The magic happens when exhaust gases get rerouted into the intake manifold. These recycled fumes mix with fresh air-fuel combinations, creating a diluted mixture that burns cooler. This temperature drop is crucial because it directly impacts the formation of harmful nitrogen oxides, making EGR systems environmental game-changers.

The Role of the EGR Cooler

Positioned as the EGR system's unsung hero, the cooler performs the vital task of temperature regulation. Without this component, scorching exhaust gases - often exceeding 1200°F - would wreak havoc on sensitive engine parts. The cooler intercepts these fiery fumes, dropping their temperature to safer levels before they reach critical components.

Engineers designed these coolers as sophisticated heat exchangers. They work by channeling engine coolant around the exhaust flow, creating a thermal exchange that can reduce gas temperatures by several hundred degrees. This thermal management protects valves, pistons, and other components from premature wear and catastrophic failure.

Benefits of a Properly Functioning EGR Cooler

When operating at peak efficiency, EGR coolers deliver measurable benefits. They extend engine lifespan by preventing thermal degradation of components that would otherwise fail under excessive heat stress. Fleet managers particularly appreciate the reduced maintenance costs associated with well-maintained EGR systems.

The environmental impact cannot be overstated - functional EGR coolers slash NOx emissions by up to 50% in some applications. This dramatic reduction helps vehicles meet increasingly stringent emissions standards while contributing to cleaner urban air quality. The technology represents a critical bridge between internal combustion engines and future zero-emission vehicles.

Consequences of a Malfunctioning EGR Cooler

When EGR coolers fail, the consequences cascade through the entire engine system. Unchecked exhaust temperatures can warp cylinder heads, damage turbochargers, and even cause complete engine seizures in extreme cases. Drivers might notice symptoms ranging from mysterious check engine lights to sudden power loss during acceleration.

Beyond mechanical issues, faulty coolers create regulatory nightmares. Emissions testing failures become inevitable as NOx levels spike, potentially resulting in expensive fines and mandatory repairs. In commercial applications, these failures can ground entire fleets until repairs are completed.

How EGR Coolers Work: A Detailed Look at the Process

Understanding the Role of Exhaust Gas Recirculation (EGR)

Contemporary emissions control relies heavily on EGR technology. These systems create a carefully calibrated loop where exhaust gases re-enter the combustion cycle, disrupting the conditions that create harmful NOx compounds. This elegant solution helps manufacturers meet tough environmental standards while maintaining engine efficiency - a balancing act that defines modern automotive engineering.

The science behind EGR revolves around combustion thermodynamics. By introducing inert exhaust gases into fresh air-fuel mixtures, the system lowers peak flame temperatures below the threshold where nitrogen oxides form. This temperature modulation occurs without significantly compromising engine power output when properly calibrated.

Exhaust Gas Recirculation: The Fundamental Concept

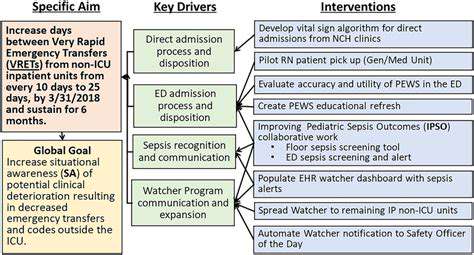

At its core, EGR technology creates a controlled feedback loop. Sensors and valves work in concert to meter precise amounts of exhaust gas back into the intake stream. This recirculation changes the fundamental chemistry of combustion, substituting some oxygen molecules with carbon dioxide and water vapor from previous combustion cycles.

The process demands remarkable precision - too much recirculation starves the engine of oxygen, while too little fails to control emissions. Modern engine control units use complex algorithms to adjust EGR flow based on real-time operating conditions, creating an adaptive system that responds to everything from altitude changes to turbocharger boost levels.

The Critical Role of the EGR Cooler

These specialized heat exchangers represent the EGR system's thermal management solution. Without cooling, reintroduced exhaust gases would carry enough heat to potentially damage intake components and disrupt the carefully balanced air-fuel mixture. The cooler serves as a temperature gatekeeper, ensuring only properly conditioned gases re-enter the combustion chamber.

The Cooling Process in Detail

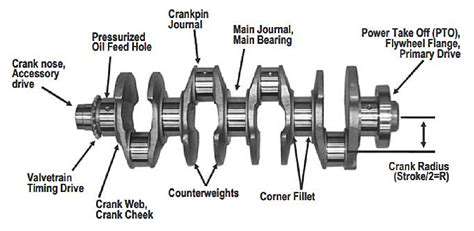

Inside the cooler's compact housing, a network of tubes or plates creates maximum surface area for heat transfer. Engine coolant circulates through these structures, absorbing thermal energy from exhaust gases flowing in adjacent passages. Advanced designs may incorporate turbulence generators to enhance heat exchange efficiency without creating excessive backpressure.

EGR Cooler Design and Function

Manufacturers employ various configurations - from simple shell-and-tube designs to intricate stacked-plate arrangements. Material selection proves critical, with stainless steel alloys common for their resistance to corrosion and thermal fatigue. Some high-performance applications use exotic materials like Inconel to withstand extreme temperatures while minimizing weight.

Maintaining Optimal EGR Cooler Performance

Preventative maintenance preserves cooler efficiency. Technicians should inspect for carbon buildup that can restrict flow, check coolant quality, and verify proper mounting to prevent vibration-induced failures. Many manufacturers recommend specific service intervals that account for normal performance degradation over time.

Troubleshooting EGR Cooler Issues

Diagnostic procedures typically start with visual inspections for soot deposits or coolant leaks. Pressure testing can reveal internal failures, while thermal imaging helps identify clogged passages. Advanced diagnostics might involve exhaust gas temperature analysis before and after the cooler to verify proper heat rejection rates.