Introduction to Sustainable Manufacturing in the Automotive Industry

Defining Sustainable Manufacturing

Sustainable manufacturing encompasses a wide range of practices aimed at minimizing the environmental impact of production processes while ensuring economic viability and social responsibility. It's a holistic approach that considers the entire lifecycle of a product, from raw material extraction to end-of-life disposal. This philosophy recognizes the interconnectedness of environmental, economic, and social factors in achieving long-term industrial success. This approach strives to create a system where the production process is not only efficient but also contributes positively to the well-being of people and the planet.

Key components of sustainable manufacturing include resource efficiency, waste reduction, pollution prevention, and the use of renewable energy sources. Implementing these principles helps companies reduce their carbon footprint, conserve resources, and minimize their impact on local ecosystems.

Resource Efficiency and Material Selection

A crucial aspect of sustainable manufacturing is optimizing resource utilization. This involves selecting materials with lower environmental impact, minimizing material waste during production, and finding innovative ways to reuse or recycle byproducts. Prioritizing recycled or renewable materials reduces the reliance on virgin resources, lowering the environmental burden. Effective material selection strategies play a vital role in minimizing the overall environmental footprint of a product.

Using less material overall and employing more efficient production techniques can significantly reduce the amount of waste generated during manufacturing, and contribute to the overall sustainability of the process. This approach also often leads to cost savings in the long run by reducing raw material expenses.

Waste Reduction and Pollution Prevention

Minimizing waste generation throughout the manufacturing process is a cornerstone of sustainable manufacturing. This encompasses strategies for reducing material waste, implementing closed-loop systems for recycling, and developing innovative approaches to waste treatment and disposal. Waste reduction efforts contribute substantially to resource conservation and lower environmental pollution.

Pollution prevention is another key aspect. This involves implementing technologies and processes that minimize or eliminate the release of harmful substances into the air, water, and soil during production. By proactively preventing pollution, manufacturers can significantly reduce their environmental impact and comply with increasingly stringent environmental regulations.

Environmental Impact Assessment and Life Cycle Analysis

Thorough environmental impact assessments (EIAs) are critical for understanding the environmental consequences of manufacturing processes. These assessments help identify potential environmental risks and opportunities for improvement, allowing companies to proactively address environmental concerns. EIAs are instrumental in guiding the development of sustainable manufacturing strategies.

Life cycle analysis (LCA) is another essential tool. LCA examines the environmental impacts of a product throughout its entire life cycle, from raw material extraction to disposal. This comprehensive approach helps identify the most impactful stages of the production process, enabling companies to target their sustainability efforts for maximum effect. LCA helps to pinpoint environmental hotspots in the manufacturing process, allowing for more focused and effective sustainability initiatives.

Social Responsibility and Ethical Considerations

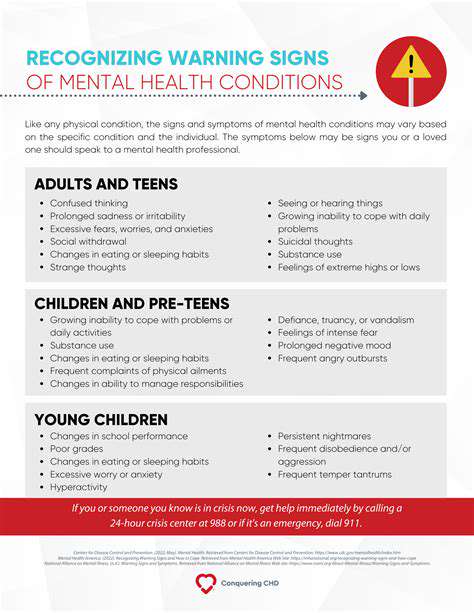

Sustainable manufacturing extends beyond environmental considerations to encompass social responsibility. This includes fair labor practices, safe working conditions, and community engagement. Promoting ethical labor practices ensures that manufacturing operations are conducted in a way that respects human rights and dignity. It also emphasizes the importance of building strong relationships with local communities.

Companies are increasingly recognizing that ethical sourcing and responsible treatment of workers are integral to sustainable manufacturing practices. It's not just about the environment, but also about creating a fair and equitable system for all stakeholders involved in the production process.

Material Selection and Resource Efficiency

Material Selection for Sustainability

Selecting the right materials is crucial for sustainable manufacturing. Consider factors like the material's environmental impact throughout its lifecycle, from extraction and processing to manufacturing, use, and eventual disposal. Choosing recycled or renewable materials whenever possible is a significant step toward minimizing resource depletion and reducing pollution. This involves analyzing the embodied energy of different materials, assessing their recyclability, and evaluating their overall environmental footprint.

Materials with lower embodied energy, meaning they require less energy for extraction and processing, are more sustainable choices. Prioritizing materials with high recyclability rates and design for disassembly also minimize waste and promote circularity in the manufacturing process. A holistic approach to material selection is essential for achieving genuine sustainability in manufacturing.

Resource Efficiency in Manufacturing Processes

Optimizing manufacturing processes for resource efficiency is a vital aspect of sustainable manufacturing. This includes minimizing energy consumption in production, reducing water usage, and controlling the emission of pollutants. Implementing energy-efficient machinery and processes, coupled with waste reduction strategies, is key to minimizing the environmental footprint of manufacturing activities.

Adopting lean manufacturing principles, such as just-in-time inventory management and continuous improvement, can significantly contribute to resource efficiency. Waste reduction strategies, from design for disassembly to material recovery, must be integrated into every stage of the manufacturing process to minimize resource consumption and environmental impacts.

