Exterior Maintenance: Protecting Your EV's Investment

Washing Your Electric Vehicle

Regular washing is crucial for maintaining the exterior of your electric vehicle (EV). Washing removes dirt, grime, and road salt, preventing these elements from causing damage to the paint and potentially leading to rust. Use a soft cloth or sponge and a gentle car wash solution. Avoid harsh chemicals or brushes that could scratch the delicate paint finish. Thoroughly rinse the vehicle to remove all traces of soap, and then dry it completely to prevent water spots.

Protecting your EV's paint job from environmental elements is vital for preserving its aesthetic appeal and preventing potential damage. Using a quality car wash solution and drying the vehicle meticulously can significantly extend the life of your EV's exterior.

Protecting Your EV's Finish

Applying a quality wax or sealant can significantly enhance the longevity and appearance of your EV's paint. These protective layers create a barrier against UV rays, bird droppings, and other environmental aggressors that can damage the paint. Regular waxing or sealing, ideally every 3-6 months, can help maintain the shine and prevent the build-up of contaminants that can lead to oxidation and dullness.

Addressing Scratches and Dents

Minor scratches and dents are inevitable, especially when parking in tight spaces. Immediate attention to these issues can prevent further damage. For minor scratches, consider using a touch-up paint pen that matches the vehicle's color. For more significant damage, consult a professional detailer or body shop to ensure proper repair and avoid compromising the integrity of the vehicle's finish.

Protecting Your Wheels and Tires

The wheels and tires of your EV are subjected to significant wear and tear. Regular cleaning and inspection are essential to maintain their condition. Use specialized wheel cleaner and tire shine to keep them looking their best. Inspect for any signs of damage, such as punctures or uneven wear, and address these issues promptly to prevent further problems. Proper tire pressure is also crucial for optimal performance and safety.

Cleaning Windows and Trim

Clean your EV's windows and trim regularly to maintain visibility and aesthetic appeal. Use a glass cleaner specifically designed for vehicles to prevent streaks and ensure a clear view. Pay attention to the trim pieces, as these are susceptible to dirt and debris accumulation. Use a soft cloth and appropriate cleaning solutions to avoid scratching the delicate surfaces.

Exterior Detailing and Maintenance Schedule

Establishing a regular exterior detailing schedule is key to preserving the investment you've made in your EV. This schedule should incorporate washing, waxing, and wheel cleaning. The frequency of these tasks will depend on your driving habits and the environmental conditions you encounter. For example, more frequent washing might be necessary if you drive in dusty or salty environments. Consider using a detailing checklist to help you remember all the important steps for maintaining your EV's exterior.

Vertical landing systems are rapidly transforming the aviation industry, offering a paradigm shift in aircraft operations. These systems promise increased safety, reduced congestion at airports, and the potential for more efficient and sustainable air travel. The ability to land and take off vertically allows for the utilization of smaller, more nimble aircraft, which can access a wider range of locations and operate in environments previously inaccessible to traditional aircraft.

Interior Cleaning and Maintenance: A Clean and Comfortable Drive

Interior Cleaning Techniques

Maintaining a clean and well-maintained interior is crucial for preserving its aesthetic appeal and longevity. Proper cleaning techniques can significantly extend the life of your furniture and other interior items, preventing premature wear and tear. Regular dusting, vacuuming, and spot cleaning are essential steps to prevent the accumulation of dirt, dust mites, and other allergens.

Different materials require different cleaning methods. For example, wood furniture often benefits from a gentle dusting with a soft cloth and occasional polishing with a dedicated wood cleaner. Upholstered furniture typically requires vacuuming with a brush attachment and spot cleaning with appropriate solutions. Understanding these nuances is critical to avoiding damage and ensuring a long-lasting clean interior.

Maintaining Upholstery

Upholstered furniture is a significant investment, and maintaining its quality is paramount. Regular vacuuming with a brush attachment helps remove loose dirt and dust. Spot cleaning is crucial for addressing spills and stains promptly. Using the right cleaning solutions for the fabric type is essential to prevent discoloration or damage. A professional upholstery cleaning service is recommended every few years to deep clean and refresh the fabric.

Knowing your upholstery material is key. Linen, cotton, or velvet will require different cleaning solutions. Leather, while often durable, needs specialized care to prevent cracking or drying. Always test any cleaning solution in an inconspicuous area before applying it to the entire surface. Taking preventative measures like covering furniture during construction or moving can help maintain upholstery cleanliness.

Protecting Woodwork

Woodwork adds character and warmth to any interior space. Protecting this valuable asset is essential to maintaining its beauty and longevity. Regular dusting with a soft cloth and a microfiber duster is crucial to preventing the accumulation of dust and dirt. This helps in preserving the natural sheen of the wood and preventing scratches.

Protecting wood from moisture is equally important. Avoid placing furniture near water sources or in areas prone to moisture damage. Use coasters or placemats under items to prevent water stains or damage from spills. Addressing moisture issues promptly is essential to prevent warping and mold or mildew formation. Using appropriate wood-care products can further protect the finish.

Cleaning Glass and Mirrors

Glass and mirrors reflect light and add a sense of spaciousness to a room. Maintaining their clarity is important for maximizing the impact of these elements. Regular cleaning with a soft cloth and glass cleaner is necessary to remove smudges, fingerprints, and dust. Using a microfiber cloth helps avoid streaks and ensures a streak-free finish.

