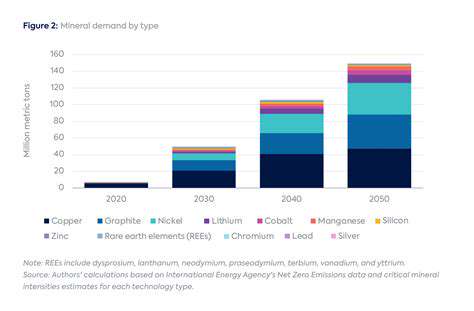

The Growing Demand for Critical Minerals

The Rise of Critical Thinking Skills

In today's rapidly evolving landscape, the ability to think critically has become indispensable. Modern professionals must constantly analyze complex information, assess competing arguments, and make sound judgments. Those who master these cognitive abilities gain a significant advantage in both personal and professional spheres. Educational institutions worldwide are responding by integrating critical thinking exercises into their curricula.

Identifying logical fallacies, evaluating source credibility, and constructing coherent arguments represent essential skills in our information-rich society. Employers increasingly value candidates who demonstrate these capabilities, particularly in fields requiring complex problem-solving.

Impact on Education Systems

Forward-thinking educators are redesigning learning experiences to emphasize analytical skills over rote memorization. Classrooms now feature more Socratic discussions, case study analyses, and evidence-based debates. This pedagogical shift recognizes that critical thinking develops through practice rather than passive absorption of information. Students engaged in this approach show improved ability to apply knowledge to real-world situations.

The transformation extends beyond higher education, with primary schools introducing age-appropriate critical thinking exercises. This long-term investment aims to create future citizens capable of navigating an increasingly complex global landscape.

Demand in the Workplace

Corporate leaders consistently rank analytical reasoning among their most sought-after employee attributes. From diagnosing medical conditions to optimizing supply chains, professionals across industries rely on structured problem-solving approaches. Companies investing in critical thinking training report higher productivity and better decision-making at all organizational levels.

Applications in Everyday Life

Critical thinking extends far beyond professional contexts, influencing personal decisions about health, finances, and relationships. Consumers face constant information overload when evaluating products, services, and news sources. Developing discernment skills helps individuals avoid scams, make informed purchases, and engage meaningfully with societal issues.

The ability to question assumptions and recognize cognitive biases proves invaluable when navigating modern digital environments. Social media platforms amplify misinformation, making critical evaluation of content essential for responsible digital citizenship.

Technological Advancements and Critical Thinking

While technology provides unprecedented access to information, it also presents new challenges for information literacy. The rise of deepfakes, algorithmic bias, and synthetic media requires sophisticated evaluation skills. Educational programs must evolve to address these emerging threats to rational discourse.

Future Implications of the Trend

The growing emphasis on critical faculties signals a societal recognition of their importance. Cultivating these skills at scale could produce more informed electorates, more ethical businesses, and more resilient communities. As automation handles routine tasks, human value will increasingly derive from higher-order cognitive abilities.

Educational reformers advocate for assessment methods that measure analytical depth rather than factual recall. This paradigm shift may ultimately redefine success in the 21st century knowledge economy.

The Environmental Footprint of Extraction and Processing

Raw Material Acquisition

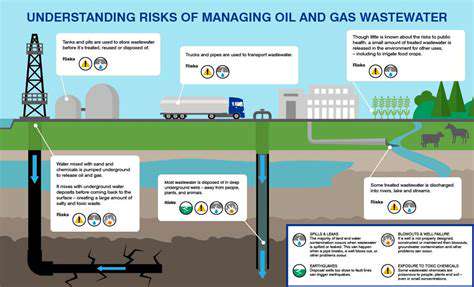

Securing battery minerals like lithium and cobalt involves environmentally intensive processes with global consequences. Open-pit mining operations disrupt ecosystems, while inadequate safeguards often lead to water table contamination. The carbon footprint compounds when factoring in international transportation of raw materials between extraction sites and processing facilities.

Material purity significantly affects downstream efficiency, as impurities necessitate additional refining steps. Emerging extraction technologies promise to reduce environmental harm while improving yield quality, though widespread adoption remains limited by economic factors.

