misaligned parts, or even problems with the steering rack. Addressing these vibrations promptly can prevent further damage and ensure the safety of the driver. Ignoring these vibrations can lead to a potentially dangerous situation.

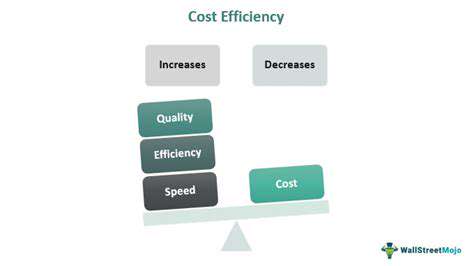

The Cost-Effectiveness of Regular Power Steering Maintenance

Factors Influencing Cost-Effectiveness

Numerous factors contribute to the overall cost-effectiveness of regular maintenance and preventative measures. These factors include the specific type of equipment or system being maintained, the frequency of use, the anticipated lifespan of the asset, and the availability of skilled labor. Understanding these variables is crucial for accurately assessing the long-term financial implications of a proactive approach. Proper planning and budgeting are vital for optimizing the cost-effectiveness of regular maintenance.

Geographic location can also significantly impact the cost-effectiveness. Variations in labor costs, material prices, and access to resources can dramatically influence the overall expense of regular maintenance routines. For example, a region with high labor costs might necessitate the use of automated systems to reduce personnel expenses.

Preventive Maintenance Strategies

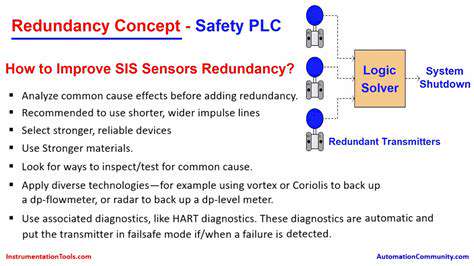

Implementing preventive maintenance strategies is often more cost-effective than reactive repairs. These strategies involve scheduled inspections, replacements of parts before they fail, and routine cleaning. By addressing potential issues before they escalate, businesses can avoid costly breakdowns and downtime. This proactive approach can also extend the lifespan of equipment and improve its overall performance.

Predictive maintenance, which utilizes sensor data and advanced analytics to anticipate potential failures, is another crucial strategy. It allows for timely interventions, minimizing disruptions and reducing costly repairs. This approach offers a substantial return on investment by preventing unexpected breakdowns and maximizing equipment uptime.

Impact on Downtime and Productivity

Regular maintenance can significantly reduce downtime, a crucial factor in assessing the cost-effectiveness of the strategy. By addressing potential issues proactively, businesses can minimize unexpected breakdowns, ensuring uninterrupted operations and maximizing productivity. Minimizing downtime is essential for maintaining a smooth workflow and preventing lost revenue.

Return on Investment (ROI) Analysis

Evaluating the return on investment (ROI) of regular maintenance is essential for justifying the associated costs. Calculating the ROI involves comparing the cost of maintenance with the savings from reduced downtime, fewer repairs, and extended equipment lifespan. Analyzing historical data is crucial to accurately predict the ROI of these investments.

A thorough ROI analysis will provide a clear picture of whether the costs associated with regular maintenance are justifiable in the long run. This analysis is critical for securing budget approval and demonstrating the value proposition of preventative maintenance strategies.

Comparison with Reactive Maintenance

Reactive maintenance, or repairing equipment only after a failure, is often more expensive than a proactive approach. It often involves substantial repair costs, lost productivity due to downtime, and potential safety risks associated with unplanned interventions. The difference in cost-effectiveness between the two approaches is substantial and highlights the benefits of preventive maintenance.

Long-Term Financial Implications

The long-term financial implications of regular maintenance are substantial and often overlooked. By investing in preventative measures, businesses can avoid costly repairs, extended downtime, and potential safety hazards. This proactive approach can lead to significant cost savings over the lifespan of the equipment or system.

Regular maintenance can also lead to improved efficiency and increased output over time. This sustained performance translates into tangible financial benefits by reducing operational costs and maximizing profitability. Predictable performance and reduced operational costs are crucial for long-term financial stability and growth.