Grip Enhancement for Electric Acceleration

Grip Enhancement Techniques for Electric Accelerators

Enhancing grip on electric accelerators plays a pivotal role in achieving precise control while reducing unintended slips, particularly during intensive operations or under adverse conditions. Implementing effective grip improvement methods can dramatically boost both performance and safety. Mastering the subtle differences among various grip styles proves essential for identifying the optimal approach tailored to specific requirements. Material choices and design elements significantly impact the grip's overall efficiency.

Multiple variables influence the success of any grip enhancement system. Texture characteristics, moisture absorption capacity, and long-term durability all emerge as critical evaluation criteria. Ergonomic compatibility between hand anatomy and accelerator interface must remain a central focus during the design phase. Strategic grip enhancement methodologies can effectively mitigate fatigue and discomfort during prolonged usage periods.

Ergonomic Considerations for Accelerator Grips

Human factors engineering assumes paramount importance when developing comfortable and functional electric accelerator grips. Ideal grip designs must accommodate the hand's natural contours and the operator's typical interaction angle with the control mechanism. Attention to these physiological details substantially decreases physical strain during extended operation cycles.

Grip dimensions and contours require careful customization based on individual hand measurements and accelerator specifications. This individualized strategy guarantees optimal tension balance - neither restrictive nor excessive - thereby maximizing both comfort and command. Thorough analysis of user hand positioning and movement dynamics during accelerator operation proves indispensable for achieving superior grip architecture.

Material Selection and Durability

Material specification represents a decisive factor in ensuring grip longevity and operational reliability. Selected substances must demonstrate exceptional resistance to mechanical degradation while maintaining performance characteristics. Environmental resilience against moisture intrusion and thermal variation remains particularly crucial for exterior or industrial implementations.

Material hygroscopic properties demand special consideration to preserve consistent traction. Effective moisture management becomes especially critical during intense operation or in humid climates. Engineered surface textures significantly improve frictional characteristics, creating essential slip resistance for safety and precision control.

Customizable Grip Solutions

Adjustable grip configurations provide substantial benefits for optimizing operator experience. Users can modify various parameters to match personal requirements and comfort preferences, resulting in enhanced control effectiveness. This adaptability facilitates ideal ergonomic alignment regardless of anatomical variations.

Contemporary customizable systems permit modifications to texture profiles, dimensional parameters, and material composition. Such flexibility proves especially advantageous for operators with unique physiological characteristics or specialized usage requirements. Application-specific customization capability stands as a defining advantage of modern grip solutions.

Grip Enhancement for Specific Applications

Diverse operational contexts necessitate distinct grip optimization strategies. Competitive motorsport environments might emphasize minimal mass and instantaneous feedback, while industrial applications could prioritize chemical resistance and structural robustness. Thorough analysis of application-specific demands proves essential for selecting appropriate enhancement methodologies.

High-intensity or continuous operation scenarios often require materials with exceptional wear resistance. Material specification and structural engineering must precisely align with operational parameters to ensure sustained performance throughout the product lifecycle under demanding conditions.

Advanced Materials and Technologies

Advanced Polymer Composites for Enhanced Grip

Contemporary electric vehicle tires increasingly integrate sophisticated polymer matrix materials to optimize traction characteristics. These composite structures, frequently incorporating carbon nanofibers or similar reinforcement elements, improve structural rigidity and deformation resistance under extreme loading. This enhanced material integrity directly correlates with improved directional stability and turning precision - critical parameters for electric vehicle dynamics. Specialized polymer formulations additionally contribute to mass reduction, potentially improving both acceleration profiles and deceleration performance.

Evolution in high-performance polymer technology has enabled significant improvements in surface adhesion maintenance across diverse pavement conditions. This capability proves particularly valuable for electric vehicles, which typically demand superior stability during power application and braking compared to conventional automotive platforms.

Nanotechnology Integration for Enhanced Durability

Molecular-scale engineering significantly contributes to extending the service life of electric vehicle tires. Nanostructured additives incorporated within the tire matrix increase abrasion resistance, thereby prolonging operational lifespan. This technological advancement proves especially beneficial for electric vehicles operating under demanding performance conditions that impose substantial mechanical stress on tire components.

Nanomaterial integration additionally enhances resistance to penetration damage and surface lacerations, potentially decreasing replacement frequency and reducing total ownership costs for electric vehicle operators.

Innovative Tread Patterns for Superior Traction

Modern tread designs undergo rigorous optimization to maximize road surface interaction across varying meteorological conditions. Sophisticated computer simulations and experimental validation processes develop tread geometries that maximize contact patch effectiveness, particularly during precipitation or winter conditions. This engineering focus results in improved directional stability and handling precision, fundamental requirements for safe electric vehicle operation.

Advanced Manufacturing Processes for Precision

Manufacturing precision remains critical for ensuring consistent electric vehicle tire performance. Cutting-edge fabrication techniques including additive manufacturing and precision laser ablation enable production of complex tire architectures with exceptional dimensional consistency. This manufacturing accuracy ensures predictable performance characteristics across production batches, minimizing grip variation. Such advanced processes simultaneously reduce material waste streams, contributing to more sustainable production ecosystems.

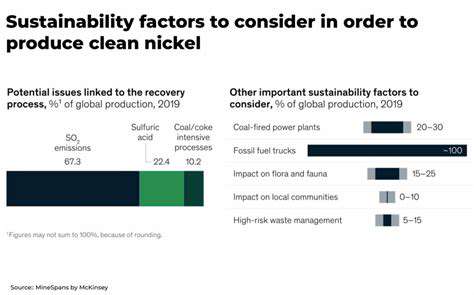

Sustainable Material Choices for Environmental Impact

Environmental considerations are driving material innovation in electric vehicle tire development. Manufacturers are actively investigating recycled content and plant-derived polymer alternatives to minimize ecological impact. This sustainable approach not only decreases reliance on non-renewable resources but also aligns with broader electric vehicle industry environmental objectives. Responsible material selection contributes to greener tire lifecycle management from production through disposal.

Computational Modeling and Testing for Performance Optimization

Advanced simulation platforms enable comprehensive performance prediction for electric vehicle tires across operational scenarios. These digital models analyze tire behavior during acceleration, braking, and cornering maneuvers by incorporating empirical data from real-world testing. Iterative model refinement leads to continuous improvement in both design methodology and production techniques, culminating in tires that deliver superior traction and efficiency. Controlled environment testing validates simulation accuracy, ensuring development of safe, high-performance electric vehicle tires.