Introduction to Bio-Based Coatings

Bio-based coatings mark a pivotal shift toward eco-friendly materials in automotive manufacturing. Derived from renewable sources like plant oils and natural polymers, these coatings reduce dependence on fossil fuels. Their biodegradability sets them apart from traditional petroleum-based options, offering a cleaner solution for vehicle finishes while addressing environmental concerns.

Environmental Benefits of Bio-Based Coatings

Beyond their renewable origins, bio-based coatings significantly cut volatile organic compound (VOC) emissions during application. This improvement enhances air quality in production facilities and surrounding communities. Unlike conventional coatings that linger in ecosystems, these biodegradable alternatives break down naturally, easing waste management challenges. The shift also reduces carbon emissions tied to petroleum extraction and processing.

Performance Characteristics of Bio-Based Coatings

Automotive applications demand coatings that withstand UV exposure, weathering, and mechanical stress. Recent formulations now rival traditional coatings in durability while maintaining environmental benefits. Researchers continue refining adhesion properties and chemical resistance to meet industry standards across diverse climates and usage conditions.

Challenges in Implementing Bio-Based Coatings

Current limitations include higher production costs compared to conventional options. Manufacturing processes require optimization to achieve price parity. Performance consistency across different substrates remains an active area of development, with extensive testing needed to validate reliability in all automotive applications.

Research and Development in Bio-Based Coatings

Innovation focuses on hybrid formulations combining bio-based materials with performance-enhancing additives. Academic and industrial collaborations accelerate progress, with several promising prototypes already demonstrating commercial viability. Government incentives further support this transition toward sustainable coating solutions.

Future Outlook for Bio-Based Coatings

The sector anticipates steady growth as production scales and costs decrease. Regulatory pressures and consumer demand for sustainable products will drive adoption, particularly in regions with stringent environmental policies. Within a decade, bio-based coatings could capture significant market share in automotive finishes.

Waterborne Coatings: Minimizing Environmental Impact

Waterborne Coatings: Introduction to the Technology

Water-based formulations revolutionize surface finishing by replacing harmful solvents with water. This fundamental change reduces VOC emissions by 50-80% compared to solvent-based systems, significantly improving air quality in manufacturing environments. The technology has matured to offer application properties comparable to traditional options while meeting stricter environmental regulations.

Environmental Benefits of Waterborne Coatings

The ecological advantages extend beyond reduced VOC emissions. Waterborne systems eliminate the need for complex solvent recovery infrastructure, simplifying waste management while cutting energy consumption. Their cleaner production process aligns with global sustainability goals, particularly in industries facing stringent emissions standards.

Cost-Effectiveness and Efficiency

While initial material costs may be higher, waterborne coatings offer long-term savings through reduced regulatory compliance expenses and waste disposal costs. Improved transfer efficiency during application minimizes material waste, and faster drying times increase production throughput. These factors combine to deliver competitive total cost of ownership.

Performance Characteristics of Waterborne Coatings

Modern formulations achieve exceptional durability, with some products outperforming solvent-based alternatives in weather resistance. Advancements in cross-linking chemistry have closed previous performance gaps, enabling use in demanding automotive applications. The technology now supports diverse aesthetic requirements from high-gloss finishes to textured surfaces.

Application and Drying Processes

Application methods mirror traditional spraying techniques but require adjusted parameters for optimal results. Controlled humidity and temperature during curing prevent common defects, with infrared drying sometimes supplementing conventional methods. Proper training ensures technicians achieve consistent, high-quality finishes.

Safety and Health Considerations

The reduced chemical exposure benefits worker health, particularly in enclosed spaces. Facilities report fewer respiratory complaints and lower insurance premiums after transitioning to waterborne systems. This safety advantage complements the environmental benefits, creating healthier workplaces.

Market Trends and Future Outlook

Adoption rates continue climbing as global regulations tighten. Next-generation formulations will likely incorporate smart functionalities like self-healing properties or color-changing capabilities. The market expects sustained growth as sustainability becomes a competitive differentiator across industries.

Advanced Polymer Technologies and Nanotechnology

Advanced Polymer Synthesis Techniques

Cutting-edge polymerization methods enable precise control over material properties. Techniques like RAFT polymerization allow tuning of molecular architectures for specific automotive applications. Sustainable synthesis routes utilize bio-based monomers and green catalysts, reducing environmental impact without compromising performance.

Polymer Characterization and Analysis

Advanced analytical techniques provide unprecedented insight into polymer structures. Atomic force microscopy reveals nano-scale surface characteristics critical for coating performance, while spectroscopic methods verify chemical composition. These tools ensure materials meet exacting automotive standards before production scaling.

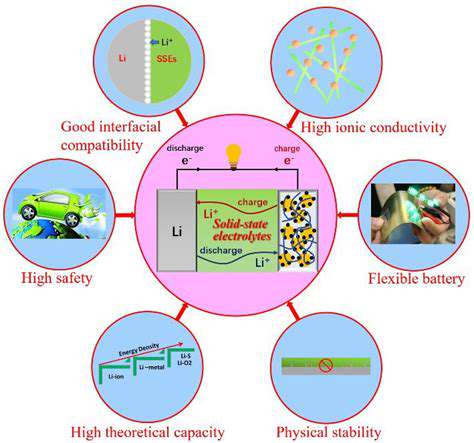

Applications in Emerging Industries

Polymer innovations enable breakthroughs across multiple sectors. In electric vehicles, specialized polymers manage battery thermal regulation and reduce component weight. Aerospace applications benefit from high-temperature resistant formulations that maintain structural integrity under extreme conditions.

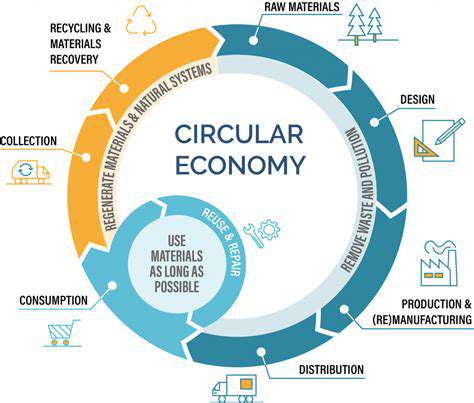

Sustainability and Environmental Impact

The industry prioritizes closed-loop systems for polymer production and recycling. Chemical recycling technologies now recover over 90% of material value from end-of-life products. Bio-derived polymers combined with efficient recycling infrastructure create truly sustainable material cycles for automotive applications.