Recycling and Reuse Strategies for End-of-Life Vehicles (ELVs)

Effective Collection and Sorting Systems

Implementing robust collection and sorting systems for end-of-life vehicles (ELVs) is crucial for maximizing resource recovery. These systems must be designed to efficiently separate valuable materials like metals, plastics, and rubber from hazardous components like batteries and fluids. Proper sorting protocols, coupled with advanced technologies for material identification, ensure that valuable materials are salvaged and hazardous materials are managed safely and responsibly, minimizing environmental risks and maximizing the economic benefits of recycling.

Dedicated collection points or mobile collection units can streamline the process, while clear labeling and segregation protocols help ensure that materials are sorted correctly at the source. This minimizes contamination and maximizes the quality of recycled materials, leading to higher recovery rates and reduced costs associated with downstream processing.

Material Recovery and Processing

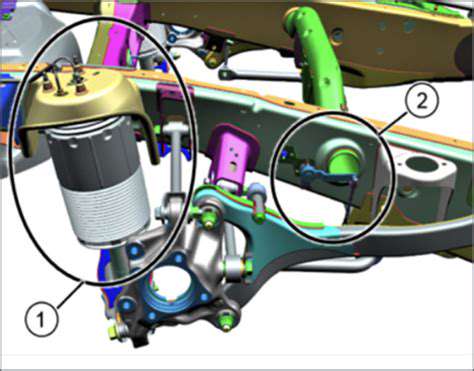

Advanced material recovery and processing techniques are essential to extract valuable components from ELVs. This includes techniques such as shredding, mechanical separation, and chemical processes to extract specific materials. Optimizing these processes is key to achieving high recovery rates for critical raw materials like steel, aluminum, and copper, while also ensuring the safe handling of hazardous materials.

Recycling facilities need to be equipped with advanced processing technologies to handle the diverse range of materials found in ELVs, including specialized equipment for separating different types of plastics and rubber. This ensures that the extracted materials meet industry standards for quality and purity, enhancing their usability in secondary applications.

Hazardous Waste Management

ELVs contain hazardous materials like lead-acid batteries, catalytic converters, and various fluids. Effective hazardous waste management is critical to prevent environmental contamination and ensure the safety of workers involved in the recycling process. Proper handling, storage, and disposal of these materials are essential steps to comply with environmental regulations and minimize potential risks.

Rigorous protocols for handling hazardous components, including specialized training for personnel, are essential. This includes the use of appropriate personal protective equipment (PPE) and adherence to strict safety procedures during all stages of the process, from dismantling to final disposal.

Economic Incentives and Policies

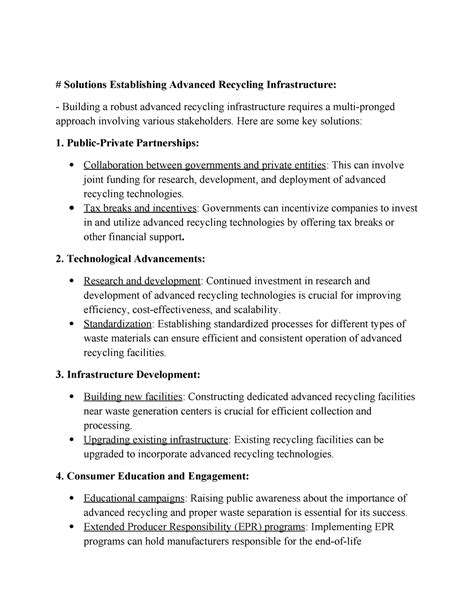

Incentivizing the recycling of ELVs through economic policies can significantly boost participation and resource recovery. Government subsidies, tax breaks, and deposit-refund schemes can encourage vehicle owners to participate in recycling programs, driving up collection rates and material recovery.

Clear and transparent policies regarding the handling and disposal of ELVs can foster a sustainable approach to waste management, helping to create a circular economy for this sector. This requires collaboration between governments, industry, and consumers to ensure the effective implementation of these policies.

Public Awareness and Education

Educating the public about the importance of recycling ELVs and the benefits of a circular economy can significantly impact participation rates. Raising awareness about the environmental and economic advantages of recycling can encourage vehicle owners to engage in responsible disposal practices, leading to a substantial increase in the volume of materials recovered.

Educational campaigns can highlight the potential of ELVs to become a source of valuable raw materials for new products, contributing to a more sustainable future. Public awareness campaigns can also focus on the safety and health implications of improper ELV disposal, demonstrating the importance of adhering to proper recycling protocols.

Technological Advancements

Technological advancements play a critical role in improving recycling and reuse strategies for ELVs. Innovations in material separation techniques, such as advanced magnetic separators and optical sorting systems, can significantly enhance the efficiency and effectiveness of the recycling process. These advancements can help maximize the recovery of valuable materials while minimizing environmental risks.

The development and implementation of new technologies, including automated dismantling systems and improved sensor technologies for material identification, can increase the speed and precision of the recycling process. This will lead to significant cost savings and improved sustainability.

Community Engagement and Partnerships

Building strong partnerships between government agencies, recycling facilities, and the community can foster a more effective and sustainable recycling process. This includes establishing community collection points and creating awareness programs to encourage public participation in ELV recycling initiatives. Working collaboratively with local businesses can also help identify and address any logistical or economic challenges related to implementing recycling programs.

Partnerships can facilitate the sharing of best practices and resources among stakeholders, fostering a sense of collective responsibility in ensuring the sustainable management of ELVs and promoting the circular economy principles.