Waterborne Coatings: A Sustainable Alternative

Waterborne Coatings: An Overview

Waterborne coatings are a type of paint or varnish that uses water as a primary solvent instead of harmful organic solvents. This crucial difference makes them a significantly more environmentally friendly option compared to traditional solvent-based coatings. Their reduced VOC emissions contribute to cleaner air quality, and their lower toxicity poses fewer risks to human health. These coatings are becoming increasingly popular due to their sustainability benefits.

Environmental Advantages of Waterborne Coatings

The shift towards waterborne coatings is a direct response to the growing awareness of the environmental impact of traditional paints. Waterborne coatings significantly reduce volatile organic compound (VOC) emissions, a major contributor to air pollution. This reduction is especially important in urban areas and industrial settings where air quality is a primary concern.

Furthermore, the water-based nature of these coatings minimizes the risk of hazardous waste disposal. This is a significant advantage for both manufacturers and end-users, making them a more sustainable choice throughout their lifecycle.

Performance Characteristics of Waterborne Coatings

While sustainability is a key driver, waterborne coatings also offer excellent performance characteristics. They often exhibit comparable durability and aesthetic qualities to solvent-based coatings, providing a high-quality finish for a wide range of applications. However, specific formulations and application methods might require adjustments to achieve optimal results.

Application and Drying Times

Applying waterborne coatings usually involves specific techniques to ensure proper drying and adhesion. The water content necessitates careful consideration of application methods and drying times to avoid defects or uneven surfaces. Adjusting application rates and drying conditions is crucial for achieving the desired finish and minimizing issues like sagging or uneven coverage.

Cost-Effectiveness and Market Trends

Despite initial investment costs, waterborne coatings often prove cost-effective in the long run due to reduced waste disposal costs and potential energy savings. The growing demand for sustainable products is driving significant advancements and innovation in waterborne coating technology, leading to a wider range of options and improved performance characteristics.

Future of Waterborne Coatings

The future of waterborne coatings looks promising, with ongoing research and development focusing on enhancing performance, expanding applications, and further reducing environmental impact. Innovation in formulations, coupled with improved application methods, will likely lead to even more durable and versatile waterborne products. This ongoing development promises to make waterborne coatings an increasingly attractive and sustainable choice for various industries.

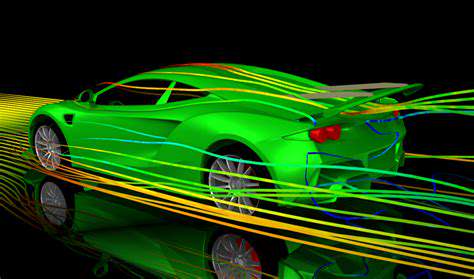

Specific Applications of Waterborne Coatings

Waterborne coatings find applications in diverse sectors, including automotive finishes, marine coatings, industrial paints, and architectural coatings. The versatility of these coatings allows for customization for specific needs and environments, making them ideal for a variety of construction and industrial projects. From protecting infrastructure to enhancing aesthetic appeal, waterborne coatings are an important part of modern design and construction.

Sustainable Manufacturing Practices Beyond Coatings

Minimizing Environmental Impact

Sustainable manufacturing practices are crucial for mitigating the environmental footprint of industrial processes. Reducing waste generation and emissions is paramount, requiring careful consideration of every stage of production, from raw material sourcing to product disposal. This includes implementing closed-loop systems to maximize resource utilization and minimize the need for virgin materials, which can significantly reduce environmental strain.

Implementing energy-efficient technologies and processes is another critical aspect of minimizing environmental impact. Companies can achieve significant reductions in energy consumption by adopting renewable energy sources, upgrading to more efficient machinery, and optimizing production processes to minimize energy waste. These measures not only protect the environment but also contribute to cost savings in the long run.

Resource Efficiency and Circularity

Sustainable manufacturing emphasizes the efficient use of resources throughout the production lifecycle. This includes minimizing material waste by optimizing designs, using recycled materials, and implementing strategies for product reuse and recycling. By embracing circular economy principles, manufacturers can move away from a linear take-make-dispose model and transition to a more sustainable and restorative approach.

Adopting a circular economy mindset involves designing products for disassembly and reuse, promoting the sharing and leasing of products, and establishing robust recycling and recovery systems. These strategies are essential for minimizing resource depletion and promoting a more sustainable future for manufacturing.

Waste Reduction and Management

Minimizing waste generation at every stage of production is a key component of sustainable manufacturing. This includes implementing waste reduction strategies, such as optimizing production processes to eliminate unnecessary steps and materials, and utilizing innovative technologies and materials to reduce waste output. Waste reduction not only protects the environment but also lowers operational costs.

Effective waste management systems must be implemented to ensure that any unavoidable waste is handled responsibly. This involves proper segregation, recycling, and disposal of waste materials. Proper waste management practices minimize environmental contamination and safeguard human health, contributing to a cleaner and healthier environment.

Employee Well-being and Safety

Sustainable manufacturing extends beyond environmental considerations to encompass the well-being and safety of employees. Creating a safe and healthy work environment is essential for maintaining a productive workforce. Investing in employee safety training, providing adequate protective equipment, and implementing ergonomic designs are crucial elements of a sustainable manufacturing approach.

Supply Chain Sustainability

Sustainable manufacturing practices extend beyond the factory walls to encompass the entire supply chain. Companies must evaluate and select suppliers that align with their sustainability goals, ensuring that materials are sourced responsibly and ethically. Promoting transparency and traceability throughout the supply chain is vital to understand and mitigate potential environmental and social risks associated with the sourcing of materials and components.

This requires implementing robust due diligence processes, engaging with suppliers to improve their sustainability practices, and monitoring the entire supply chain to ensure compliance with environmental and social standards. These efforts contribute to a more sustainable and responsible manufacturing ecosystem.