Minimizing VOC Emissions in Automotive Paint Shops

Effective Ventilation Systems

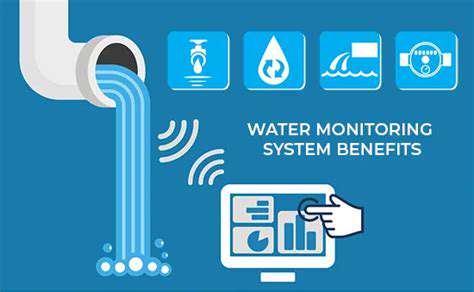

Proper ventilation is paramount in minimizing VOC emissions. Implementing a comprehensive ventilation system that effectively captures and exhausts volatile organic compounds (VOCs) at the source is crucial. This includes strategically placed exhaust fans, optimized air flow patterns, and regular maintenance to ensure optimal performance. A properly designed system can significantly reduce the concentration of VOCs in the air, preventing them from escaping into the atmosphere and contributing to air pollution.

Careful consideration should be given to the type of ventilation system, such as localized exhaust ventilation (LEV) systems or general ventilation systems, to ensure that the specific needs of the paint application process are met. Regular inspections and maintenance of the ventilation system are essential to maintain its effectiveness and prevent leaks or inefficiencies that could allow VOCs to escape. This proactive approach ensures sustained performance, minimizing emissions over time.

Solvent Selection and Substitution

Choosing low-VOC or VOC-free solvents is a key strategy in reducing emissions. Manufacturers should prioritize solvents with lower vapor pressures and lower overall VOC content. This approach directly impacts the amount of VOCs released during the painting process. Researching and implementing alternative solvents that achieve the desired paint performance without relying on high-VOC options is a critical step toward sustainable practices. This necessitates collaborations with solvent suppliers and paint manufacturers to find effective low-VOC or zero-VOC substitutes.

Furthermore, proper storage and handling of solvents are vital to prevent spills and evaporation, which contribute to VOC emissions. Implementing strict procedures for solvent use and storage can significantly reduce VOC emissions and promote a safer work environment. This includes using appropriate containers, implementing spill containment measures, and ensuring proper disposal practices to prevent environmental contamination.

Improved Paint Application Techniques

Optimizing the paint application process itself is another critical aspect of minimizing VOC emissions. Techniques such as using spray guns with low-pressure settings, minimizing overspray, and employing proper surface preparation methods contribute significantly to reducing VOC emissions. These methods reduce the overall amount of paint needed for a given task, resulting in less material evaporation and fewer VOCs released into the air.

Using appropriate application equipment and training employees on proper techniques are crucial. Regular monitoring and adjustments to the application process are essential to ensure optimal results and minimize VOC emissions. This includes evaluating factors like paint viscosity, spray gun settings, and surface preparation to fine-tune the process and ensure efficiency while reducing VOCs.

Waste Management and Recycling

Implementing a robust waste management system is essential for minimizing VOC emissions in automotive paint shops. This includes proper handling and disposal of paint scraps, solvents, and other waste materials to prevent uncontrolled emissions. Implementing strategies to recycle or reuse materials whenever possible is crucial to reduce the environmental impact and waste generation.

Careful consideration of the entire waste stream is vital. This includes the collection, transport, and treatment or disposal of waste materials. Working with certified waste management companies that specialize in handling hazardous materials and recycling processes is essential. This minimizes the risk of improper disposal and maximizes the potential for material reuse and resource recovery.

Sustainable Sourcing of Raw Materials for Automotive Coatings

Optimizing Material Selection for Reduced Environmental Impact

Sustainable sourcing of raw materials is crucial for automotive coatings in the context of green manufacturing. A key aspect of this process involves careful material selection to minimize the environmental footprint throughout the entire lifecycle of the product. This includes considering factors like the extraction, processing, and transportation of raw materials, as well as the potential for recycling and reuse at the end of the vehicle's life. Choosing materials with lower embodied energy and reduced reliance on finite resources is paramount. Furthermore, the selection process should prioritize materials derived from renewable or recycled sources, thereby minimizing the environmental burden associated with virgin material extraction.

Materials with lower toxicity throughout their lifecycle are also important considerations. This reduces potential harmful emissions during production and the use phase of the coating. Evaluating the potential for hazardous waste generation during the various stages of manufacturing is critical for achieving a truly sustainable supply chain. The use of alternative solvents and pigments with lower toxicity profiles can significantly reduce the environmental impact and ensure worker safety. Ultimately, a proactive approach to material selection can pave the way for a more environmentally conscious and responsible automotive coating industry.

Implementing Responsible Supply Chain Practices

Beyond material selection, robust supply chain practices are essential for ensuring sustainable sourcing. This includes establishing clear, transparent, and ethical sourcing policies that extend to all tiers of the supply chain. Thorough due diligence must be conducted to verify that suppliers adhere to environmental and social responsibility standards. Evaluating the environmental impact of each supplier's operations, including their energy consumption, waste management practices, and water usage, is crucial to identifying areas for improvement and promoting sustainable practices throughout the chain. This commitment to responsible sourcing not only mitigates environmental risks but also fosters trust and transparency with consumers.