Cleaning glass and mirrors should be done systematically, focusing on each surface thoroughly. Pay close attention to corners and edges where dust and debris tend to accumulate. Using appropriate cleaning solutions for the surface type is essential to prevent damage and maintain its shine. Cleaning glass and mirrors is a task that shouldn't be overlooked for a sparkling home.

Addressing Common Interior Maintenance Issues

Maintaining a clean interior often involves addressing various issues. One common concern is the accumulation of dirt and dust in hard-to-reach areas. Using appropriate cleaning tools and techniques is crucial to tackling these challenges effectively. Regular maintenance is key to preventing more significant issues. This can involve addressing pet hair, spills, and other common problems promptly.

Another key aspect is addressing potential moisture issues. Checking for leaks, damp spots, and condensation is crucial to preventing mold and mildew growth. Addressing these problems early can save you considerable time and money, preventing more significant damage. Regular inspections and maintenance routines are essential to maintaining the integrity of your interior.

Regular Inspections and Preventative Maintenance: Proactive Care for Optimal Performance

Understanding the Importance of Regular Inspections

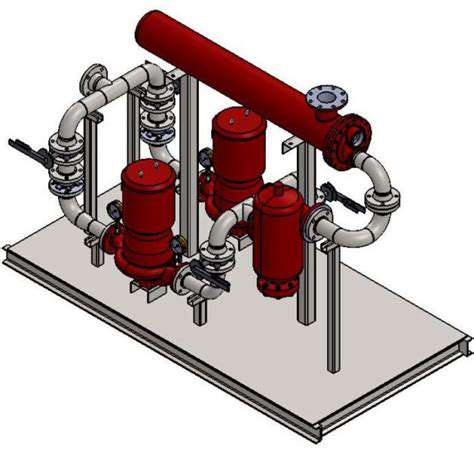

Regular inspections are crucial for maintaining optimal performance and extending the lifespan of equipment. These inspections, often conducted by trained technicians, allow for the early detection of potential problems before they escalate into costly repairs or even catastrophic failures. By proactively identifying and addressing minor issues, you can prevent significant downtime and ensure that your equipment operates at peak efficiency. This proactive approach saves money in the long run by avoiding major repairs and unexpected breakdowns.

Regular inspections also help to maintain safety standards. Early detection of faulty components or wear and tear can prevent accidents and injuries. This is particularly critical in industries where machinery operates at high speeds or involves hazardous materials. A well-maintained system reduces the risks associated with equipment failure, protecting both personnel and the surrounding environment.

Identifying Potential Issues Through Preventative Maintenance

Preventative maintenance goes beyond simply visual inspections. It involves a systematic approach to checking equipment components and performing scheduled tasks, like lubrication, cleaning, and adjustments. These proactive measures help to prevent potential failures and maintain optimal performance.

Regular lubrication, for example, reduces friction and wear, extending the lifespan of moving parts. Cleaning removes debris and contaminants that can contribute to corrosion and damage. Adjustments ensure that equipment operates within its intended parameters and prevents parts from becoming misaligned or damaged.

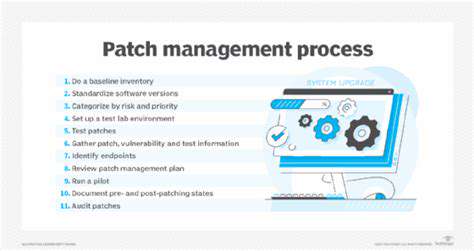

Scheduling Inspections and Maintenance Activities

Developing a comprehensive schedule for inspections and preventative maintenance activities is essential for optimal performance. This schedule should be tailored to the specific needs of your equipment, taking into account factors like usage frequency, operating conditions, and environmental factors. Consider incorporating a computerized maintenance management system (CMMS) to track schedules, manage resources, and generate reports.

Regularly review and update your schedule based on the results of inspections. This ensures that your preventative maintenance plan remains effective and that you're addressing any emerging trends or issues. Proper planning allows for efficient allocation of resources and minimizes disruptions to your operations.

The Role of Trained Technicians in Inspection and Maintenance

Trained technicians play a critical role in ensuring the effectiveness of regular inspections and preventative maintenance. Their expertise allows for a thorough and accurate assessment of equipment condition, identifying potential problems that might be missed by untrained personnel. Their knowledge of the specific equipment and procedures is paramount in preventing costly errors and ensuring accurate diagnoses.

Furthermore, trained technicians are equipped to perform the necessary maintenance tasks, using the correct tools and techniques to address any identified issues. They can diagnose problems effectively and implement solutions that address the root cause, preventing future occurrences.

Cost Savings and Return on Investment

Implementing a robust program of regular inspections and preventative maintenance can lead to significant cost savings. By proactively addressing minor issues, you avoid the expense of major repairs, extended downtime, and potential safety incidents. These proactive measures can translate to substantial returns on investment, as they help minimize the risk of costly equipment failures and ensure consistent and reliable performance.

The long-term cost savings associated with preventative maintenance often outweigh the initial investment in training and tools. The overall return on investment includes not only reduced repair costs but also increased operational efficiency and productivity.

The Impact on Safety and Efficiency

Regular inspections and preventative maintenance directly impact safety and efficiency. By identifying and rectifying potential hazards early on, you create a safer work environment for all personnel. This proactive approach minimizes the risk of accidents and injuries, ensuring the well-being of your employees and mitigating potential liabilities.

Furthermore, maintaining equipment at peak performance through preventative maintenance improves overall efficiency. Consistent operation, reduced downtime, and minimized repairs contribute to a more streamlined workflow and increased productivity. This translates to a positive impact on your bottom line and overall business performance.