Space-based environments offer a unique opportunity for pharmaceutical research by minimizing the impact of numerous environmental variables that can influence results on Earth. These variables, including gravity, atmospheric pressure, and even subtle fluctuations in temperature and humidity, can introduce inconsistencies into experimental data. In the microgravity conditions of space, researchers can isolate the effects of specific drug compounds and formulations, leading to more precise and reliable results that might otherwise be obscured by confounding factors in terrestrial laboratories.

Beyond the Vehicle: A Holistic Approach to Sustainability

Embracing a Circular Economy Model

Beyond the immediate design and manufacturing stages of a vehicle, a truly sustainable approach necessitates a holistic view encompassing the entire lifecycle. This perspective, often termed a circular economy model, prioritizes resource efficiency, material reuse, and waste minimization throughout the product's existence. This involves considering not only the raw materials used in the vehicle's construction but also the energy required for its production, operation, and eventual disposal. By embracing a circular economy, we can significantly reduce the environmental footprint of the automotive industry, moving away from a linear take-make-dispose model towards a more regenerative and closed-loop system.

Implementing this model requires innovative approaches to material selection, aiming for the use of recycled and renewable materials wherever possible. Furthermore, strategies for disassembly and component reuse need to be integrated into the design process. This proactive approach goes beyond simply reducing emissions during operation; it seeks to minimize the overall environmental impact throughout the entire lifecycle of the vehicle, from cradle to grave.

Sustainable Manufacturing Processes

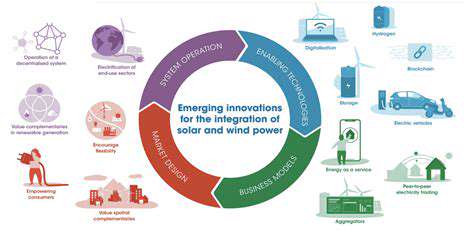

Green engineering principles extend beyond the vehicle itself, encompassing the entire manufacturing process. Sustainable manufacturing practices must be implemented at each stage, from sourcing raw materials to the final assembly. This includes scrutinizing energy consumption during production, optimizing transportation logistics to minimize fuel use and emissions, and implementing waste reduction strategies throughout the factory. Finding alternative energy sources for factory operations, such as solar or wind power, are key elements in this holistic approach.

Furthermore, rigorous evaluation and improvement of supply chains are crucial. This involves investigating the environmental impact of each supplier and working collaboratively to implement more sustainable sourcing practices. By minimizing waste, maximizing resource efficiency, and promoting cleaner production methods, we can significantly reduce the environmental burden of vehicle manufacturing and create a more responsible and environmentally conscious industry.

Utilizing advanced technologies, such as 3D printing and advanced robotics, can also play a significant role in optimizing manufacturing processes, reducing material waste, and minimizing energy consumption. Integrating these technologies into the manufacturing workflow can lead to substantial improvements in sustainability performance.

Finally, the concept of a cradle-to-grave approach should be extended to consider end-of-life management. This includes designing vehicles for easy disassembly, enabling the recovery and reuse of valuable materials. This responsible approach ensures that the vehicle's environmental impact is minimized throughout its entire lifecycle, from its initial creation to its eventual recycling or disposal.

This holistic approach to sustainable manufacturing is essential for achieving a truly green automotive industry, one that prioritizes environmental protection and resource conservation.

Implementing these practices will require a collaborative effort involving industry, government, and consumers, to ensure that the manufacturing processes of the future are truly sustainable and environmentally responsible.