Battery Management System (BMS) and Internal Processes

Battery Chemistry and its Impact

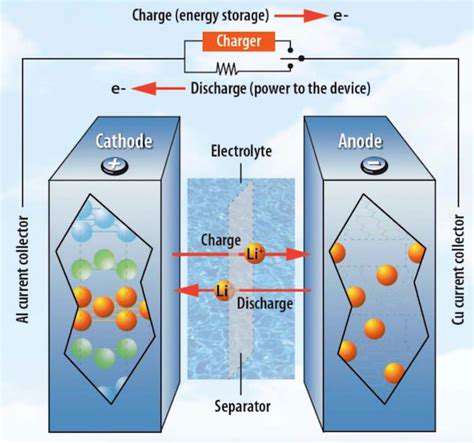

Understanding the underlying chemistry of the battery is crucial for comprehending its lifespan. Different battery chemistries, such as Lithium-ion (Li-ion), Nickel-metal hydride (NiMH), and Lead-acid, exhibit varying characteristics regarding their susceptibility to degradation. Li-ion batteries, while prevalent in EVs, are sensitive to factors like temperature fluctuations, overcharging, and deep discharging, which can accelerate the decline in performance and capacity over time. The chemical reactions within these cells are complex and influenced by numerous internal and external conditions, impacting battery longevity significantly.

Furthermore, the specific materials used in the cathode and anode, along with the electrolyte, directly affect the battery's overall performance and susceptibility to various degradation mechanisms. The choice of these materials impacts the battery's voltage, current output, and thermal stability. This intricate interplay of chemical components and processes within the battery directly contributes to the overall life expectancy of the EV battery.

Internal Resistance and Thermal Management

Internal resistance, a key factor affecting battery performance, represents the opposition to the flow of current within the battery cells. Higher internal resistance leads to greater energy loss during charging and discharging cycles, ultimately reducing the battery's overall efficiency and capacity over time. Effective thermal management is essential to mitigate the negative impact of heat generation within the battery pack. Excessive heat can accelerate degradation processes, shorten the lifespan, and even pose safety risks.

Thermal runaway, a potentially catastrophic event, can occur if the battery pack's temperature exceeds a critical threshold. Sophisticated thermal management systems, including liquid cooling and advanced heat dissipation strategies, are crucial for maintaining optimal operating temperatures and preventing thermal runaway, thereby extending the EV battery's operational lifespan and safety.

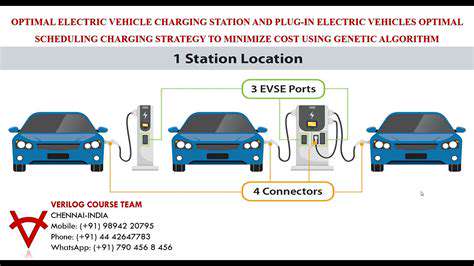

Charging and Discharging Cycles and Their Effects

The number of charge and discharge cycles a battery undergoes significantly impacts its lifespan. Each cycle introduces stress on the battery's components, leading to a gradual decline in its capacity and performance. Factors like the depth of discharge (DoD) and the rate of charging and discharging play crucial roles in the rate of degradation. Optimizing charging and discharging protocols can substantially extend the battery's operational life. Strategies like limiting deep discharges, utilizing appropriate charging speeds, and employing advanced battery management systems (BMS) are critical for prolonging battery life.

Battery Management System (BMS) Functionality and Role

The BMS acts as the central nervous system for the battery pack, monitoring and regulating its various parameters. It continuously measures voltage, current, temperature, and other critical metrics across all cells within the battery pack. This real-time data allows the BMS to optimize charging and discharging processes, preventing overcharging, over-discharging, and thermal runaway. Advanced BMS algorithms adapt to the battery's specific conditions, ensuring optimal performance and prolonging its service life.

By actively managing and controlling the battery's internal processes, the BMS effectively mitigates stress on the battery's components and prevents premature degradation. The accuracy and sophistication of the BMS directly influence the overall lifespan and reliability of the EV battery, contributing significantly to the vehicle's overall operational efficiency.

