Introduction to Renewable Energy in Automotive Manufacturing

Harnessing Solar Power for Vehicle Production

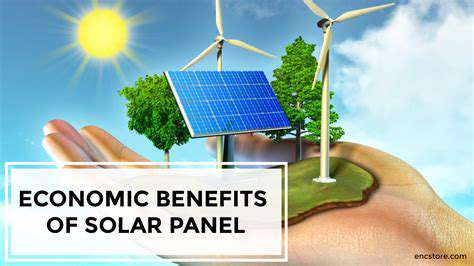

Solar energy, a clean and abundant resource, is increasingly being integrated into automotive manufacturing. Solar panels can power various aspects of the production process, from charging electric vehicle batteries to powering assembly line machinery. This reduces reliance on fossil fuels and lowers carbon emissions throughout the manufacturing lifecycle. The use of solar energy also creates a more sustainable and environmentally friendly manufacturing environment, aligning with global efforts to combat climate change and reduce the industry's overall carbon footprint. By harnessing sunlight, manufacturers can significantly decrease their dependence on traditional energy sources and contribute to a greener future.

Furthermore, advancements in solar technology are making it more cost-effective and efficient. This translates into lower operational costs for manufacturers, making the transition to solar power a financially viable option. The integration of solar energy in automotive production is not just environmentally beneficial; it also represents a smart investment for the long-term sustainability of the industry.

Wind Energy's Role in Electric Vehicle Battery Production

Wind power, another clean and renewable energy source, plays a crucial role in the manufacturing process, particularly in the production of electric vehicle batteries. The energy-intensive processes involved in battery creation require substantial amounts of electricity. Harnessing wind energy to power these processes reduces the reliance on fossil fuels and drastically lowers the carbon footprint associated with battery production. Wind farms can be strategically located near battery manufacturing plants, optimizing energy transfer and reducing transmission losses, thus ensuring a reliable and sustainable energy supply for the entire production chain.

Hydropower and the Future of Automotive Manufacturing

Hydropower, derived from the energy of flowing water, offers a consistent and reliable source of renewable energy that can be integrated into various stages of automotive manufacturing. Large-scale hydropower plants can power entire factories, reducing dependence on fluctuating energy sources and providing a steady flow of electricity for production processes, from metal shaping to final assembly. This consistent energy supply is vital for maintaining production schedules and ensuring the efficient operation of manufacturing facilities.

Geothermal Energy for Heating and Cooling in Factories

Geothermal energy, tapping into the Earth's internal heat, can provide a sustainable solution for heating and cooling automotive manufacturing facilities. This form of renewable energy offers a significant advantage over traditional methods by reducing reliance on fossil fuels for heating and cooling. Geothermal systems can maintain optimal temperatures within the factory, ensuring comfortable working conditions for employees and preventing damage to sensitive machinery due to extreme temperature fluctuations. This reduces energy consumption and operating costs, aligning with broader sustainability goals within the industry.

Bioenergy and Waste Management in Automotive Production

Bioenergy, derived from organic materials, can be used to generate heat and electricity for automotive manufacturing facilities. This process often involves converting organic waste materials, such as agricultural residues or wood chips, into biogas, which can then be used to power generators. Implementing bioenergy solutions not only reduces dependence on fossil fuels but also addresses waste management concerns, creating a closed-loop system where waste is transformed into valuable energy. This innovative approach contributes to a more circular economy, minimizing environmental impact and promoting resource efficiency within the automotive manufacturing sector.

Integrating Solar PV into Automotive Manufacturing Facilities

Harnessing Solar Power for Enhanced Vehicle Efficiency

Integrating solar photovoltaic (PV) panels into automotive designs presents a compelling solution for enhancing vehicle efficiency and reducing reliance on fossil fuels. By capturing solar energy, electric vehicles (EVs) can potentially extend their range and decrease the need for frequent charging, a significant advancement in sustainable transportation. This integration offers a promising pathway toward a more environmentally conscious and energy-independent future for the automotive industry.

The added solar panels can also provide supplemental power for various vehicle systems, contributing to a more holistic approach to energy management. This supplementary energy source can power accessories, improve performance, and ultimately contribute to greater overall vehicle efficiency. This is especially beneficial in hybrid systems where the solar energy can assist the traditional engine or electric motor.

Technological Advancements in Solar PV Integration

Significant technological advancements are paving the way for seamless solar PV integration into vehicles. Researchers are focusing on developing lighter, more durable, and higher-efficiency solar cells that can withstand the rigors of automotive environments. These advancements are crucial for maximizing the energy output while minimizing the additional weight imposed on the vehicle.

