Optimizing Material Recovery Through Advanced Technologies

Material Selection and Sourcing

Strategic material selection serves as the backbone of any successful recovery initiative. Deep knowledge of material properties and behaviors during processing separates effective recycling programs from ineffective ones. Facilities must prioritize materials with known recyclability while actively working to eliminate contaminants that disrupt operations. Responsible sourcing goes hand-in-hand with this approach, requiring coordinated efforts across procurement and logistics teams to maintain consistent material quality.

Modern tracking solutions now enable unprecedented visibility throughout material lifecycles. By implementing comprehensive traceability systems, operations can monitor materials from initial procurement through final processing. This granular tracking capability helps identify inefficiencies and reveals opportunities for process refinement that directly impact recovery outcomes.

Process Optimization Strategies

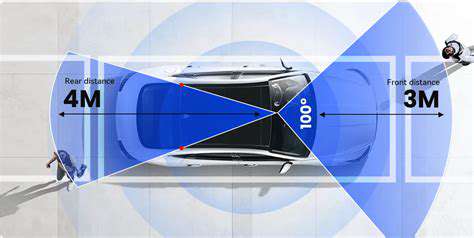

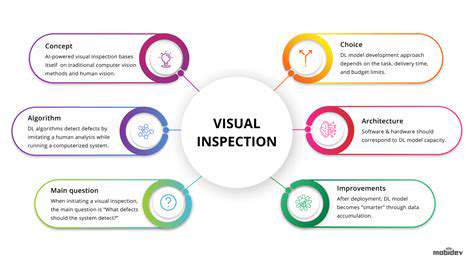

Today's sorting facilities employ sophisticated technologies that revolutionize material separation. Optical sorting systems combined with intelligent magnetic separators achieve precision that manual methods cannot match. These technological solutions deliver measurable improvements in both material purity and recovery volumes. The resulting output meets higher quality standards demanded by manufacturers seeking recycled content.

Processing parameters require constant evaluation to maximize efficiency. Facilities conduct ongoing testing of temperature ranges, pressure settings, and throughput rates to identify optimal operating conditions. This empirical approach ensures equipment performs at peak capability while minimizing energy consumption and operational costs.

Waste Stream Characterization and Analysis

Successful recovery programs begin with comprehensive waste audits. Detailed composition analysis reveals the exact makeup of incoming material streams. Without this fundamental understanding, facilities operate blindly, unable to tailor processes to specific material characteristics. Regular sampling and analysis establish baseline metrics that drive continuous improvement.

Historical waste data provides invaluable insights into evolving material trends. Analytical tools detect patterns in contamination levels, material mix variations, and seasonal fluctuations. Operations teams leverage these findings to adjust sorting parameters, equipment configurations, and processing techniques in real-time.

Technological Advancements in Recycling

The recycling sector continues to benefit from remarkable technological progress. Next-generation sorting systems now incorporate artificial intelligence to identify and separate materials with unprecedented accuracy. These innovations dramatically increase both the volume and quality of recovered materials while reducing processing time. Chemical recycling breakthroughs meanwhile unlock new possibilities for materials previously considered non-recyclable.

Material science innovations contribute significantly to circular economy goals. Researchers continue developing polymers and composites designed specifically for multiple lifecycles. These engineered materials maintain performance characteristics while offering simplified disassembly and purification processes compared to conventional alternatives.

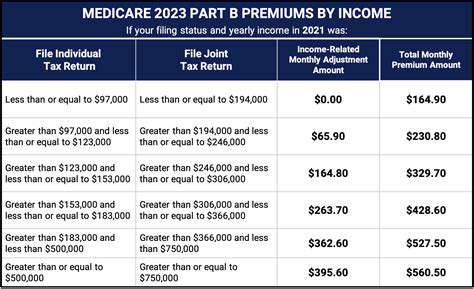

Economic and Policy Considerations

Financial viability remains critical for sustainable recovery operations. Comprehensive cost analysis must account for collection logistics, processing expenses, and final product market values. Successful programs balance these economic factors to create self-sustaining operations rather than relying on continuous subsidies.

Policy frameworks significantly influence recovery rates across industries. Forward-thinking legislation like extended producer responsibility shifts accountability to manufacturers, creating powerful incentives for design improvements. Tax incentives and procurement preferences for recycled content further stimulate market demand, completing the circular economy loop.

