The Importance of Security Systems

Security systems, often overlooked until a crisis arises, are the silent sentinels of your safety. They act as a constant, vigilant presence, deterring potential threats and providing a crucial layer of protection. These systems are more than just alarms; they are sophisticated instruments that help to safeguard your property and loved ones. Their proactive nature makes them invaluable in maintaining peace of mind.

The various components of a comprehensive security system, from motion detectors to video surveillance, work together to create a robust defense against intruders. Properly installed and maintained, these systems can significantly reduce the risk of theft, vandalism, and other criminal activities. The peace of mind and security they provide is immeasurable.

Types of Security Systems

A wide array of security systems are available, each with unique features and benefits. From simple alarm systems that alert authorities of intrusion to sophisticated video surveillance systems that provide real-time monitoring, the options are plentiful. Choosing the right system depends heavily on individual needs and circumstances. Factors such as the size of your property, your budget, and the level of protection required play a vital role in the selection process.

Different types of systems utilize various technologies. For example, some systems use sophisticated sensors to detect movement, while others employ advanced video analytics to identify suspicious activity. Understanding the technologies underpinning each system can help you select the best option for your specific security needs. The best security system is one that provides a comprehensive and proactive approach to protecting your home.

Installation and Maintenance

Professional installation is crucial for the effectiveness of any security system. A poorly installed system can compromise its ability to function as intended, negating its protective value. Qualified technicians ensure proper wiring, placement of sensors, and compatibility with other security devices. This expertise guarantees the system's reliability and efficiency.

Regular maintenance is equally important to maintain optimal performance. This includes checking batteries, ensuring proper connectivity, and performing routine system checks. Regular maintenance not only prolongs the lifespan of your system but also ensures that it remains effective in its role as a silent sentinel. This proactive approach can prevent costly repairs and replacements down the line.

Security System Integration

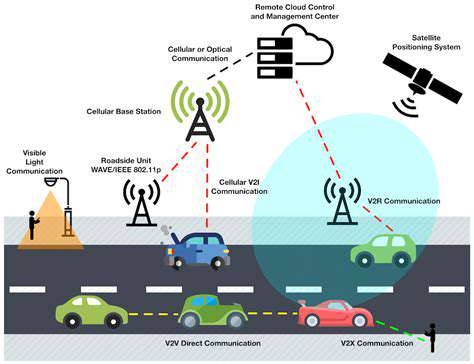

Modern security systems can be integrated with other smart home devices, creating a comprehensive interconnected security network. This integration allows for a seamless flow of information and control over various aspects of your home, enhancing overall safety and convenience. For instance, a connected security system can automatically adjust lighting, lock doors, and even alert you to potential threats via your smartphone.

By integrating your security system with smart home technology, you create a more responsive and proactive security ecosystem. This advanced integration allows for remote monitoring, real-time alerts, and automated responses to potential threats. This interconnected approach creates a more comprehensive and efficient security system that is tailored to your specific needs and lifestyle.

Identifying the Warning Signs: Common Rotor Problems

Identifying Rotor Issues: Early Detection is Key

Regularly inspecting your rotors is crucial for preventing costly repairs down the road. Early detection of potential problems, such as signs of uneven wear or the presence of cracks, can save you from a catastrophic brake failure. This proactive approach allows for timely intervention, preventing further damage and ensuring the safety and longevity of your braking system.

Ignoring early warning signs can lead to a cascade of issues, increasing the risk of accidents and expensive repairs. By understanding the subtle indicators of rotor problems, you can take the necessary steps to maintain the optimal performance and safety of your vehicle's braking system.

Uneven Wear: A Telltale Sign of Trouble

One of the most common rotor problems is uneven wear. This occurs when the rotor isn't absorbing friction evenly across its surface, often due to misalignment or improper braking techniques. Look for a noticeable difference in the thickness or grooves along the rotor's circumference; a visual inspection can reveal these irregularities. Uneven wear can lead to reduced braking efficiency and increased stopping distances, making it a significant safety concern.