Innovative designs for mounting and integrating solar panels into the vehicle's exterior are also emerging, maximizing the available surface area for sunlight capture without compromising aesthetics or structural integrity. This is a critical aspect of the design process, as optimal placement is essential for efficient energy harvesting.

Practical Considerations and Future Outlook

While the potential benefits of solar PV integration are substantial, practical considerations remain. One key challenge is the variability of sunlight availability, which can impact the amount of energy generated. Therefore, sophisticated energy management systems are crucial to optimize energy storage and distribution.

Further research and development are necessary to overcome these challenges and fully realize the potential of solar PV integration in the automotive sector. The future outlook is promising, with significant advancements anticipated in areas like energy storage technology and material science, leading to more efficient and sustainable vehicle designs. The integration of solar PV is poised to revolutionize the automotive industry by reducing dependence on traditional fuel sources and ushering in a new era of environmentally friendly transportation.

Furthermore, the economic viability of solar-powered vehicles hinges on factors such as the cost of solar panels, manufacturing processes, and the overall cost of ownership. These factors need careful consideration and must be addressed for widespread adoption of this technology.

Future Trends and Challenges in Solar PV for Automotive Manufacturing

Emerging Materials and Manufacturing Techniques

The quest for higher efficiency and lower costs in solar PV for automotive applications is driving innovation in materials science. Researchers are exploring novel semiconductor materials beyond silicon, such as perovskites and quantum dots, which hold the potential to significantly boost power conversion efficiency. These materials, often with enhanced light absorption properties, could pave the way for thinner, more flexible solar panels, opening up new design possibilities for integration into vehicle exteriors and even interior components. This shift necessitates advancements in manufacturing techniques, moving beyond traditional silicon wafer production methods to potentially include solution-based approaches for large-scale, cost-effective production of these emerging materials.

Furthermore, advancements in manufacturing techniques are crucial for achieving both high efficiency and scalability. New deposition methods, such as chemical vapor deposition (CVD) and atomic layer deposition (ALD), are being investigated to create high-quality, uniform thin-film solar cells. These techniques offer the potential for precise control over material properties, leading to enhanced performance and reduced manufacturing costs. The development of roll-to-roll printing processes could revolutionize the production of flexible solar panels, making large-scale production more economical and adaptable to various automotive designs.

Integration Challenges and System Optimization

While the potential of solar PV in automotive applications is undeniable, significant challenges remain in integrating these systems seamlessly into existing vehicle designs. The precise placement of solar panels on a car, considering aerodynamic factors, aesthetic concerns, and the need for optimal sunlight exposure, requires careful consideration and innovative design solutions. Integrating solar cells into the vehicle's structural components and achieving robust mechanical stability is critical to ensuring long-term performance and reliability under varying environmental conditions.

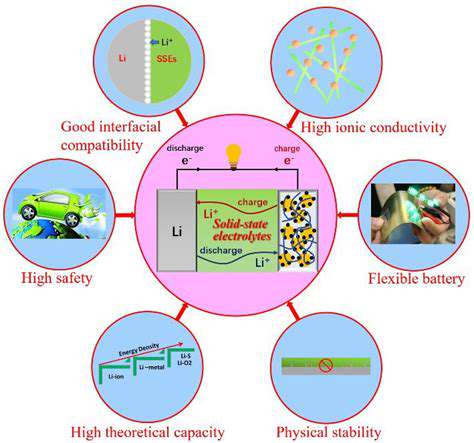

Beyond integration, optimizing the entire system for maximum energy generation and efficient energy storage is crucial. Matching the power output of the solar panels to the vehicle's electrical demands is essential to avoid energy losses. Furthermore, designing robust energy storage systems capable of handling fluctuating solar irradiance and storing excess energy for use during nighttime or low-light conditions is critical for reliable operation. This requires advancements in battery technology, including improved energy density and lifespan, to ensure the system's overall efficiency and practicality for long-term use.

The development of sophisticated control algorithms is also necessary to manage energy flow effectively between the solar panels, batteries, and the vehicle's electrical network. These algorithms will need to account for dynamic conditions, such as varying sunlight intensity and fluctuating energy demands, to ensure continuous and optimal performance. Solving these integration and optimization challenges will be key to realizing the full potential of solar PV in the automotive sector.

The evolving regulatory landscape and public acceptance of solar-powered vehicles are also critical factors to consider. Addressing these challenges will be essential for the widespread adoption of solar PV in the automotive industry.