Battery Chemistry and Design Considerations

Lithium-ion Battery Chemistry

Lithium-ion batteries (LIBs) are the dominant technology in electric vehicles (EVs) due to their high energy density, relatively long lifespan, and favorable safety profile. Different types of lithium-ion chemistries exist, each with unique characteristics impacting performance and cost. For example, lithium nickel manganese cobalt oxide (NMC) batteries offer a good balance of energy density and cost, while lithium iron phosphate (LFP) batteries are known for their safety and longevity, although with a slightly lower energy density. Understanding the nuances of these chemistries is crucial for optimizing EV battery life and performance.

The selection of a specific lithium-ion chemistry directly influences the overall battery pack design. Factors such as thermal management, safety features, and material compatibility must be carefully considered, and the choice often depends on the specific application and desired performance characteristics of the EV.

Electrode Material Properties

The performance of lithium-ion batteries is significantly affected by the properties of the electrode materials, particularly their capacity, rate capability, and cycle life. The active materials within the cathode and anode play a critical role in determining the energy density and power delivery capabilities of the battery. Advanced materials research continues to push the boundaries of battery performance by improving the efficiency and stability of these electrode components.

The choice of electrode materials directly impacts the overall battery cost and manufacturing process, and finding the optimal balance between performance and cost is a key consideration in EV battery design.

Electrolyte Selection

The electrolyte, the liquid or solid substance that facilitates ion transport between the electrodes, plays a vital role in battery performance. Different electrolytes exhibit varying degrees of safety, conductivity, and stability at different temperatures. The choice of electrolyte is crucial for ensuring the safe and reliable operation of the battery pack within the harsh operating conditions of an EV, especially during extreme temperatures.

Careful consideration of the electrolyte's properties is essential to ensure both long-term battery life and safety features in an EV. The interplay between electrolyte, electrode, and cell design is paramount in achieving high-performance batteries.

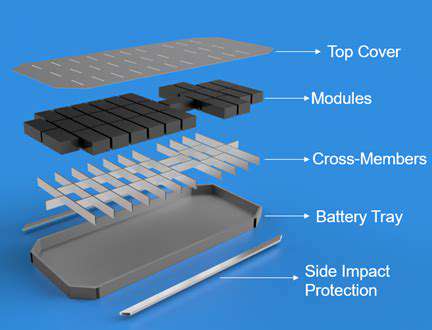

Cell Design and Manufacturing

The physical structure of the individual battery cells, including their geometry, internal components, and manufacturing processes, directly affects their performance and longevity. Optimizing the cell design is crucial for enhancing the overall efficiency and safety of the battery pack. Factors like cell size, electrode thickness, and separator materials play a significant role in determining the battery's capacity, power output, and thermal management capabilities.

Thermal Management Systems

Maintaining optimal operating temperatures is essential for maximizing battery performance and lifespan. Thermal management systems are critical for preventing overheating, which can lead to reduced capacity, accelerated degradation, and safety risks. These systems must effectively dissipate heat generated during charging and discharging cycles to ensure that the battery operates within its safe temperature range. Sophisticated thermal management designs are necessary to support the demanding operating conditions of EVs, especially during high-power acceleration and rapid charging.

Effective thermal management is a key component of a robust EV battery system, contributing significantly to its long-term reliability and safety.

Battery Pack Architecture and Integration

The arrangement and interconnection of individual battery cells within a battery pack significantly impact the overall performance, safety, and efficiency of the EV. Different pack architectures, such as series and parallel configurations, offer varying trade-offs in terms of voltage, current capacity, and safety. The design must carefully consider factors such as cooling mechanisms, electrical connections, and structural integrity. Integrating the battery pack into the vehicle structure needs to be done in a way that optimizes space utilization and minimizes weight, while ensuring structural rigidity and safety.

The complexity of integrating a high-performance battery pack into the vehicle framework requires a holistic approach, considering both the technological aspects and the mechanical requirements of the EV design.