Aerodynamic Principles

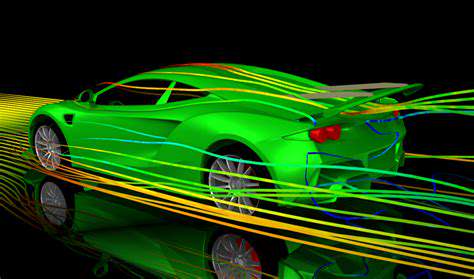

Aerodynamics, the study of how air flows around objects, is crucial for optimizing the efficiency of various systems, from aircraft to automobiles. Understanding the principles of air pressure, lift, and drag is fundamental to achieving optimal performance. This knowledge allows engineers to design shapes and surfaces that minimize resistance and maximize the forces that propel vehicles and other objects through the air.

Various aerodynamic forces, such as lift and drag, interact to influence the overall performance of a system. Understanding these forces and how they are affected by factors like shape, surface area, and velocity enables engineers to design systems that are both efficient and effective.

Shape Optimization

The shape of an object plays a critical role in its aerodynamic performance. Streamlined shapes, minimizing sharp edges and corners, are generally preferred for reducing drag and maximizing lift. These shapes create smoother airflow, leading to reduced energy loss and increased efficiency. This is a key principle in designing efficient vehicles and structures.

Surface Roughness

Surface roughness significantly impacts aerodynamic performance. Smooth surfaces allow for smoother airflow, minimizing turbulence and drag. Rough surfaces, on the other hand, create turbulence and increase drag, reducing efficiency.

Careful consideration of surface finish is critical for achieving optimal aerodynamic performance in various applications.

Importance of Airflow

Understanding how air flows around an object is essential. Predicting and controlling airflow patterns is key to optimizing lift and reducing drag, leading to increased efficiency and performance. Advanced computational fluid dynamics (CFD) techniques allow engineers to simulate and analyze airflow around complex shapes, providing valuable insights for design optimization.

Applications in Transportation

Aerodynamics is extensively used in the design of vehicles, such as cars, airplanes, and trains. Optimizing the aerodynamic design of these vehicles significantly impacts fuel economy and performance. By minimizing drag and maximizing lift, manufacturers can reduce fuel consumption and improve speed and handling.

This translates into reduced emissions and improved overall efficiency in transportation systems.

Beyond Vehicles

The principles of aerodynamics extend beyond the realm of transportation. They are also crucial in the design of buildings, sports equipment, and even in the development of specialized industrial tools. Proper aerodynamic design can significantly improve the performance and efficiency of these diverse applications.

Consideration of airflow patterns is essential for achieving optimal results in various non-transport fields.

Beyond the Engine: Integrating Electrification and Hybrid Technologies

Electrification's Impact on Vehicle Architecture

Integrating electric motors and batteries necessitates a fundamental shift in vehicle architecture. No longer are traditional combustion engine compartments the sole focus. This necessitates careful consideration of battery placement, thermal management systems, and the overall weight distribution of the vehicle. Efficient packaging and integration of these new components are critical to maintaining the desired performance and handling characteristics, while also minimizing the added weight and maximizing passenger space. The design challenges are significant, demanding innovative solutions and advanced engineering practices to achieve optimal results.

Furthermore, the shift toward electrification directly impacts the vehicle's mechanical systems, including the suspension, braking, and steering. Engineers must recalibrate these systems to account for the different torque characteristics and power delivery profiles of electric motors. This necessitates a re-evaluation of existing design principles and the development of new solutions that cater specifically to the demands of electrified vehicles. The goal is to maintain or even enhance the driving experience while optimizing the energy efficiency and performance of the electrified powertrain.

Hybrid Systems: A Spectrum of Solutions

Hybrid vehicle technology presents a spectrum of options, ranging from mild hybrids that supplement the engine with small electric motors to plug-in hybrids that offer extended electric-only range. Each configuration presents unique design and engineering challenges. Understanding the specific requirements of each hybrid configuration is crucial for optimizing performance, efficiency, and the overall driving experience. Different hybrid systems also impact the vehicle's charging infrastructure, driving dynamics, and the complexity of the vehicle's control systems.

The choice of hybrid system depends on a variety of factors, including the target market, the desired level of fuel efficiency, and the required range of electric-only operation. Manufacturers must carefully weigh these factors to develop hybrid systems that address the specific needs of their target customers. For example, mild hybrid systems might be suitable for improving fuel efficiency in vehicles with relatively low driving distances, while plug-in hybrid systems can offer a more significant reduction in emissions and a greater electric-only range, making them more suitable for drivers who frequently require longer distances of electric-only travel. The range of possible solutions within the hybrid domain is vast and ever-evolving.

Sustainable Design Considerations for Electrification

Sustainable design principles are paramount when integrating electrification and hybrid technologies. Material selection plays a crucial role. Lightweight materials, recycled components, and the use of sustainable manufacturing processes are key to reducing the environmental footprint of the vehicle throughout its lifecycle. The entire supply chain, from raw material extraction to vehicle disposal, must be considered to ensure a genuinely sustainable product. This includes optimizing battery materials and ensuring the responsible sourcing and recycling of critical components.

Beyond materials, energy efficiency and waste reduction are essential components of a sustainable design strategy. Minimizing energy consumption during both the manufacturing process and the vehicle's operation is crucial. Optimizing the vehicle's aerodynamic design, reducing friction, and implementing regenerative braking systems are all critical steps in achieving a more sustainable product. Furthermore, the design should anticipate future developments and innovations in energy storage, aiming to ensure the long-term sustainability of the vehicle and its components. The entire process requires careful consideration of environmental impact at every stage of the product lifecycle.