Key Pillars of Sustainable Supply Chain Management in Automotive

Ethical Sourcing and Labor Practices

A crucial pillar of sustainable supply chain management in the automotive industry involves prioritizing ethical sourcing and fair labor practices throughout the entire value chain. This encompasses ensuring that materials are sourced responsibly, minimizing environmental impact during extraction and transportation, and guaranteeing safe and equitable working conditions for all employees involved in manufacturing and assembly. Companies must actively engage with suppliers to verify compliance with international labor standards and human rights principles. This commitment extends beyond simply adhering to legal requirements; it necessitates a proactive approach to identifying and mitigating potential risks, fostering transparency, and promoting a culture of respect and dignity within the supply chain.

Implementing robust due diligence processes, including independent audits and regular monitoring, is essential to ensure that ethical standards are consistently met. Furthermore, fostering strong relationships with suppliers, providing them with training and resources, and promoting open communication channels are vital for building a sustainable and ethical supply chain. This proactive approach not only minimizes the risk of reputational damage but also contributes to a more equitable and responsible global automotive industry.

Environmental Stewardship and Sustainability

Environmental sustainability is paramount in modern automotive supply chains. Reducing the environmental footprint throughout the entire lifecycle of vehicles, from material sourcing to manufacturing, use, and end-of-life management, is critical. This involves minimizing resource consumption, reducing waste generation, and mitigating greenhouse gas emissions. Companies must adopt environmentally friendly manufacturing processes, utilize recycled and renewable materials, and implement strategies to minimize energy consumption during production.

Embracing circular economy principles, such as designing for disassembly and reuse, is also essential. This means developing vehicles that can be easily dismantled and their components recycled or repurposed, minimizing the environmental impact of end-of-life vehicle disposal. Furthermore, promoting energy-efficient transportation methods throughout the supply chain, from raw material extraction to delivery of finished products, is crucial for achieving environmental sustainability.

Supply Chain Resilience and Risk Management

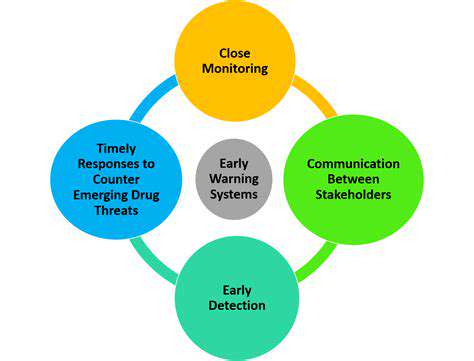

Building a resilient and adaptable supply chain is vital for navigating the uncertainties and disruptions that can occur in today's globalized world. This includes diversifying supplier networks, developing contingency plans to address potential disruptions, and proactively monitoring geopolitical risks, economic fluctuations, and natural disasters. Companies must anticipate potential bottlenecks and develop strategies to mitigate their impact on production and delivery.

Strengthening relationships with key suppliers, fostering collaboration, and promoting transparency across the chain are critical for building resilience. Investing in advanced technologies and data analytics to forecast and predict potential disruptions can also significantly enhance the supply chain's ability to adapt and respond effectively to unexpected events. A robust risk management framework, incorporating scenario planning and stress testing, is essential for safeguarding against potential disruptions and maintaining operational continuity.

Innovation and Technological Advancements

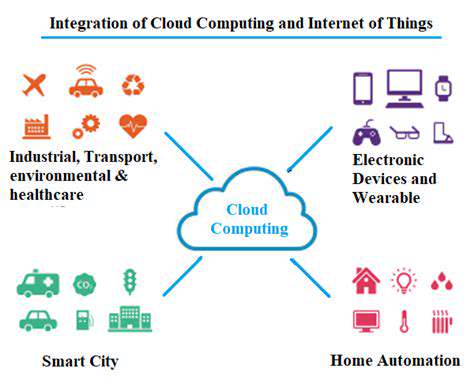

Embracing innovation and leveraging technological advancements is crucial for optimizing and streamlining the automotive supply chain. Adopting digital technologies, such as blockchain, AI, and IoT, can enhance transparency, traceability, and efficiency throughout the value chain. This includes tracking materials, monitoring production processes, and optimizing logistics and delivery. Implementing advanced analytics to predict demand and optimize inventory management can also significantly reduce costs and waste.

Furthermore, fostering collaboration with technology providers and research institutions to develop sustainable materials and manufacturing processes is essential. Investing in research and development for electric vehicles, autonomous driving systems, and other innovative automotive technologies can create new opportunities and contribute to a more sustainable future. This proactive approach to innovation can position companies for growth and competitiveness in a rapidly evolving industry.

Transparency and Traceability

Promoting transparency and traceability throughout the automotive supply chain is essential for building trust and demonstrating accountability. This involves providing clear and accessible information about the origin of materials, manufacturing processes, and the labor practices employed. Implementing technologies, such as blockchain, can enhance transparency and traceability, allowing stakeholders to track products from raw material extraction to the final delivery of the vehicle.

Building trust with consumers and stakeholders requires demonstrating a commitment to ethical sourcing, environmental responsibility, and safe working conditions. Open communication and readily available information about the supply chain can foster greater confidence and support for sustainable practices. This transparency also enables companies to address potential issues quickly and effectively, promoting greater accountability and responsible business practices.