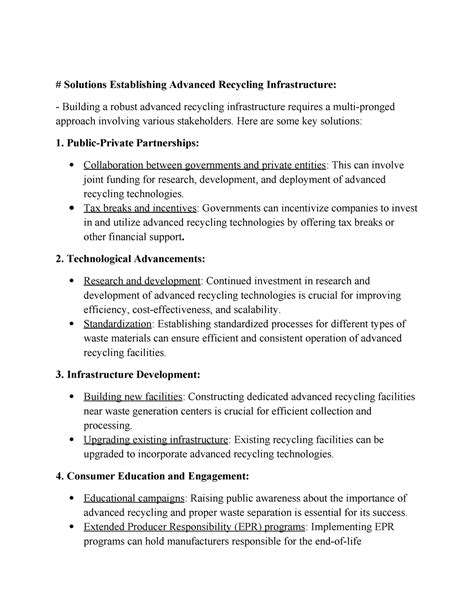

Establishing Robust Recycling Infrastructure

Streamlining Collection and Sorting

Efficient collection networks form the critical first link in the recycling chain. Strategically positioned collection points with clearly marked containers dramatically improve participation rates and material quality. Municipalities see greatest success when implementing color-coded systems with standardized signage that eliminates sorting confusion.

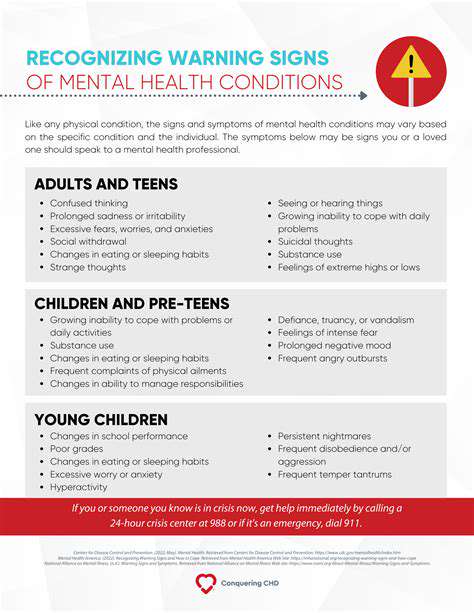

Frontline sorting operations benefit tremendously from ongoing public education. Interactive sorting guides, instructional videos, and community workshops all contribute to cleaner material streams. When residents understand exactly what happens to their recyclables, they become more diligent about proper preparation and sorting.

Enhancing Material Recovery

Modern recovery facilities now deploy sensor-based sorting technologies that outperform manual methods. These advanced systems can distinguish between similar-looking materials based on chemical composition rather than just visual characteristics. The resulting output achieves purity levels that command premium pricing in secondary material markets.

Quality control protocols must be implemented at multiple process checkpoints. Automated screening systems detect and remove contaminants before they compromise entire material batches. This vigilant approach maintains the integrity of recycled materials while reducing downstream processing issues.

Investing in Infrastructure

Comprehensive recycling infrastructure requires coordinated investment across multiple sectors. Material recovery facilities need adequate space for receiving, sorting, and baling operations. Without proper infrastructure scaling, systems become overwhelmed during peak collection periods, creating bottlenecks that undermine efficiency.

Forward-looking facilities design flexibility into their infrastructure plans. Modular equipment configurations allow for technology upgrades without complete system overhauls. This adaptive approach ensures infrastructure remains relevant as material streams and processing technologies evolve.

Community Engagement and Education

Successful recycling programs recognize education as an ongoing process rather than a one-time initiative. Multi-generational outreach that combines school programs with adult education creates lasting behavioral change. Digital platforms now enable personalized feedback to residents about their recycling habits, creating powerful reinforcement mechanisms.

Hands-on learning experiences produce the most impactful results. Facility tours and interactive demonstrations help community members visualize the recycling process. When people see the tangible results of their efforts, they develop stronger commitments to proper recycling practices.

Establishing Clear Policies and Regulations

Effective policy frameworks provide the structure necessary for consistent recycling operations. Well-crafted regulations specify acceptable materials, preparation requirements, and collection protocols. Clarity in these guidelines eliminates confusion and creates uniform expectations across communities.

Progressive policies incorporate both requirements and support mechanisms. While establishing clear rules, they also provide resources to help residents and businesses comply. This balanced approach fosters cooperation rather than resentment, leading to higher participation rates.

Incentivizing Participation

Behavioral economics principles demonstrate the power of structured incentive programs. When municipalities link recycling participation to tangible benefits like reduced waste fees or community improvements, engagement levels rise significantly. Digital platforms now enable sophisticated reward systems that track individual or neighborhood contributions.

The most effective incentives align with community values. Some areas see success with charitable donations tied to recycling metrics, while others prefer direct consumer rewards. Customized approaches that reflect local priorities consistently outperform generic incentive structures.

Market Development and Partnerships

Creating stable markets for recycled materials requires proactive industry engagement. Forward-thinking manufacturers now view recycled content as both an environmental imperative and a competitive advantage. Strategic partnerships between material processors and end-users help stabilize pricing and ensure consistent demand.

Innovative offtake agreements are transforming material markets. Long-term contracts with volume commitments give processors the confidence to invest in advanced equipment. These partnerships create virtuous cycles where improved material quality drives greater manufacturer adoption.