Enhanced Battery Management Systems (BMS): Precision Control

Advanced Monitoring Capabilities

Enhanced Battery Management Systems (BMS) incorporate sophisticated monitoring technologies to track real-time battery health parameters, including cell voltage, temperature, and current flow. This continuous data collection allows for proactive identification of potential issues like cell imbalance or thermal runaway. These systems can detect anomalies before they escalate into serious problems, significantly extending the lifespan and safety of the EV battery pack.

By meticulously monitoring every cell within the battery pack, BMS systems can pinpoint any deviation from the ideal operating parameters. This level of precision is crucial in ensuring optimal battery performance and preventing premature degradation, a significant advancement over older BMS designs.

Optimized Charging Strategies

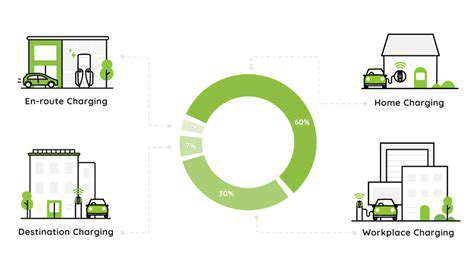

Modern BMS systems employ sophisticated algorithms to optimize the charging process, maximizing energy input while preventing overcharging or damage to the battery cells. This involves dynamic adjustments to charging rates based on real-time battery conditions, preventing damage and extending the battery's lifespan through intelligent charging strategies.

Different charging protocols can be implemented depending on the battery chemistry and the specific charging infrastructure. The BMS adapts to these different charging conditions, ensuring a safe and efficient charging experience, crucial for both home and public charging stations.

Improved Thermal Management

Maintaining optimal battery temperature is paramount for performance and safety. Enhanced BMS systems integrate advanced thermal management strategies that actively regulate the temperature of individual battery cells, preventing overheating and promoting uniform cell operation. This precision thermal control is essential for achieving maximum energy density and longevity.

Sophisticated cooling systems and strategically placed thermal sensors work in tandem with the BMS to manage heat dissipation effectively. This level of thermal control is a key factor in preventing thermal runaway, a critical safety concern in EV battery technology.

Predictive Maintenance and Failure Prevention

The advanced data analysis capabilities of an enhanced BMS enable predictive maintenance. By analyzing historical data and real-time monitoring, the system can anticipate potential failures and alert users well in advance, allowing for proactive maintenance and minimizing unexpected downtime. This proactive approach is crucial for preventing costly repairs and ensuring consistent vehicle operation.

Enhanced Safety Features

Advanced BMS systems incorporate robust safety features to mitigate risks associated with battery operation. These safety mechanisms include advanced fault detection and isolation capabilities, automatically disconnecting faulty cells or sections of the battery pack to prevent dangerous situations. Safety is paramount in EV technology, and a sophisticated BMS is a crucial component in ensuring the safety of the driver and bystanders.

The enhanced safety features are a critical component in ensuring the reliability and safety of electric vehicle operation. These features are designed to prevent unexpected issues and ensure the longevity of the battery pack.

Data Logging and Analysis Tools

Enhanced BMS systems often include comprehensive data logging and analysis tools, providing valuable insights into the battery's performance over time. These tools allow for detailed analysis of charging cycles, discharge patterns, and temperature fluctuations, enabling engineers and technicians to identify trends and optimize battery management strategies. This data is crucial for continuous improvement and development in EV battery technology.

The ability to analyze the data collected by the BMS allows for the identification of patterns and anomalies in battery behavior. This data can be used to improve the design of future battery systems and optimize the performance of existing ones.

Integration with Vehicle Control Systems

Modern BMS systems are designed to seamlessly integrate with the vehicle's control systems, enabling coordinated operation between the battery and other vehicle components. This integration allows for optimal energy management, ensuring the battery is used efficiently in conjunction with other vehicle systems. This optimized control is essential for maximizing the range and performance of electric vehicles.

The BMS acts as a central control hub, communicating with other vehicle systems to ensure efficient energy distribution. This allows for more sophisticated control over the battery and enhances the overall driving experience.

Advanced Manufacturing Processes: Scaling Up Production

Scaling Up Battery Production

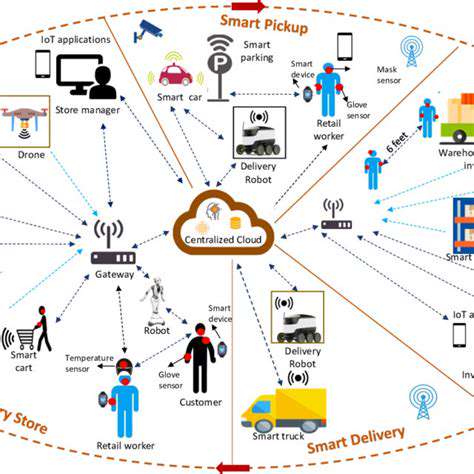

Scaling up the production of EV batteries requires a multifaceted approach, encompassing not only the optimization of existing processes but also the development of entirely new, more efficient manufacturing techniques. This includes streamlining the supply chain for raw materials, such as lithium, cobalt, and nickel, ensuring consistent quality and timely delivery. Efficient material handling systems are crucial for minimizing downtime and maximizing throughput in the production lines. Furthermore, automation plays a significant role in improving productivity and reducing labor costs while maintaining safety standards in the high-energy environment of battery manufacturing.

The transition to high-volume production necessitates significant investment in advanced robotics and automation systems. These systems can handle complex tasks like precise material dispensing, intricate assembly, and quality control checks, leading to increased output and reduced human error. The integration of advanced data analytics tools is also essential for optimizing production processes, identifying bottlenecks, and predicting potential issues. Real-time monitoring of equipment performance and material flow can provide crucial insights for proactive maintenance and process improvement, ultimately contributing to the overall efficiency and cost-effectiveness of the entire operation.

Advanced Techniques in Battery Cell Manufacturing

Advanced manufacturing processes are critical to improving the efficiency and quality of EV battery cell production. This includes the use of innovative techniques like 3D printing for creating intricate electrode structures, enabling higher energy density and improved performance. These techniques offer significant potential in terms of customization and scalability, allowing for the creation of battery cells tailored to specific vehicle requirements. Moreover, advanced techniques like nanomaterials integration can enhance the electrochemical properties of the battery components, leading to longer lifespan and increased safety.

Another critical aspect of advanced cell manufacturing is the development of novel electrode materials with enhanced performance characteristics. This involves exploring new materials and optimizing their composition to achieve higher energy density and faster charging rates. These advancements are essential for meeting the increasing demands for range and performance in electric vehicles. Furthermore, advanced techniques for battery cell testing and quality control are vital to ensure consistent product quality and safety, preventing potential hazards during operation.

Implementing advanced techniques in battery cell manufacturing not only increases the production capacity but also reduces the cost per unit, making EV batteries more affordable and accessible. The focus on sustainability throughout the process, from material sourcing to waste management, is also paramount. This holistic approach to advanced manufacturing is crucial for the wider adoption of electric vehicles and the transition to a sustainable future.

Advanced manufacturing techniques for battery cell production also include incorporating more sustainable and environmentally friendly materials and processes. This is crucial for mitigating the environmental impact of battery production and aligning with global sustainability goals. The development of closed-loop systems for material recovery and recycling is essential for minimizing waste and maximizing resource utilization.