Processing and Refining

Transforming raw ores into battery-grade materials involves energy-intensive chemical processes with substantial emissions. Many facilities still rely on fossil-fueled energy, though some pioneers are transitioning to renewable sources. Proper treatment of processing byproducts remains a challenge, particularly in regions with lax environmental regulations.

Innovations in hydrometallurgical techniques show promise for reducing both energy consumption and hazardous waste. Industry leaders recognize that cleaner processing methods represent both an environmental necessity and long-term competitive advantage.

Manufacturing Battery Cells

Cell production facilities consume massive amounts of energy for controlled-environment operations. The precision required for electrode preparation and assembly generates material waste that must be carefully managed. Some manufacturers now employ closed-loop systems to recover and reuse production byproducts.

Battery architecture continues evolving, with new designs optimizing both performance and sustainability. Solid-state batteries may eventually reduce reliance on volatile electrolytes while improving energy density.

Transportation and Logistics

The globalized battery supply chain involves extensive material movement across continents, primarily via carbon-intensive shipping and trucking. Some companies are experimenting with electric heavy freight vehicles for regional distribution, though infrastructure limitations persist.

Supply chain optimization software helps reduce unnecessary transportation through better inventory management and production planning. Localized battery gigafactories could eventually minimize cross-continent shipping requirements.

End-of-Life Management

Improper battery disposal poses serious environmental hazards due to toxic components. While recycling infrastructure grows, collection systems remain inconsistent across regions. Second-life applications for degraded EV batteries in stationary storage show promise for extending useful life before recycling.

Advanced sorting and separation technologies are improving recovery rates for valuable metals. Standardized battery designs would facilitate more efficient disassembly and material recovery at scale.

Overall Impact on Ecosystems

The cumulative environmental effects span from local mining communities to global climate systems. Responsible sourcing initiatives aim to mitigate habitat destruction, while cleaner production methods reduce atmospheric emissions. Lifecycle analysis tools help manufacturers identify high-impact areas for targeted improvements.

International cooperation remains essential for establishing consistent environmental standards across the supply chain. Consumer demand for sustainable products continues driving positive change throughout the industry.

Supply Chain Diversification and Infrastructure Development

Supply Chain Resilience

Geopolitical tensions and pandemic disruptions exposed vulnerabilities in concentrated supply networks. Leading manufacturers now pursue multi-continent sourcing strategies to mitigate regional risks. This includes developing alternative mineral sources and establishing redundant manufacturing capacity across different jurisdictions.

Strategic stockpiling of critical materials provides buffer against short-term disruptions, while long-term contracts with diversified suppliers ensure stable access. Digital supply chain monitoring enables rapid response to emerging challenges anywhere in the network.

Infrastructure Development for Sustainable Production

Building battery production capacity requires coordinated investment in physical and human capital. Renewable-powered manufacturing campuses are becoming the standard for new facilities, supported by onsite energy storage solutions. Workforce development programs train technicians in specialized battery manufacturing techniques.

Governments play a crucial role through targeted infrastructure spending and policy frameworks that encourage sustainable practices. Public-private partnerships accelerate the development of necessary supporting infrastructure.

Raw Material Acquisition and Processing

Alternative extraction methods like direct lithium extraction reduce land disturbance compared to traditional mining. Researchers continue exploring more abundant materials to reduce reliance on geopolitically sensitive resources. Processing facility locations are being optimized to minimize transportation distances between mining and refining operations.

Blockchain initiatives improve traceability throughout supply chains, addressing both ethical and quality concerns. Certification programs help buyers identify responsibly sourced materials.

Manufacturing Capacity Expansion and Technology Innovation

Modular factory designs allow for scalable production capacity that can adjust to market demands. Automation and AI-driven quality control systems enhance production consistency while reducing waste. Continuous process improvements drive down costs through incremental efficiency gains.

Joint ventures between automakers and battery specialists accelerate technology transfer and production scaling. Standardized battery formats enable economies of scale across vehicle platforms.

Regulatory and Policy Frameworks

Harmonized international standards would facilitate smoother cross-border battery trade while maintaining environmental protections. Incentive programs encourage domestic battery ecosystem development without creating market distortions. Clear recycling mandates ensure proper end-of-life management across jurisdictions.

Trade agreements increasingly include provisions for responsible battery supply chains, creating alignment among trading partners. Tax policies are being adjusted to favor sustainable production methods and circular economy principles.