Wobbly Pedal: A Potential Indicator

A wobbly or pulsating brake pedal is a strong indicator of a problem with the rotors or calipers. This sensation can arise from warped or damaged rotors that don't provide consistent braking force. Identifying this symptom is vital as it often precedes more severe issues, such as complete brake failure. It's crucial to address this immediately to avoid potential accidents and further damage to the braking system.

Visible Cracks: A Major Safety Hazard

Visible cracks on the rotor's surface are a serious warning sign. These cracks compromise the integrity of the rotor, making it less effective and potentially dangerous. They can also lead to further fracturing during braking, which can result in catastrophic brake failure. Thorough visual inspections should be a part of your routine vehicle maintenance. If cracks are detected, immediate professional intervention is necessary.

Grooves and Scoring: Signs of Excessive Friction

Grooves and scoring on the rotor surface often indicate excessive friction between the brake pads and rotor. This friction can lead to uneven wear and tear, potentially compromising the rotor's structural integrity. These markings are often accompanied by a screeching or grinding sound during braking. This is an indication that the friction is too high and the rotor is being damaged. Prompt attention is required to prevent further damage and restore optimal braking performance.

Warped Rotors: Impaired Braking Performance

Warped rotors are a common issue that significantly impairs braking performance. They result from uneven heating and cooling during braking, leading to a distorted shape. This distortion can cause a pulsating sensation in the brake pedal and reduce the effectiveness of the braking system. Driving with warped rotors can significantly increase stopping distances and compromise safety. Warped rotors necessitate professional repair or replacement.

Beyond the Visual: Assessing Rotor Condition with Professional Tools

Understanding Rotor Vibration Analysis

Rotor vibration analysis is a critical aspect of assessing rotor condition, moving beyond simply observing visual cues. It involves using sophisticated tools to measure and analyze the vibrations generated by the rotor as it spins. This method provides a deep dive into the underlying mechanical conditions, allowing for Early detection of potential problems that might not be immediately apparent through visual inspection. Understanding the patterns and frequencies of these vibrations is crucial in pinpointing anomalies and predicting potential failures.

By analyzing the amplitude, frequency, and phase of the vibrations, technicians can identify imbalances, misalignments, bearing defects, and other issues that could lead to catastrophic rotor failure. This proactive approach allows for timely maintenance and significantly reduces the risk of costly downtime and safety hazards.

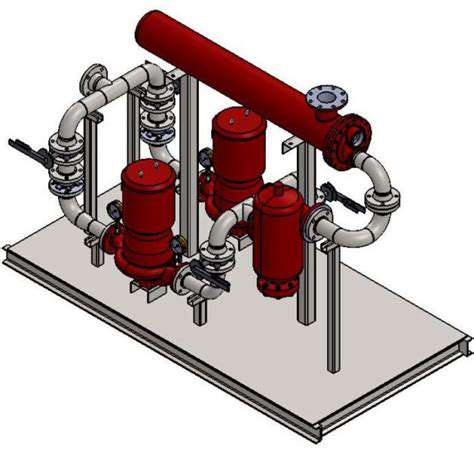

The Role of Advanced Sensors and Instrumentation

Modern rotor condition assessment relies heavily on advanced sensors and instrumentation. These tools are designed to capture precise data about the rotor's vibrational characteristics in real-time. From accelerometers that measure acceleration to proximity sensors that detect changes in proximity, these instruments provide detailed information about the mechanical state of the rotor.

Sophisticated data acquisition systems are also essential, allowing for the storage and processing of the vast amounts of data generated by these sensors. This processed data is used to generate detailed reports and charts, providing valuable insights into the rotor's health.

Analyzing Vibration Patterns for Early Detection

Examining vibration patterns is paramount in early rotor condition assessment. By identifying anomalies in the frequency spectrum, such as sudden increases in specific frequencies, technicians can detect subtle signs of impending failure. These deviations from the expected vibration profile can indicate issues like looseness, misalignment, or bearing wear.

Experienced analysts can use sophisticated software and algorithms to interpret these patterns and isolate the root causes of the anomalies. This allows for proactive maintenance scheduling, reducing the risk of unexpected failures and costly repairs.