Building strong relationships with suppliers who share a commitment to sustainability is vital. This collaboration can lead to the development of innovative solutions and the exploration of new, sustainable materials. Regular audits and assessments of suppliers' performance are critical to maintain accountability and ensure ongoing compliance with sustainability standards. Open communication and collaboration with suppliers are fundamental to achieving a truly sustainable supply chain and optimizing the environmental performance of automotive coatings.

Monitoring and measuring the environmental impact of the entire supply chain is also essential. Implementing robust tracking and reporting systems allows for transparency and accountability. This data-driven approach enables continuous improvement and helps to identify areas where further optimization is needed. Ultimately, a comprehensive approach to supply chain management ensures that the sourcing of raw materials for automotive coatings aligns with environmental sustainability goals.

Waste Reduction and Recycling Strategies in Automotive Paint Operations

Optimizing Solvent Usage

Solvent-based paints are a crucial component in automotive manufacturing, yet their use often comes with significant environmental concerns. Implementing a comprehensive solvent management system, including rigorous inventory control, optimized application techniques, and the use of low-VOC (volatile organic compound) alternatives, is paramount. This approach not only reduces waste but also lowers the environmental impact associated with solvent evaporation and potential air pollution. Proper training of personnel on proper handling and disposal procedures is also essential to preventing accidents and misuse.

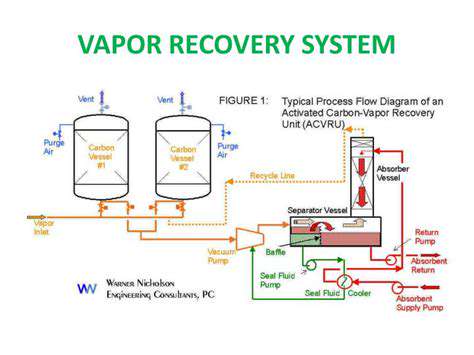

Waste reduction in solvent usage goes beyond simply minimizing consumption. Implementing closed-loop systems, where solvents are recovered and reused, is a highly effective strategy. This approach significantly reduces the need for fresh solvent purchases and lowers the amount of waste requiring disposal. The initial investment in these systems may seem substantial, but the long-term cost savings and environmental benefits often outweigh the initial outlay.

Improving Paint Application Efficiency

Minimizing paint overspray and ensuring precise application techniques are critical to reducing waste. Advanced application equipment, such as airless sprayers and electrostatic sprayers, can significantly reduce material loss compared to conventional methods. Proper training for employees on these techniques is essential to maximizing efficiency and minimizing waste.

By precisely targeting paint application, we can ensure minimal material is wasted as overspray. This approach not only reduces waste but also saves material costs. Implementing these strategies directly impacts the bottom line while contributing to a more sustainable manufacturing process.

Implementing Water-Based Coatings

Transitioning to water-based paints offers a significant opportunity for waste reduction and environmental improvement. Water-based paints typically have a lower environmental impact compared to solvent-based systems, generating less hazardous waste and reducing the need for volatile organic compound (VOC) emissions control. The shift towards water-based coatings is a crucial step towards a greener manufacturing process, promoting both environmental responsibility and cost-effectiveness. The reduced need for specialized waste management procedures for solvent-based paints also benefits the operation.

Developing a Comprehensive Recycling Program

Recycling programs for paint waste and associated materials are essential. This includes the proper segregation of different paint types and components for efficient recycling. Partnering with certified recycling facilities ensures that materials are handled responsibly and that valuable resources are recovered. A comprehensive recycling program not only reduces waste but also promotes the circular economy, fostering a more sustainable and closed-loop manufacturing process. The implementation of a recycling program should be supported by clear guidelines and training for staff.

Waste Characterization and Analysis

Understanding the composition of paint waste is critical for effective waste management strategies. A thorough analysis of the waste stream provides valuable data on the types of materials present and their proportions. This information is essential for designing appropriate recycling and disposal methods. Accurate waste characterization data allows for the selection of the most efficient and cost-effective solutions, minimizing environmental impact and maximizing resource recovery.

Employee Training and Awareness

Educating and engaging employees in waste reduction and recycling initiatives is paramount. Comprehensive training programs should cover proper handling procedures, waste segregation techniques, and the importance of environmental responsibility. Raising awareness of the environmental impact of waste and the benefits of recycling fosters a culture of sustainability within the workplace. Empowering employees with the knowledge and skills to participate in waste reduction initiatives is crucial for long-term success.

Partnering with Recycling Facilities

Building strong relationships with reputable recycling facilities is essential for efficient waste management. These facilities possess the expertise and infrastructure to handle various paint types and components safely and responsibly. Collaboration with recycling facilities helps optimize the recycling process, ensuring that valuable materials are recovered and reintroduced into the production cycle. Choosing the right partner is crucial for ensuring compliance with environmental regulations and maximizing the recovery of valuable resources.