Emission Monitoring and Continuous Improvement

Implementing Effective Monitoring Systems

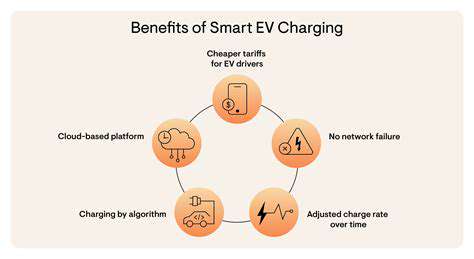

A crucial aspect of reducing emissions in car production is establishing robust emission monitoring systems. These systems need to be comprehensive, encompassing various stages of the manufacturing process, from raw material sourcing to final vehicle testing. Implementing real-time data collection and analysis tools allows manufacturers to identify emission hotspots early in the process, enabling prompt corrective actions and preventing the production of vehicles exceeding emission targets. This proactive approach not only adheres to environmental regulations but also significantly reduces the cost of rectifying issues later on in the production cycle.

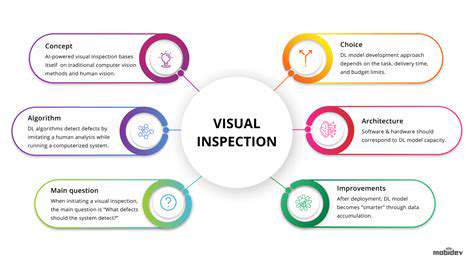

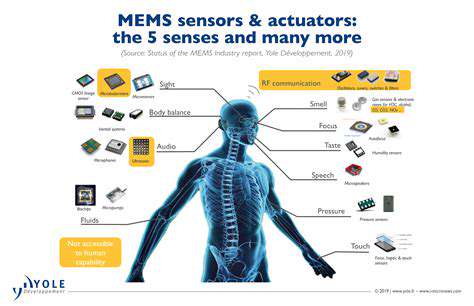

Careful selection of monitoring equipment is essential. The equipment must be accurate, reliable, and capable of providing detailed data on key emission parameters. Calibration and maintenance schedules should be strictly adhered to to ensure data integrity. Furthermore, the systems should be designed to integrate seamlessly with existing production lines and management software, facilitating efficient data analysis and reporting. This integration streamlines the entire process, enabling informed decision-making and accelerating the continuous improvement cycle.

Continuous Improvement Through Data-Driven Strategies

Emission monitoring data provides a wealth of information that can be leveraged for continuous improvement initiatives. Analyzing trends in emission levels, identifying root causes of deviations from targets, and implementing targeted interventions are key elements of a successful continuous improvement strategy. This data-driven approach allows for a deeper understanding of the manufacturing process, pinpointing areas for optimization and enabling more efficient resource allocation. Detailed analysis of the data can reveal subtle patterns and relationships that might otherwise remain hidden, leading to innovative solutions for emission reduction.

Regular audits and reviews of the monitoring systems and associated data are crucial for identifying areas for improvement. This involves evaluating the effectiveness of existing procedures, assessing the performance of employees, and identifying potential technological advancements that could further reduce emissions. Feedback loops are essential, allowing adjustments to be made based on the latest data and facilitating a cycle of continuous improvement. By fostering a culture of continuous learning and improvement, manufacturers can achieve significant reductions in emissions over time, aligning production practices with environmental sustainability goals.

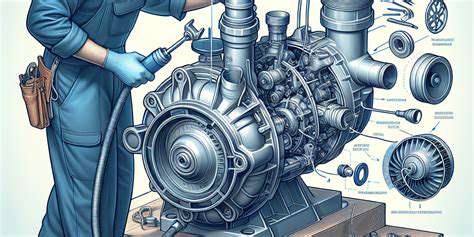

Implementing standardized protocols and best practices across all production facilities is vital for maintaining consistency in emission reduction efforts. This involves training employees on the proper use of monitoring equipment and the interpretation of data. Establishing clear communication channels and a collaborative environment between different departments—engineering, quality control, and production—is also critical for effective implementation of emission reduction strategies. This collaborative approach allows for the sharing of knowledge, best practices, and insights, leading to improved decision-making and more sustainable production processes.

Data visualization tools play a key role in effectively communicating monitoring results and driving improvements. Visual representations of emission data help stakeholders understand trends and patterns more easily. This improved understanding fosters better communication and collaboration, enabling more informed decisions and faster problem-solving. The use of dashboards and reports helps track progress toward emission reduction goals and facilitates a culture of accountability.

Active engagement with industry experts and participation in relevant forums can provide valuable insights and best practices for emission monitoring and reduction. Sharing knowledge and experiences with peers can accelerate the adoption of innovative solutions and foster a culture of continuous improvement within the industry. This collaborative approach can lead to the development of industry-wide standards and best practices, further driving emission reduction efforts.