Circular Economy Principles in Material Management

Embracing circular economy principles is paramount for sustainable material management in manufacturing. This involves designing products for recyclability, reusability, and repairability. Implementing closed-loop systems where materials are recovered, reused, and reintroduced into the production cycle minimizes waste and promotes resource conservation.

Supply Chain Considerations

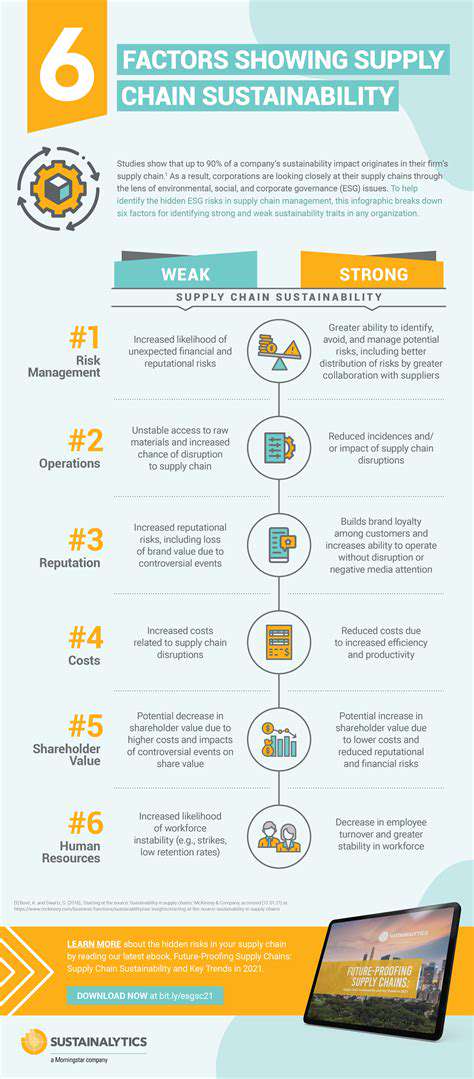

Sustainable material selection and resource efficiency extend beyond the factory walls to encompass the entire supply chain. Scrutinizing the environmental performance of suppliers and promoting ethical sourcing practices are essential. Evaluating the environmental footprint of raw material suppliers, transportation methods, and distribution networks is critical for assessing the overall sustainability of the manufacturing process. Transparent supply chains, where environmental impacts are tracked and managed throughout the process, are vital for building a more sustainable future.

Life Cycle Assessment (LCA) and Material Selection

Conducting a Life Cycle Assessment (LCA) is a powerful tool for evaluating the environmental impact of materials and products throughout their entire lifecycle. LCA methodologies provide a comprehensive understanding of the environmental burdens associated with different materials and manufacturing processes. These data-driven assessments help manufacturers make informed decisions about material selection and process optimization for reduced environmental impact. Understanding the environmental impacts of material sourcing, processing, manufacturing, use, and disposal helps guide choices that minimize the overall ecological footprint.

Waste Reduction and Pollution Control

Waste Minimization Strategies

Implementing waste minimization strategies is crucial for sustainable manufacturing in the automotive industry. This involves a multifaceted approach, encompassing design for disassembly, material selection, and process optimization. Companies should prioritize the use of recycled and renewable materials, reducing the reliance on virgin resources. By minimizing waste generation at each stage of the production process, from component design to manufacturing and assembly, significant environmental benefits can be achieved. This proactive approach not only reduces the volume of waste sent to landfills but also conserves natural resources.

A key component of waste minimization is the concept of design for environment. This involves incorporating environmental considerations into the product design phase, aiming to reduce the environmental impact throughout the product lifecycle. This includes analyzing material choices, manufacturing processes, and end-of-life scenarios. Careful consideration of these factors can lead to significant reductions in waste and pollution generated during the product's entire lifespan, from raw material extraction to disposal.

Pollution Control Measures

Effective pollution control measures are essential to minimize the environmental footprint of automotive manufacturing. Implementing emission control technologies, such as catalytic converters and particulate filters, is crucial for reducing air pollution. Furthermore, stringent regulations regarding wastewater discharge and hazardous material management are necessary. Responsible management of hazardous materials, including proper handling, storage, and disposal, is critical to prevent contamination of the environment and ensure worker safety.

Minimizing the use of harmful substances throughout the manufacturing process is paramount. This includes selecting non-toxic materials whenever possible, implementing efficient waste treatment systems, and ensuring proper disposal procedures for hazardous byproducts. By adopting these measures, automotive manufacturers can significantly reduce their contribution to air and water pollution, promoting a cleaner environment for future generations.

Sustainable Supply Chain Management

Sustainable supply chain management plays a critical role in minimizing the environmental impact of automotive manufacturing. Companies need to evaluate their suppliers' environmental performance and implement strategies to encourage their adoption of sustainable practices. This includes fostering collaboration with suppliers to reduce material waste, improve energy efficiency, and minimize greenhouse gas emissions throughout the entire supply chain. Establishing clear environmental criteria for suppliers is essential for driving positive change and promoting responsible sourcing practices.

Transparency and traceability throughout the supply chain are also vital. This involves tracking the origin and processing of materials to ensure ethical sourcing and to identify potential environmental risks. Building strong relationships with suppliers who share a commitment to sustainability can foster a collaborative environment that encourages continuous improvement and environmental responsibility throughout the entire manufacturing process. This ultimately contributes to a more sustainable and resilient automotive industry.