Early Attempts and Limitations

Electric vehicle (EV) battery development traces its roots to an era predating modern lithium-ion technology. Initial experiments utilized diverse chemical compositions, with lead-acid batteries emerging as an early favorite. These primitive power sources delivered disappointing energy capacity, forcing vehicles to carry excessive weight while offering minimal range. Such technological constraints severely limited the practicality of electric transportation during its formative years.

The supporting infrastructure for these early EVs proved equally problematic. Charging stations were scarce and technologically primitive, further confining electric vehicles to specialized roles rather than mainstream transportation solutions.

The Rise of Nickel-Cadmium and Nickel-Metal Hydride

Technological progress introduced nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) batteries as successors to lead-acid technology. These newer formulations demonstrated measurable improvements in both energy storage capacity and operational lifespan. However, they still failed to meet the demanding requirements for mass-market electric vehicles, particularly in charging speed and durability metrics.

Despite representing technological advancement, these battery systems remained prohibitively heavy and energy-inefficient for practical, long-distance electric vehicles. The search for superior energy storage solutions continued unabated.

The Dawn of Lithium-Ion: A Paradigm Shift

Lithium-ion (Li-ion) technology emerged as a game-changing innovation in EV development. With energy density far surpassing previous technologies, these batteries enabled vehicle designs that combined lighter weight with extended operational range. This breakthrough finally made electric vehicles a viable alternative to traditional gasoline-powered transportation.

Continuous refinement of Li-ion technology has propelled the rapid evolution of both electric vehicles and their supporting infrastructure. This progress reflects both scientific achievement and growing societal commitment to sustainable mobility solutions.

Key Considerations and Future Directions

The evolution of EV batteries represents not a straight path but rather a complex journey of experimentation, adaptation, and incremental improvement. Appreciating the historical context of early battery technologies provides valuable perspective on current achievements and future possibilities.

Contemporary research focuses on three critical areas: enhancing safety protocols, reducing charging durations, and extending operational lifespan. These technological advances will prove essential for making electric vehicles more practical and accessible, ultimately supporting the transition to sustainable transportation systems. Additionally, scientists continue exploring battery chemistries that may one day surpass lithium-ion technology.

Lithium-ion Dominance: Chemistry, Materials, and Manufacturing

Lithium-ion Battery Chemistry: A Deep Dive

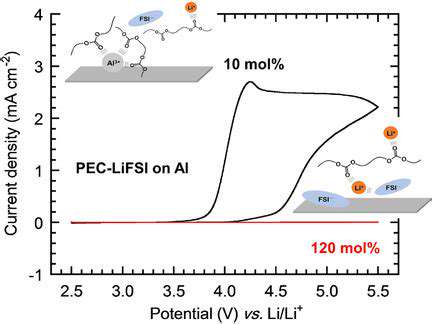

The revolutionary impact of lithium-ion batteries across multiple industries stems from their unique electrochemical properties. The movement of lithium ions between electrodes during charge and discharge cycles creates an exceptionally efficient energy storage mechanism with impressive density. This process involves complex intercalation chemistry, typically using lithium cobalt oxide (LiCoO2) or nickel-rich compounds as electrode materials.

Material selection critically influences battery performance characteristics. The careful balance between anode, cathode, and electrolyte components determines voltage output, storage capacity, and operational longevity. Mastering these material relationships remains fundamental to addressing current limitations in safety, cost, and performance.

Factors Driving Lithium-ion Battery Adoption

Several compelling advantages have cemented lithium-ion technology's market dominance. The high energy density enables compact devices with extended operational duration. Equally important are the technology's reliable performance across temperature variations and its respectable service life.

Parallel improvements in manufacturing techniques and materials science have gradually reduced production costs, facilitating broader application beyond consumer electronics into electric vehicles and grid-scale energy storage solutions.

Challenges and Future Directions

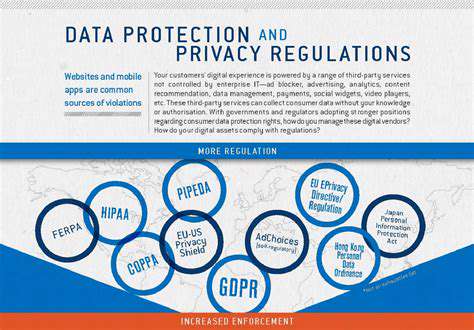

Despite their widespread adoption, lithium-ion batteries present several unresolved challenges. Geopolitical concerns and finite resource availability raise questions about long-term material supply chains. Developing safer battery architectures, particularly for high-energy applications, remains an urgent research priority.

Future innovation focuses on alternative chemistries with improved performance metrics and sustainability profiles. This includes investigating novel electrode materials, advanced electrolytes, and innovative structural designs. Such research initiatives aim to transcend current technological limitations and develop next-generation energy storage solutions.

Safety Considerations in Lithium-ion Batteries

The impressive energy density of lithium-ion batteries comes with inherent safety considerations. Thermal runaway presents the most significant risk, potentially leading to dangerous overheating scenarios. Robust engineering solutions and comprehensive safety protocols are essential to mitigate these risks in both consumer and industrial applications.

Cost and Sustainability Concerns

Material costs represent a substantial portion of lithium-ion battery production expenses, particularly for large-scale implementations. Developing more sustainable material sourcing strategies is becoming increasingly crucial for reducing the environmental impact of battery manufacturing.

As electric vehicle adoption accelerates, the industry faces mounting pressure to establish environmentally responsible production practices. Current research explores methods to minimize ecological damage while maintaining or improving battery performance characteristics.

The Future of EV Batteries: Sustainability and Beyond

Sustainable Materials and Manufacturing

The evolution of electric vehicle batteries increasingly prioritizes sustainable material sourcing and production methods. Current lithium-ion technology depends heavily on materials like cobalt, often extracted under ethically questionable conditions. Transitioning to more abundant alternatives, including manganese-based chemistries, requires extensive research to ensure comparable performance metrics. This shift must coincide with manufacturing innovations that reduce waste generation and energy consumption throughout the production lifecycle.

Advanced recycling methodologies will play a pivotal role in establishing a circular economy for battery materials. Effective recovery processes can significantly reduce reliance on virgin resources while minimizing environmental contamination from battery disposal. Comprehensive lifecycle analysis tools are becoming essential for evaluating and improving the sustainability credentials of emerging battery technologies.

Enhanced Battery Performance and Lifespan

Next-generation EV batteries must deliver measurable improvements in both performance and durability. Increasing energy density remains a primary focus, enabling extended range capabilities that alleviate consumer concerns. Simultaneously, research into novel electrode architectures and electrolyte formulations aims to dramatically reduce charging times. Advanced battery management systems incorporating sophisticated thermal regulation will prove critical for maximizing operational lifespan and ensuring long-term reliability.

Safety enhancements represent another crucial development area. Innovations in cell design and protective systems aim to virtually eliminate thermal runaway risks, building consumer confidence in electric vehicle technology.

Beyond the EV: Applications in Stationary Storage and Grid Integration

The potential applications of advanced battery technology extend far beyond automotive uses. Large-scale energy storage systems utilizing EV battery technology could revolutionize power grid management. Such installations would provide essential stability for renewable energy networks, compensating for the intermittent nature of solar and wind generation. This integration promises to transform electrical infrastructure, enabling more efficient energy distribution and consumption patterns.

Continued innovation in battery chemistry and system design may unlock additional applications across various industries. Realizing this potential will require coordinated efforts among researchers, manufacturers, and policymakers to ensure responsible technological development and deployment strategies.