Importance of Predictive Maintenance Strategies

Rotor condition assessment is intrinsically linked to predictive maintenance strategies. By analyzing vibration data, technicians can predict potential failures before they occur, enabling proactive maintenance interventions. This approach minimizes downtime, reduces repair costs, and enhances operational safety.

Predictive maintenance allows for optimized maintenance schedules, focusing resources on preventing failures rather than reacting to them. This proactive approach leads to significant cost savings and improved operational efficiency.

Visual Inspection as a Complementary Tool

While advanced tools are crucial, visual inspection remains an important complementary method in rotor condition assessment. Visual checks can identify obvious signs of damage, such as cracks, corrosion, or misalignments, that might not be immediately apparent in the vibration data. A thorough visual examination can help to identify critical areas requiring further investigation using advanced tools.

The Significance of Regular Maintenance Schedules

Implementing regular maintenance schedules is fundamental to maintaining optimal rotor condition. Scheduled inspections, combined with vibration analysis, allow technicians to identify and address potential issues before they escalate into major problems. This preventative approach minimizes the risk of catastrophic failures and ensures the long-term reliability and safety of the equipment.

Regular maintenance also allows for the early detection of subtle changes in the rotor's behavior, giving technicians time to implement necessary adjustments or repairs. This approach not only extends the lifespan of the equipment but also minimizes the potential for costly downtime.

Expert Interpretation and Reporting

Accurate interpretation of the data generated by the various tools used for rotor condition assessment is crucial. Expert technicians with specialized training are needed to analyze the vibration patterns, identify anomalies, and provide meaningful reports. These reports should clearly communicate the findings, suggest corrective actions, and provide recommendations for future maintenance.

Comprehensive reporting ensures that all stakeholders, from maintenance personnel to engineering managers, have a clear understanding of the rotor's condition and the necessary steps to maintain its optimal performance. This clarity is vital for informed decision-making and effective preventative maintenance strategies.

Preventing Problems: Maintaining Optimal Rotor Health

Regular Inspections for Early Detection

Routine inspections are crucial for identifying potential issues with rotors before they escalate into major problems. Regular visual checks, coupled with the use of specialized tools and techniques, can pinpoint early signs of wear, damage, or imbalance. This proactive approach allows for timely intervention, preventing costly repairs and downtime, ensuring the long-term health and efficiency of your rotor systems.

Thorough inspections should cover the entire rotor assembly, including bearings, seals, and mounting points. Any deviation from the expected condition, such as unusual noises, vibrations, or visible wear patterns, should be flagged and investigated promptly by qualified personnel. Early detection of problems allows for preventative maintenance, reducing the risk of catastrophic failure.

Proper Lubrication Practices

Maintaining optimal lubrication is paramount to rotor health. The correct type and amount of lubricant, applied at the prescribed intervals, ensures smooth operation and minimizes friction. Insufficient lubrication can lead to accelerated wear and tear, damaging the rotor and its components.

Using the correct lubricant viscosity for the operating temperature and environment is critical. Incorrect lubrication can lead to premature bearing failure, resulting in costly repairs or even catastrophic rotor failure. Proper lubrication protocols not only enhance rotor performance but also significantly prolong its lifespan.

Monitoring Vibration Levels

Continuous monitoring of vibration levels is a vital aspect of rotor maintenance. Slight increases in vibration can signal imbalances, misalignments, or other underlying issues. Employing vibration analysis tools allows for precise identification of the source and severity of the problem, enabling proactive corrective measures before significant damage occurs.

Regular vibration measurements help identify potential problems early, allowing for timely intervention and preventing costly repairs. By monitoring vibration levels, you can proactively address issues before they escalate into major rotor failures, minimizing downtime and maximizing equipment lifespan.

Balancing Rotor Assemblies

Rotor imbalance can lead to excessive vibrations, potentially causing damage to the rotor itself and surrounding equipment. Regular balancing ensures the rotor's mass distribution is uniform, reducing vibrations and extending its operational lifespan. Professional balancing procedures are essential to achieving optimal rotor performance.

