Recovery of Lithium

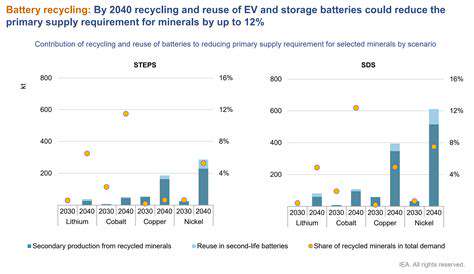

Lithium, a crucial component in EV batteries, is a valuable resource that can be recovered and reused. The process involves separating lithium from other battery components through various chemical and physical techniques. This recovery is essential to minimize the environmental impact of lithium mining and to ensure a sustainable supply chain for future EV production. Properly designed recycling plants can extract high-purity lithium compounds, which can then be used in new battery production, significantly reducing the demand for virgin lithium.

The extraction of lithium from EV batteries is a complex process, requiring specialized equipment and expertise. Carefully controlled chemical reactions and separation techniques are necessary to maximize the yield of pure lithium while minimizing the environmental footprint. This process, while costly, is crucial for the long-term viability of the EV industry and the responsible management of valuable resources.

Recycling of Nickel

Nickel, another critical element in EV batteries, is often recovered alongside other metals. The process typically involves dissolving the battery components in specific acids, followed by techniques like electrolysis to separate the nickel from other materials. The purity of the recovered nickel is a key factor in its reuse in new battery production, and advanced recycling methods are constantly being developed to improve this aspect.

The successful recycling of nickel from EV batteries is vital for reducing reliance on primary nickel sources and ensuring a sustainable supply for the growing electric vehicle market. Efforts are being made to develop more efficient and environmentally friendly methods to recover nickel from spent batteries, further minimizing the environmental impact of battery production and disposal.

Cobalt Recovery Strategies

Cobalt, a valuable metal essential for EV battery performance, is recovered through a multi-step process that often involves leaching the cobalt-containing materials from the battery components. Various chemical treatments are used to separate cobalt from other elements, followed by purification processes to obtain a high-purity cobalt product suitable for reuse. The recovery process needs to be optimized to minimize energy consumption and environmental pollution.

Recovering Manganese and Copper

Manganese and copper, other metals found in EV batteries, are also valuable and can be recovered through similar processes used for other metals. These processes often involve chemical leaching, separation, and purification steps. The recovered materials can be used in various applications, from new battery production to other industrial processes. Efficient recovery methods are essential to reduce the environmental impact of battery disposal and increase the circularity of these valuable materials.

The recovery of manganese and copper is important not only for their reuse in battery production but also for their application in other sectors. The recycling process aims to maximize the recovery of these metals, ensuring their sustainable use in a wide range of applications.

Environmental Impact Considerations

The recovery of precious metals and materials from EV batteries has a significant environmental impact. Properly designed recycling facilities are crucial to minimize the environmental footprint of these operations. This involves careful management of chemical processes, wastewater treatment, and air pollution control. The overall aim is to create a sustainable recycling process that minimizes environmental damage while maximizing resource recovery.

The environmental impact of battery recycling is a critical consideration. Minimizing the use of harmful chemicals, reducing energy consumption, and ensuring the safe disposal of waste materials are paramount to creating a truly sustainable recycling process. Investments in research and development for more environmentally friendly recycling technologies are crucial to achieving this goal.

Economic Benefits and Future Trends

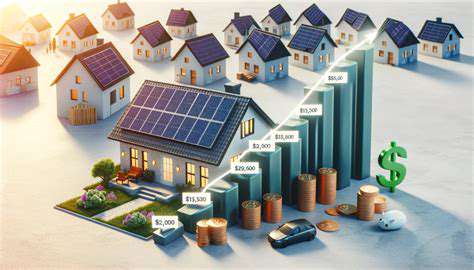

The recovery of precious metals and materials from EV batteries presents substantial economic benefits. The reuse of these materials reduces the demand for primary resources, lowers production costs for new batteries, and creates new economic opportunities in the recycling sector. Government policies and incentives can play a vital role in supporting the growth of the EV battery recycling industry.

Future trends in EV battery recycling will likely involve the development of more efficient and cost-effective recycling processes, the use of advanced technologies like hydrometallurgy and pyrometallurgy, and the integration of recycling into the broader battery supply chain. These advancements are crucial to the long-term sustainability and economic viability of the electric vehicle industry.

Economic Incentives and Policy Support for EV Battery Recycling

Economic Incentives for Sustainable Practices

Economic incentives play a crucial role in encouraging businesses and individuals to adopt sustainable practices. These incentives can range from tax breaks and subsidies to carbon pricing mechanisms and tradable permits. By making sustainable choices more financially attractive, governments can effectively steer the market towards a greener future and encourage innovation in environmentally friendly technologies.

Subsidies for renewable energy sources, for example, can significantly reduce the cost of these technologies, making them more competitive with traditional fossil fuel-based energy sources. This can lead to increased adoption and ultimately, a reduction in greenhouse gas emissions.

Policy Support for Green Technologies

Government policies are essential to fostering a supportive environment for the development and deployment of green technologies. These policies can include research and development grants, streamlined permitting processes, and favorable regulations. Robust policy support is crucial to encourage private sector investment in emerging technologies, accelerating the transition to a low-carbon economy.

Furthermore, policies that mandate the use of energy-efficient appliances or buildings can significantly reduce energy consumption and promote resource conservation. This, in turn, reduces the environmental impact of these sectors.

Carbon Pricing Mechanisms

Carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, are powerful tools for mitigating climate change. These mechanisms put a price on carbon emissions, incentivizing businesses and individuals to reduce their carbon footprint. By internalizing the environmental costs of pollution, carbon pricing creates a market-based solution to the climate crisis. This economic approach can be more effective than traditional regulatory approaches in encouraging broad-based change.

Investment in Green Infrastructure

Significant investment in green infrastructure is necessary to support the transition to a sustainable economy. This includes investments in public transportation, renewable energy grids, and sustainable urban planning. This infrastructure not only improves the environment but also creates jobs and boosts economic growth. Sustainable infrastructure projects can also improve public health by reducing air pollution and promoting healthier lifestyles.

Promoting Sustainable Consumption and Production

Encouraging sustainable consumption and production patterns is vital for achieving long-term environmental goals. Policies that promote recycling, reuse, and extended producer responsibility can reduce waste and resource depletion. Education and awareness campaigns can further encourage consumers to make environmentally conscious choices in their daily lives. This shift in consumer behavior, supported by appropriate policies, is a key component of a successful transition to a sustainable future.