How to Choose the Right Replacement Filter

Understanding Your Needs

Choosing the right replacement air filter for your car's cabin air system is crucial for maintaining a healthy and comfortable driving experience. Understanding your vehicle's specific needs, including the type of air filter it requires (e.g., cabin, engine), is the first step. Different models and years of vehicles may have unique filter specifications, so consulting your owner's manual or contacting a reputable auto parts retailer is essential to ensure compatibility. Knowing your car's make, model, and year is vital for proper selection.

Consider the type of environment you primarily drive in. If you frequently drive through areas with high pollen counts, dust, or other airborne pollutants, a higher-quality filter with more advanced filtration capabilities might be beneficial. This can significantly improve the air quality inside your car, making your commute more pleasant and potentially reducing allergies.

Comparing Filter Types and Features

There are various types of cabin air filters available, each with unique features and benefits. Some filters focus on trapping larger particles, while others excel at capturing microscopic pollutants. Understanding these differences is key to selecting the right filter for your needs. For example, some filters are designed to effectively block pollen and mold spores, while others provide enhanced protection against dust mites. Thoroughly researching different filter types and their specifications is essential to making an informed decision.

Beyond particle filtration, consider features such as activated carbon. Activated carbon filters can help absorb odors and gases, improving the overall air quality and eliminating unpleasant smells inside your car. This feature is particularly helpful for vehicles that may experience lingering smells from road trips or other environmental factors.

Considering Budget and Quality

Budget is often a significant factor when making purchasing decisions. However, it's important to strike a balance between cost and quality. While budget-friendly options are available, investing in a higher-quality filter can offer long-term benefits. High-quality filters often provide superior filtration capabilities, lasting longer, and effectively trapping a broader range of contaminants. This can lead to a more comfortable and healthier driving experience over time, potentially reducing the need for frequent filter replacements.

Researching reviews and comparing prices from different retailers can help you identify the best value for your money. Consider the long-term cost savings associated with a higher-quality filter that provides superior protection and potentially lasts longer than a less expensive alternative. This approach can save you money in the long run by reducing the frequency of filter replacements and maintaining better overall air quality.

Installation and Maintenance

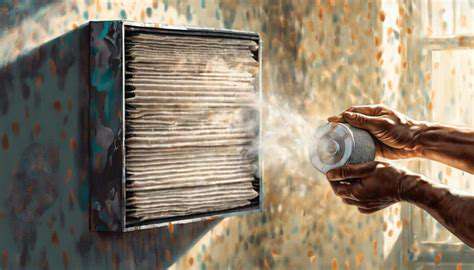

Proper installation of the replacement filter is crucial for optimal performance. Incorrect installation can compromise the filter's effectiveness and potentially lead to airflow issues or other problems. Following the manufacturer's instructions carefully during installation is vital to ensure proper functionality. Referencing the installation guide provided with your new filter or online resources can provide detailed steps and guidance.

Regular maintenance is also key. Replacing your cabin air filter on a schedule recommended by your vehicle's manufacturer is essential. This ensures consistent air quality and prevents the buildup of contaminants, which can negatively impact your driving experience. Failing to maintain your filter regularly can lead to reduced airflow, decreased effectiveness, and potentially contribute to the development of health issues related to poor air quality. Scheduling filter replacements as part of your regular car maintenance can prevent these issues.

The Step-by-Step Replacement Process

Disassembly and Preparation

The initial step involves carefully disassembling the existing component. This meticulous process requires precision and attention to detail to ensure no damage occurs to the surrounding parts. Proper documentation of the disassembly process is crucial for accurate reassembly later. Detailed photographs and diagrams are highly recommended for complex components. This documentation will serve as a valuable guide during the reassembly phase.

Once disassembled, thoroughly inspect each part for any signs of wear, damage, or other issues. Cleaning the parts with appropriate solvents will remove any contaminants or debris that could hinder the proper functioning of the new component. This cleaning step is essential to guarantee a seamless integration of the replacement part.

Component Selection

Selecting the correct replacement component is paramount to ensure compatibility and optimal performance. Consult the manufacturer's specifications or a qualified technician to identify the precise part number required for your specific application. Incorrect component selection can lead to significant performance issues or even damage to other components. Always prioritize quality components from reputable suppliers.

Tools and Materials

Gathering the necessary tools and materials is critical for a smooth and efficient replacement process. Ensure you have the right tools to safely and effectively handle the component. This might include screwdrivers, pliers, and specialized tools depending on the specific component. Having all required materials, such as lubricants or adhesives, readily available will prevent delays.

Checking the availability of all necessary tools and materials before starting the replacement process is crucial. This will prevent delays and ensure a smooth and efficient replacement process. A well-stocked toolbox will significantly reduce the chances of issues arising during the replacement procedure.

Installation Procedure

Following the pre-prepared instructions, carefully install the new component. Pay close attention to alignment and ensure all connections are secure. Improper installation can lead to malfunctions or even safety hazards. Thoroughly examine the installation to ensure everything is correctly positioned and functioning as expected. Adhering to the manufacturer's guidelines is essential to avoid potential problems.

Testing and Verification

After installation, thoroughly test the functionality of the replaced component to ensure it operates correctly. This testing should encompass all expected functionalities and should be performed in a controlled environment. Any discrepancies or malfunctions should be addressed immediately to prevent further issues. This testing phase is crucial to verify the successful completion of the replacement process.

Documenting the test results and any observed issues is critical for future troubleshooting or maintenance. This documentation serves as a valuable record of the replacement procedure and its outcome. It also helps in identifying any potential recurring issues in the future.