Addressing Misalignment Issues

Proper alignment of the rotor assembly with its supporting structures is crucial for preventing excessive stress and wear. Misalignment can lead to premature failure of bearings, seals, and other components. Employing sophisticated alignment tools and techniques allows for precise alignment, ensuring optimal rotor performance and minimizing potential damage.

Temperature Monitoring and Management

Monitoring rotor temperatures is essential for detecting overheating, a common indicator of potential problems. Overheating can damage bearings and other components, leading to rotor failure. Implementing temperature monitoring systems allows for proactive identification of high temperatures, enabling timely intervention and preventing costly breakdowns. Regular temperature checks and analysis are critical for maintaining optimal rotor health and preventing costly repairs.

The Cost of Neglect: Why Regular Inspections Matter

Preventive Maintenance Saves Money in the Long Run

Regular inspections, far from being an added expense, are a vital investment in the longevity and safety of your vehicle. By catching potential issues early, you can avoid costly repairs down the line. Think of it like maintaining a healthy lifestyle – a little preventative care now can save you from significant problems and financial strain later. Ignoring minor problems often leads to more extensive and expensive repairs, ultimately costing you more in the long run.

Routine checks allow mechanics to address issues before they escalate into major problems. This proactive approach can save you hundreds, if not thousands, of dollars in repair costs over the life of your vehicle. Furthermore, the peace of mind knowing your vehicle is well-maintained is priceless.

Early Detection Prevents Accidents

Ignoring warning signs, like squeaking brakes or unusual vibrations, can lead to catastrophic failure. Regular inspections allow mechanics to identify these potential hazards before they cause an accident. A simple inspection can prevent a costly accident and protect you and others on the road.

By addressing issues like worn brake pads or damaged rotors early, you significantly reduce the risk of a sudden brake failure, which can lead to a serious collision. Regular inspections are crucial for maintaining road safety.

Safety First: Protecting Yourself and Others

Brake malfunctions can lead to catastrophic consequences, putting you and others on the road at risk. Regular inspections provide an essential safety net, ensuring your brakes are functioning optimally and capable of stopping your vehicle effectively. Safety should always be the top priority when it comes to maintaining your vehicle.

A properly functioning braking system is essential for avoiding accidents. Regular inspections help to maintain this critical aspect of vehicle safety, preventing potential hazards and keeping you and other drivers safe on the road.

Understanding Brake System Components

A comprehensive inspection goes beyond just visual checks. It involves examining various components of the brake system, including brake pads, rotors, calipers, and brake lines. Understanding how these components interact is crucial for identifying potential issues before they manifest as a major problem.

A mechanic's expertise in diagnosing brake system problems is essential. They can identify subtle wear and tear or signs of damage to these critical components, ensuring that your braking system is in peak condition.

The Role of Brake Fluid and its Importance

Brake fluid is a crucial element in the braking system. Its condition and level directly impact the effectiveness of your brakes. Regular inspections include checking the brake fluid level and condition, ensuring it's not contaminated or deteriorated. Improper brake fluid can lead to brake failure.

Importance of Following Manufacturer Recommendations

Manufacturers provide specific recommendations for brake inspection intervals. Adhering to these guidelines is essential for maintaining your vehicle's warranty and ensuring its longevity. Following manufacturer recommendations helps to maintain the optimal performance and safety of your vehicle.

Ignoring these recommendations can void your warranty and lead to more expensive repairs down the line. Your vehicle's manufacturer has designed the braking system with specific maintenance requirements in mind. Understanding and following these recommendations is a key element in preventing costly problems.

The Cost-Effectiveness of a Well-Maintained Vehicle

Investing in regular brake inspections is an investment in your safety and the longevity of your vehicle. A well-maintained vehicle is not only safer but also more reliable and cost-effective in the long run. By preventing potential problems, you avoid costly repairs and ensure your vehicle operates efficiently.

A well-maintained vehicle often requires fewer repairs, resulting in lower overall maintenance costs. The savings you accumulate through preventative maintenance far outweigh the cost of regular inspections. It's a smart financial decision for vehicle owners.